Finding a reliable injection moulding components manufacturer requires evaluating their technical expertise, quality control systems, and experience with your specific industry and project requirements.

The injection moulding components manufacturing industry is a critical part of modern manufacturing. In 2025, the market for injection molded parts in China alone was valued at 3,247.8 billion yuan, with key sectors like automotive (31.6%) and electronics (28.3%) driving demand . This market's complexity means that simply finding a supplier is not enough; you must find a true partner capable of delivering precision, consistency, and value. This guide is designed to help engineers, procurement specialists, and product developers systematically navigate the selection process, from understanding core technical parameters to implementing strategies for cost optimization and quality assurance. By focusing on the critical factors that separate competent manufacturers from exceptional ones, you can build supply chain partnerships that enhance product quality and project success.

Introduction

Injection moulding is the backbone of mass-producing high-volume, high-precision plastic and metal components. The quality and consistency of these injection moulding components directly impact the performance, cost, and lifecycle of the final product. Partnering with the right manufacturer is not just a procurement decision; it is a strategic investment in your product's success. A capable partner provides more than just parts—they offer manufacturing design (DfM) insights, robust quality control, and the engineering expertise to solve complex production challenges. Conversely, choosing the wrong supplier can lead to delayed launches, budget overruns, and compromised product integrity. This article will guide you through the critical considerations for selecting a manufacturer, helping you understand what defines quality components, the materials used, how precision is achieved, and ultimately, how to identify a partner aligned with your project's unique needs.

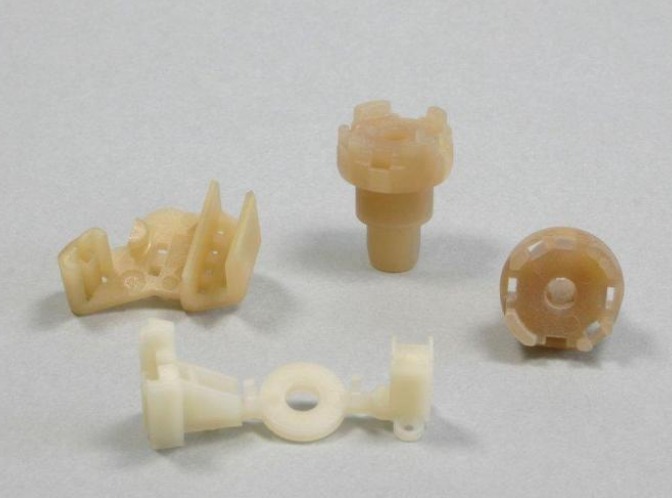

What Defines Injection Moulding Components?

Injection moulding components are parts manufactured by injecting molten material into a precision mold. Their definition hinges on three inseparable elements: the part design, the mold (or tool), and the manufacturing process. A well-designed part that cannot be efficiently molded is as much a failure as a poor design. The defining characteristics of these components are their repeatability, dimensional accuracy, and material integrity, all of which must be maintained over production runs that can number in the millions. Precision injection moulding, a subset of this field, pushes these requirements further. It is defined by part size tolerances at the 0.001 mm level and requires specific conditions: injection pressure over 25 MPa, injection speed ≥300 mm/s, and mold temperature control within ±1°C . This level of precision is essential for parts in connectors, medical devices, and automotive sensors where a micron can mean the difference between function and failure.

Key Materials Used in Injection Moulding

Material selection is the first major decision point in any project and fundamentally dictates part performance, cost, and manufacturability. Materials fall into two broad categories: commodity plastics for high-volume applications and high-performance plastics for demanding environments. The table below compares several critical high-performance polymers used in advanced applications.

| Material | Key Properties & Temperature Resistance | Typical Applications | Critical Design Consideration |

|---|---|---|---|

| PEEK | Exceptional chemical/thermal resistance (HDT 160°C). High strength & modulus . | Aerospace brackets, medical implants, pump components. | Poor flowability; requires uniform wall thickness (≥2mm) and gentle transitions to avoid voids . |

| PEI (Ultem®) | High flame retardancy (UL 94 V-0), good thermal stability (Tg 217°C) . | Medical device housings, high-temperature electrical connectors. | Hygroscopic; must be thoroughly dried before processing to prevent surface defects . |

| LCP | Excellent flow, very low warpage, ideal for thin walls. | Micro-electronic connectors, precision electrical components. | Fast solidification; requires optimized gate placement to avoid weld lines . |

| PPS | Outstanding chemical resistance and dimensional stability (HDT ~220°C) . | Sensors, battery housings, under-hood automotive parts. | Rapid crystallization; uniform cooling is critical to prevent warpage . |

| ABS | Good impact strength, rigidity, and surface finish. A versatile commodity plastic. | Automotive interiors, consumer electronics housings, toys. | Prone to warping with uneven wall thickness; requires careful mold cooling design. |

For example, a manufacturer producing a connector for an automotive sensor might recommend PPS for its chemical resistance against fuels and oils, while also advising on gate design to manage its rapid cooling characteristics . This level of material-specific guidance is a hallmark of a knowledgeable supplier.

How Do Manufacturers Ensure Precision Tolerances?

Achieving and holding tight tolerances is where a manufacturer's technical prowess becomes most visible. It is a holistic endeavor that begins with design and extends through every stage of production.

The Foundation: Design for Manufacturing (DfM)

The pursuit of precision starts long before metal is cut for a mold. A competent manufacturer will conduct a thorough DfM analysis, identifying potential issues related to wall thickness uniformity, draft angles, boss design, and rib geometry. For instance, they will insist on uniform wall thickness to ensure consistent cooling and shrinkage, preventing warpage and sink marks. They may recommend that the thickness of a reinforcing rib be no more than 60% of the adjacent wall to avoid surface defects . This collaborative design review is the most cost-effective step for preventing tolerance stack-up.

Tooling: The Heart of Precision

The mold is the physical embodiment of the part's tolerance blueprint. A manufacturer's toolmaking capability directly determines what is achievable.

- Mold Material and Construction: Precision molds are typically made from hardened steels (e.g., HRC52) and often incorporate complex systems of cooling channels, ejector pins, and venting .

- Advanced Machining: Leading manufacturers utilize 5-axis CNC machining centers and high-precision EDM (Electrical Discharge Machining) to create mold features with micron-level accuracy .

- Process Control: During production, maintaining tolerance requires controlling key variables. This involves sophisticated injection molding machines—often all-electric for their repeatability—that precisely manage injection pressure, speed, temperature, and cooling time. Some top-tier manufacturers embed temperature and pressure sensors directly within the mold for real-time, closed-loop process control .

Measurement and Validation

Precision must be verified. Advanced manufacturers are equipped with metrology labs featuring Coordinate Measuring Machines (CMMs), optical comparators, and 3D scanners. Regular First Article Inspection (FAI) and Statistical Process Control (SPC) are used to monitor production runs and ensure every batch of injection moulding components remains within the defined tolerance window .

Surface Finishing Options for Moulded Parts

The surface finish of a component affects its appearance, feel, and function. Manufacturers offer a range of options, from the texture imparted by the mold itself to secondary post-processing operations.

- As-Molded Finishes (SPI Standards): The simplest finish comes directly from the mold surface. The SPI (Plastics Industry Association) mold finish scale provides a standard, ranging from glossy (SPI A-1) to coarse matte (SPI D-3). The choice influences both aesthetics and part release from the mold.

- Secondary Finishing Operations:

- Painting and Coating: Provides color, texture, and additional protection. A critical pre-treatment for many plastics, especially polyolefins like PP, is surface activation. Advanced techniques like plasma treatment are increasingly replacing traditional flame treatment. Plasma safely increases the surface energy of a plastic bumper from ~35 mN/m to over 60 mN/m, ensuring paint adhesion is improved by 30-50% without the risk of thermal damage .

- Texture and Printing: Techniques like pad printing, hot stamping, and laser etching add logos, labels, or decorative textures.

- Plating (Chroming): Provides a metallic, conductive, or wear-resistant surface, commonly used for automotive emblems and plumbing fixtures.

Common Defects and How to Prevent Them

Understanding common defects empowers you to evaluate a manufacturer's problem-solving skills. Defects generally stem from design, tooling, material, or process issues. The table below summarizes key defects and their primary countermeasures.

| Defect | Description & Impact | Primary Prevention Strategy |

|---|---|---|

| Warping | Distorted part shape due to uneven cooling or shrinkage. | Ensure uniform wall thickness and optimize cooling channel design in the mold . |

| Sink Marks | Surface depressions over thick sections or ribs. | Design ribs at ≤60% of nominal wall thickness and ensure adequate packing pressure . |

| Short Shots | Incomplete filling of the mold cavity. | Ensure proper wall thickness (typically >0.8mm), optimize gate location, and adjust process parameters (pressure, temperature) . |

| Flash | Thin layer of plastic leaking into mold parting lines. | Ensure adequate machine clamp force and proper mold maintenance to keep parting surfaces sealed . |

| Weld/Knit Lines | Visible lines where molten plastic flows meet. | Optimize gate placement and process temperature to ensure flows merge properly . |

A top manufacturer doesn't just react to defects; they proactively prevent them. They use molding simulation software (like Moldflow) during the design phase to predict filling patterns, cooling, and potential warpage, allowing for corrections before the mold is built . Their process engineers are trained to understand the complex interplay between variables, allowing them to fine-tune the process for optimal results.

Cost Drivers in Injection Moulding Production

A clear understanding of cost drivers enables better budget planning and value-focused negotiations with a manufacturer. The costs break down into non-recurring and recurring expenses.

Non-Recurring Engineering (NRE) / Tooling Costs

This is the upfront investment in design, prototyping, and mold fabrication. It is influenced by:

- Part Complexity: Size, number of undercuts, required tolerances, and surface finish.

- Mold Material and Construction: Multi-cavity molds, use of hardened steels, and complex actions (slides, lifters) increase cost.

- Manufacturer's Engineering Input: A partner who invests in thorough DfM analysis may have a higher initial engineering fee but can significantly reduce total project cost by avoiding costly mold reworks.

Recurring / Per-Part Costs

This is the cost of each produced piece, driven by:

- Material: The type and volume of plastic used.

- Production Volume: Higher volumes typically reduce the per-part cost due to amortized tooling and setup.

- Cycle Time: The time to produce one part. An optimized cycle, achieved through efficient cooling and automation, lowers cost.

- Secondary Operations: Any required finishing, assembly, or packaging.

- Overhead and Margin: The manufacturer's operational efficiency.

It's crucial to look beyond unit price. A comprehensive cost management strategy considers total cost of ownership, including scrap rates, delivery reliability, and quality consistency. As noted in industry analyses, inefficiencies like high scrap rates, unplanned machine downtime, and labor-intensive processes are major hidden cost drivers that a proficient manufacturer actively manages .

How to Select the Right Manufacturer for Your Project

Choosing a partner is a multi-faceted evaluation that should move beyond simple price comparison. A structured assessment framework is essential.

Phase 1: Define Your Requirements and Create a Shortlist

Begin with a clear internal brief covering part specifications, volumes, timeline, and budget. Use industry directories, trade associations, and referrals to create a list of potential suppliers. Modern evaluations, like those conducted by industry groups, score manufacturers across multiple dimensions: technical capability (weight ~35%), service capacity (~25%), integrity (~20%), and cost-effectiveness (~20%) .

Phase 2: In-Depth Technical and Capability Assessment

This is the core of the selection process.

- Technical Expertise and Equipment: Inquire about their experience with your specific material (e.g., PEEK, LCP) and industry (medical, automotive). Assess their machine portfolio—do they have the clamp tonnage, platen size, and precision (e.g., all-electric machines) your part requires? Ask about auxiliary equipment like clean rooms for medical molding or robotic automation.

- Quality Systems and Certifications: Require proof of quality management system certification (e.g., ISO 9001, IATF 16949 for automotive). Investigate their measurement equipment (CMMs, etc.) and their quality control processes (SPC, FAI, OQC).

- Prototyping and Development Process: A strong partner offers prototyping services (which may use 3D printing or soft tooling) and has a formalized DfM review process. This stage reveals their engineering collaboration style.

- Supply Chain and Project Management: Evaluate their communication processes, project management tools, and their ability to provide transparent updates on mold progress and production schedules.

Phase 3: Due Diligence and Final Decision

- Request References and Samples: Speak to existing clients, especially those with similar projects. Request physical samples to assess quality firsthand.

- Conduct a Site Audit (if possible): A visit reveals the state of their facilities, organizational culture, and operational discipline.

- Evaluate Commercial Terms and Culture Fit: Finally, analyze the commercial proposal in detail. The goal is to find a manufacturer whose capabilities align with your needs and whose company culture fosters a collaborative, transparent, and long-term partnership.

Conclusion

Selecting the right injection moulding components manufacturer is a critical, multi-stage decision that balances technical capability, quality assurance, cost, and partnership potential. By understanding the core principles of injection moulding—from material science and precision engineering to defect prevention and cost structures—you empower yourself to ask the right questions and make an informed choice. The ideal manufacturer is not just a vendor but a technical collaborator invested in your product's success. They bring expertise that transforms a good design into a manufacturable, reliable, and cost-effective component. Invest the time in a thorough selection process; the right partnership will pay dividends in product quality, innovation speed, and supply chain resilience for years to come.

Frequently Asked Questions (FAQ)

How do I determine if a manufacturer has experience with high-performance plastics like PEEK or PEI?

Ask for specific case studies or sample parts they have produced with these materials. Inquire about their material handling procedures (e.g., specialized drying ovens) and if their molding machines and screws/barrels are configured for high-temperature processing, which is essential for materials like PEI that process near 340°C .

What are the key quality documents I should expect from an injection moulding manufacturer?

You should receive a First Article Inspection Report (FAIR) with full dimensional data, Material Certifications (C of C) for each batch, and Statistical Process Control (SPC) charts for critical dimensions during production runs. These documents are standard deliverables from a manufacturer with a mature quality system .

What is a reasonable tolerance to expect for a standard plastic injection moulded part?

For a typical part over 25mm in size, ±0.15 mm is a common commercial tolerance. Precision tolerances can reach ±0.025 mm or tighter, but this depends heavily on part geometry, material (amorphous vs. semi-crystalline), and requires specialized equipment and processes, which increases cost .

How can I reduce the tooling cost for a new injection moulding project?

Engage with the manufacturer's engineering team early for Design for Manufacturing (DfM) feedback. Simplifying geometry, minimizing undercuts, and specifying a standard surface finish can significantly reduce mold complexity and cost. Also, consider if a multi-cavity mold is necessary from the start or if a single-cavity tool is sufficient for initial volumes.

Contact Yigu Technology for Custom Manufacturing.

Are you looking for a manufacturing partner who combines deep technical expertise with a commitment to quality and collaboration? At Yigu Technology, we specialize in the precision manufacturing of complex injection moulding components. Our team of engineers is proficient in working with a wide range of materials, from commodity polymers to advanced high-performance plastics, and we employ state-of-the-art equipment and rigorous process controls to ensure your specifications are met consistently.

We invite you to discuss your next project with us. From the initial DfM consultation through to high-volume production, we are dedicated to being an extension of your team and helping bring your designs to life with reliability and precision.

Contact us today to start a conversation about your custom manufacturing needs.