DOE Injection Molding, or Design of Experiments, is a systematic, data-driven methodology used to optimize the plastic injection molding process. Moving beyond traditional trial-and-error or one-factor-at-a-time (OFAT) approaches, DOE allows engineers to efficiently discover the relationships between multiple input variables (like temperature, pressure, and speed) and key output results (like part dimensions, strength, and cycle time). This guide is crafted for process engineers, quality managers, and manufacturing leaders who seek to master scientific molding principles. We will explore how DOE establishes a robust, repeatable process window, minimizes defects, and maximizes efficiency, transforming molding from an art into a predictable engineering discipline.

What Is DOE Injection Molding?

DOE Injection Molding is the application of statistical Design of Experiments principles to the injection molding process. It is a structured approach for planning, conducting, analyzing, and interpreting controlled tests to evaluate the factors that influence output quality. In practice, it involves running a series of carefully designed molding shots where specific machine parameters are deliberately varied according to a predefined matrix. The resulting parts are measured, and the data is statistically analyzed to identify the optimal process settings that produce parts within specification, with minimal variation, and at the lowest possible cost.

The core objective is to move from a single "sweet spot" setting (which is fragile to material or environmental changes) to a robust process window—a range of settings where part quality remains acceptable. This is the foundation of scientific molding and a requirement for industries like automotive and medical.

How Does Design of Experiments Optimize Process Windows?

Traditional setup often finds a single setting that works. DOE maps the entire landscape of possibilities to find the most stable region.

- Defining the Objective: The process starts with a clear goal: "Minimize warpage," "Eliminate sink marks," "Reduce cycle time by 15%," or "Achieve consistent part weight."

- Selecting Factors and Levels: Key input variables (factors) are chosen (e.g., melt temperature, injection speed, pack pressure, cooling time). For each factor, a high and low value (level) is set, representing a realistic operating range.

- Running the Experimental Matrix: Instead of changing one factor at a time, a DOE matrix (like a Full Factorial or Fractional Factorial design) dictates which combination of high/low settings to run for each shot. This is efficient; a 5-factor DOE can require as few as 16 shots to gather meaningful data.

- Measuring Responses: For each shot, critical responses are measured: part dimensions, weight, shrinkage, warpage, or the presence of defects.

- Statistical Analysis & Modeling: Software analyzes the data to create a mathematical model of the process. It identifies which factors have the most significant effect (main effects) and if factors interact with each other (interactions).

- Finding the Optimal Window: The analysis reveals the combination of factor settings that optimize all responses simultaneously. This region is the robust process window—where natural process variation is least likely to cause defects.

Which Parameters Should Be Varied First?

While every part is unique, the focus should be on the four critical plastic variables that most directly control part quality. Starting here provides the highest return on investment.

| Process Parameter (Factor) | What It Controls | Typical Range to Explore | Primary Impact on Part |

|---|---|---|---|

| Melt Temperature | Polymer viscosity and flowability. | Manufacturer's recommended range ± 15°C. | Surface finish, strength, presence of flow lines or burns. |

| Injection Speed | How fast the mold cavity fills. | From slow fill (visual) to machine maximum. | Weld line strength, orientation, and risk of jetting or air traps. |

| Packing Pressure | Compensates for volumetric shrinkage after fill. | 50% to 80% of injection pressure. | Part weight, dimensional stability, and sink marks. |

| Packing Time | Duration the packing pressure is applied. | From short (part underweight) until part weight stabilizes. | Part weight and dimensions; gates must be sealed. |

Secondary factors to consider in follow-up DOEs include: Coolant Temperature, Back Pressure, and Mold Temperature. A key tenet of scientific molding is to establish these four primary variables before adjusting secondary ones.

Professional Insight: The first step in any DOE should be a Viscosity Curve Study. This simple, one-factor DOE involves injecting at several different speeds while holding other variables constant and recording the fill pressure. The resulting curve shows the material's viscosity profile. It identifies the injection speed where viscosity is lowest (easiest to process) and confirms the machine is capable of consistent, repeatable fills—a prerequisite for any further experimentation.

What Software Tools Support DOE Analysis?

Modern DOE relies on specialized software to design experiments and decode complex data.

- Molding Machine Software: Many modern presses have DOE modules built into their controls (e.g., Engel's iQ weight control, Sumitomo's V-Line). They can automatically set up and run the shot sequence, directly logging machine data.

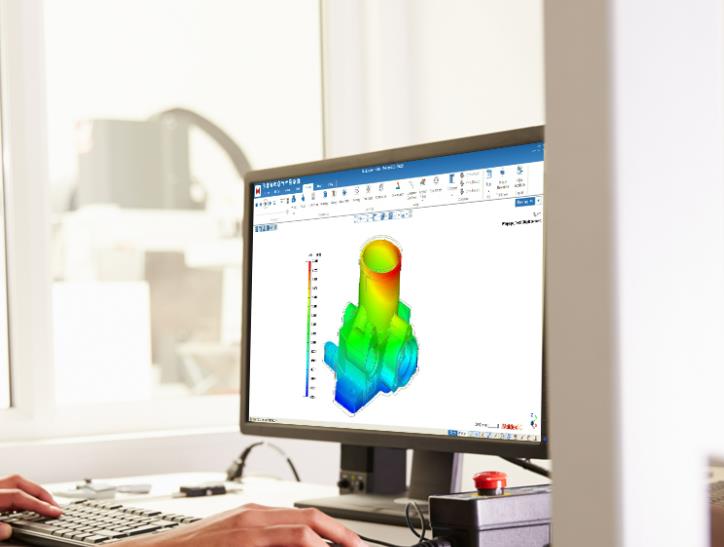

- Statistical Software: Packages like Minitab, JMP, and Design-Expert are industry standards. They guide the design creation (e.g., choosing a Taguchi or Response Surface design), perform Analysis of Variance (ANOVA), and generate interaction plots and optimization graphs.

- Integrated Scientific Molding Systems: Platforms like RJG's eDART or Moldflow can be used to design experiments, collect real-time cavity pressure and temperature data during the DOE runs, and analyze the results. This links machine parameters directly to what's happening inside the mold cavity.

The output is not just a set of numbers, but visual tools like Contour Plots that show the "safe operating region" for two variables at a time, making the optimal window clear and actionable for technicians.

How Can Shrinkage and Warpage Be Minimized?

Shrinkage (uniform size reduction) and warpage (non-uniform distortion) are the top causes of dimensional failure. DOE is the most effective tool to combat them.

- Understanding the Cause: Shrinkage is primarily a function of material crystallinity and thermal history. Warpage is caused by differential shrinkage—different areas of the part cool and shrink at different rates due to uneven wall thickness, cooling, or molecular orientation.

- DOE Strategy for Minimization:

- Factors: Focus on Mold Temperature, Melt Temperature, Packing Pressure/Time, and Cooling Time. These directly control cooling rate and material packing.

- Responses: Measure critical dimensions at multiple locations on the part and calculate shrinkage. Use a flatness gauge or CMM to measure warpage (out-of-plane distortion).

- Analysis: The software will identify which factor most influences shrinkage uniformity. Often, a higher mold temperature promotes more uniform cooling, reducing internal stresses that cause warpage. The DOE will find the balance where overall shrinkage is predictable and differential shrinkage is minimized.

Case Studies: Cycle-Time Reduction and Defect Elimination

Case Study 1: Eliminating Sink Marks on a Thick-Ribbed Housing

A molder was producing an ABS electronic housing with prominent sink marks over reinforcing ribs, leading to a 25% scrap rate. Aesthetic standards were strict.

- DOE Approach: A 2-level, 4-factor DOE was run, varying Melt Temp, Injection Speed, Pack Pressure, and Pack Time.

- Analysis & Finding: The statistical analysis revealed a strong interaction between Pack Pressure and Pack Time. The traditional high-pressure/short-time approach was ineffective. The DOE model showed that a moderate pack pressure with a longer pack time allowed the material to pack out the thick rib without creating excessive stress.

- Result: The optimized settings eliminated the sink marks, reduced the scrap rate to under 1%, and only increased the cycle time by 1.5 seconds—a net gain in quality and throughput.

Case Study 2: Reducing Cycle Time for a Polypropylene Container

A high-volume packaging plant needed to reduce the 12-second cycle time for a food container to meet rising demand without buying new machines.

- DOE Approach: A DOE focused on Cooling Efficiency. Factors included Coolant Temperature, Cooling Time, and Ejection Temperature (measured via infrared).

- Analysis & Finding: The analysis created a model predicting part temperature at ejection. It identified that the original cooling time was longer than necessary for the chosen coolant temperature. More importantly, it showed that a slight increase in coolant temperature actually led to more efficient heat transfer from the part, reducing the temperature gradient and allowing safe ejection earlier.

- Result: By implementing the DOE-optimized settings, the molder achieved a 9.5-second cycle time—a 21% reduction. This increased output by over 1,000 parts per machine per day without compromising part quality or dimensions.

Conclusion

DOE Injection Molding is not merely a troubleshooting tool; it is a proactive strategy for manufacturing excellence. By replacing intuition with empirical data and statistical analysis, it allows engineers to unlock the true potential of their molds, materials, and machines. The result is a robust, documented process that yields higher quality parts, minimizes waste, reduces costs, and provides a deep understanding of process cause-and-effect. In an industry driven by margins and quality standards, mastering DOE is what separates leading scientific molding practitioners from the rest, ensuring consistent, efficient, and profitable production.

FAQ

What is the difference between DOE and Scientific Molding?

Scientific Molding is the overarching philosophy of using data, measurements, and the laws of plastics processing to establish a repeatable molding process. DOE (Design of Experiments) is a specific, powerful tool within the Scientific Molding toolkit used to systematically optimize that process. Scientific Molding defines what to control (the 4 critical variables), and DOE defines how to find the best settings for them.

How many shots or parts are needed for a typical DOE?

It depends on the design. A simple screening DOE with 4 factors might use an 8-run fractional factorial design, requiring 8 shots (plus repeats for statistical power). A more comprehensive optimization DOE might use 16 to 32 runs. The key is that DOE is vastly more efficient than one-factor-at-a-time testing, which for 4 factors could require hundreds of shots to get the same information.

Can DOE be used for new mold qualification?

Absolutely. In fact, it is the ideal method for Process Qualification (PQ). Running a DOE during mold sampling establishes the process window and provides documented evidence that the process is capable and robust before full production begins. This data is essential for validation reports in regulated industries.

What if my DOE results show that the mold design is the problem?

This is a common and valuable outcome. DOE may reveal that no combination of machine settings can achieve a dimension or eliminate a defect because the root cause is mold design (e.g., poor gate location, inadequate cooling, or non-uniform wall thickness). This objective data is crucial to justify and guide necessary mold modifications before investing in mass production.

Do I need a statistician to run a DOE for injection molding?

While statistical knowledge is beneficial, it is not a barrier to entry. Modern software like Minitab or JMP provides user-friendly wizards to set up standard designs. Many molding consultants and machine software packages offer templates. The core requirement is a disciplined approach to running the shots exactly as designed and meticulously measuring the responses. Training in basic DOE principles for engineers is highly recommended and yields a high return.

Contact Yigu Technology for Custom Manufacturing.

Achieve manufacturing excellence with Yigu Technology's data-driven approach. Our expertise in Scientific Molding and DOE Injection Molding ensures your projects are launched with optimized, robust, and fully documented processes. We utilize advanced molding machines with integrated DOE capabilities and statistical analysis software to systematically eliminate defects, reduce cycle times, and guarantee consistent part quality. From initial viscosity curve analysis to full process validation, we engineer reliability into every production run. Contact Yigu Technology today to discuss how our engineering-led approach can enhance the quality, efficiency, and profitability of your injection molded components.