Introduction

The Significance of Plastic Injection Molding in the Medical Field

In the rapidly evolving medical industry, plastic injection molding has emerged as a cornerstone manufacturing process. It plays a pivotal role in producing a vast array of medical parts, from simple syringe components to complex implantable devices. The demand for high - precision, reliable, and cost - effective medical parts has driven the continuous innovation and improvement of plastic injection molding technology.

Plastic injection molding allows for the mass production of medical components with tight tolerances. For example, in the production of insulin pens, the plastic parts need to be precisely manufactured to ensure accurate dosage delivery. A slight deviation in the size of the piston or the housing can lead to incorrect insulin dispensing, which can have serious consequences for patients. According to industry statistics, over 80% of disposable medical devices, such as syringes, catheters, and IV connectors, are made through plastic injection molding. This high percentage not only reflects the prevalence of the process but also its importance in meeting the large - scale demand for these essential medical products.

The Basics of Plastic Injection Molding for Medical Parts

Process Breakdown

- Raw Material Preparation: The first step is to select the appropriate medical - grade plastic materials. These materials must meet strict biocompatibility, chemical resistance, and mechanical property requirements. For example, polypropylene (PP) is often used for its good chemical resistance and is suitable for applications like syringe barrels. Polycarbonate (PC) is chosen for its high strength and transparency, making it ideal for components in medical devices where visibility is important. The plastic materials usually come in pellet form and may need to be dried before processing to remove any moisture. Moisture in the plastic can cause defects such as bubbles or poor surface finish in the final product.

- Heating and Melting: The dried plastic pellets are fed into the hopper of an injection molding machine. From there, they enter the heating barrel. The barrel is equipped with heating elements that raise the temperature of the plastic to its melting point. As the plastic moves through the barrel, it is also agitated by a rotating screw. This agitation helps to ensure uniform melting and mixing of the plastic. For instance, if a colorant or additive is added to the plastic for specific functionality (such as a radiopaque additive for better visibility in medical imaging), the rotation of the screw aids in evenly dispersing it throughout the molten plastic.

- Injection: Once the plastic is fully melted and in a homogeneous, viscous state, the screw moves forward, forcing the molten plastic under high pressure into the closed mold cavity. The injection pressure is carefully controlled to ensure that the plastic fills every part of the mold cavity completely and accurately. In the production of a complex medical component with fine details, such as a microfluidic chip, precise injection pressure is crucial to replicate the intricate channels and structures within the mold.

- Cooling and Solidification: After the mold cavity is filled with molten plastic, the plastic needs to cool down and solidify to take the shape of the mold. The mold is usually connected to a cooling system, which can be water - cooled or air - cooled. The cooling rate affects the quality of the final product. A too - fast cooling rate can lead to internal stresses in the plastic part, which may cause warping or cracking. Conversely, a slow cooling rate can increase the production cycle time. For example, in the production of a large - scale medical housing, a well - designed cooling system is necessary to ensure uniform cooling and prevent deformation.

- Mold Opening and Part Ejection: Once the plastic part has solidified sufficiently, the mold opens. Ejector pins or other ejection mechanisms push the solid plastic part out of the mold cavity. Care must be taken during this step to ensure that the part is not damaged during ejection. In some cases, especially for parts with complex geometries or undercuts, more sophisticated ejection systems may be required.

- Post - processing: After ejection, the plastic part may undergo post - processing steps. This can include trimming any excess material (such as flash or runners), polishing the surface for better aesthetics or functionality, and performing secondary operations like assembly with other components. For medical parts, additional sterilization processes may also be part of the post - processing. Sterilization methods can include gamma irradiation, ethylene oxide sterilization, or autoclaving, depending on the material and the end - use requirements of the medical part.

Key Equipment and Machinery

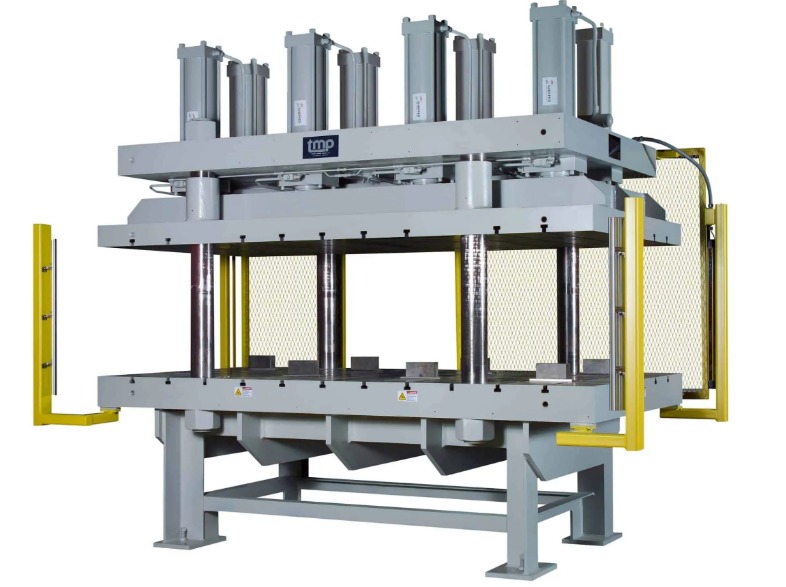

- Injection Molding Machine: The injection molding machine is the heart of the plastic injection molding process. It consists of several key components, including the injection unit, the clamping unit, and the control system. The injection unit is responsible for melting the plastic and injecting it into the mold. It includes the hopper, heating barrel, and screw. The clamping unit holds the mold closed during injection and provides the necessary force to prevent the mold from opening due to the high injection pressure. The control system allows operators to set and monitor various parameters such as temperature, pressure, injection speed, and cooling time. Injection molding machines come in different sizes and capacities, with clamping forces ranging from a few tons to thousands of tons, depending on the size and complexity of the medical parts being produced.

- Molds: Molds are custom - designed tools that determine the shape of the final plastic part. For medical parts, molds need to be extremely precise, often with tolerances in the micron range. They are typically made from high - quality steel or aluminum alloys for durability and to maintain their dimensional accuracy over a large number of production cycles. Molds can be single - cavity (producing one part per cycle) or multi - cavity (producing multiple identical parts per cycle). The design of the mold includes considerations for the flow of the molten plastic (gating system), the removal of air from the mold cavity (venting system), and the cooling of the plastic (cooling channels). For example, in the production of a high - volume medical syringe, a multi - cavity mold can significantly increase production efficiency.

Key Considerations in Plastic Injection Molding for Medical Parts

Material Selection

Material selection is of utmost importance in plastic injection molding for medical parts. The materials used must meet strict standards to ensure the safety and effectiveness of the medical devices.

- Biocompatibility: This is a fundamental requirement. The plastic material should not cause any adverse reactions when in contact with the human body, whether it is a short - term exposure, such as in the case of a syringe, or long - term implantation, like a joint replacement component. For example, silicone is widely used in medical applications such as catheters and breast implants due to its excellent biocompatibility. It can be in contact with body fluids and tissues without triggering significant immune responses.

- Chemical Resistance: Medical parts may be exposed to a variety of chemicals, including disinfectants, cleaning agents, and medications. Materials need to be resistant to these chemicals to maintain their integrity and functionality. Polypropylene (PP) is often chosen for its good chemical resistance. It can withstand common disinfectants like alcohol - based solutions, making it suitable for components in medical devices that require regular cleaning and disinfection.

- Sterilization Compatibility: Since medical parts must be sterilized before use, the materials should be able to withstand the chosen sterilization method. For instance, polyetheretherketone (PEEK) can resist gamma radiation and high - pressure steam sterilization (autoclaving), which are common sterilization techniques. This makes PEEK a popular choice for surgical instruments and implantable devices.

Some of the commonly used materials in medical plastic injection molding and their selection reasons are as follows:

| Material | Advantages for Medical Use | Common Applications |

| Polycarbonate (PC) | High impact resistance, transparency, and dimensional stability. It can be easily sterilized and is suitable for applications where visibility and durability are important. | Medical instrument housings, optical components in medical devices. |

| Polyethylene (PE) | Good flexibility, chemical resistance, and low cost. It has excellent non - reactivity with many substances, making it safe for use in contact with body fluids. | Blood bags, tubing, and some disposable medical products. |

| Polypropylene (PP) | High chemical resistance, good mechanical properties, and can be sterilized by various methods. It is also relatively lightweight. | Syringe barrels, medical containers, and some surgical drapes. |

| Polyetherimide (PEI) | High - temperature resistance, good mechanical strength, and dimensional stability. It has excellent biocompatibility and can be sterilized repeatedly. | Components in high - end medical equipment, such as parts in surgical robots that need to withstand high - stress and high - temperature sterilization processes. |

Design for Manufacturability

The design of medical parts has a profound impact on the plastic injection molding process and the quality of the final product.

- Wall Thickness Uniformity: Maintaining a consistent wall thickness throughout the part is crucial. Uneven wall thickness can lead to issues such as warping, sink marks, and inconsistent cooling. For example, in the design of a medical device housing, if one section has a much thicker wall than others, during the cooling process, the thicker section will cool more slowly, causing internal stresses that can result in the housing warping out of shape. This not only affects the aesthetics but also can impact the functionality, such as preventing proper assembly of internal components. A general rule of thumb is to keep the wall thickness variation within ± 10% of the nominal thickness for optimal results.

- Draft Angles: Draft angles, also known as 脱模斜度,are essential for easy removal of the molded part from the mold. Without proper draft angles, the part may get stuck in the mold during ejection, leading to damage or deformation. In the case of a small, intricate medical component like a micro - fluidic chip, a draft angle of at least 0.5 - 1 degree on vertical surfaces is recommended. This allows the part to slide smoothly out of the mold cavity as the mold opens.

- Rounded Corners and Edges: Sharp corners and edges in the design can create stress concentration points during the injection molding process. These points are more likely to develop cracks or breakages. Rounding the corners and edges, with a minimum radius of, for example, 0.5 - 1 mm depending on the size of the part, helps to distribute the stress evenly and improve the structural integrity of the part. In a medical implant, rounded edges can also reduce the risk of tissue damage during implantation.

Quality Control and Regulatory Compliance

Quality control in plastic injection molding for medical parts is extremely rigorous due to the direct impact on patient safety.

- In - Process Quality Checks: During the injection molding process, regular quality checks are carried out. This includes monitoring the injection pressure, temperature, and cycle time. For example, if the injection pressure drops below the set value, it may indicate a problem with the injection system or the flow of the molten plastic, which could result in an incomplete or defective part. Sensors are often used to continuously monitor these parameters, and any deviation from the pre - set limits can trigger an alarm for operators to take corrective actions.

- Final Product Inspection: Every finished medical part undergoes a comprehensive inspection. This includes dimensional inspection using precision measuring tools such as coordinate measuring machines (CMMs) to ensure that the part meets the design specifications. Visual inspection is also crucial to detect any surface defects like scratches, bubbles, or discoloration. In addition, functional testing is performed to verify that the part functions as intended. For a syringe, this would involve testing the plunger movement for smoothness and accuracy of dosage delivery.

Medical plastic injection molding must comply with a series of strict regulations and standards:

- ISO 13485: This is an international standard for the quality management system in the medical device industry. It requires manufacturers to establish and maintain a quality management system that ensures the safety and effectiveness of medical devices. Companies that comply with ISO 13485 are better equipped to control all aspects of the production process, from design and development to production, installation, and servicing.

- FDA Regulations: In the United States, the Food and Drug Administration (FDA) has strict regulations for medical devices. Manufacturers must meet the requirements of 21 CFR Part 820, which covers aspects such as design control, document control, purchasing control, and production and process controls. For example, medical parts that are intended for use in the US market need to be properly labeled, and the manufacturing facility must pass FDA inspections.

- CE Marking: In the European Union, medical devices must bear the CE mark to indicate compliance with the relevant European Union directives. This involves meeting standards related to safety, health, and environmental protection. The CE marking process requires manufacturers to demonstrate that their products meet the essential requirements of the applicable directives through a series of conformity assessment procedures.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology deeply understands the significance of plastic injection molding for medical parts. With years of experience in the field, we have honed our expertise in several key aspects.

In terms of material selection, we are well - versed in a wide range of medical - grade plastics. We work closely with reliable material suppliers to ensure that the materials we use not only meet strict biocompatibility, chemical resistance, and sterilization compatibility requirements but also offer cost - effective solutions for our clients. Our in - house material testing capabilities enable us to verify the quality and performance of materials before production, reducing the risk of product failures.

When it comes to design, our team of experienced engineers can provide comprehensive design - for - manufacturability services. We help our clients optimize their medical part designs, taking into account factors such as wall thickness uniformity, draft angles, and rounded corners. By doing so, we can enhance the manufacturability of the parts, improve production efficiency, and reduce production costs.

In summary, Yigu Technology is committed to providing high - quality plastic injection molding solutions for medical parts, leveraging our expertise in materials, design, and quality control to meet the diverse needs of the medical industry.

FAQ

What are the common materials used in plastic injection molding for medical parts?

Common materials include polycarbonate (PC) known for its high impact resistance and transparency, suitable for instrument housings; polyethylene (PE) with good flexibility and chemical resistance, often used in blood bags; polypropylene (PP) having high chemical resistance and being suitable for syringe barrels; and polyetherimide (PEI) with high - temperature resistance and excellent biocompatibility, used in high - end medical equipment components. Each material's unique properties make it suitable for specific medical applications based on requirements like biocompatibility, chemical resistance, and sterilization compatibility.

How to ensure the quality of plastic injection - molded medical parts?

Quality can be ensured through several means. First, conduct strict material testing before production to verify its compliance with medical - grade standards in terms of biocompatibility, chemical resistance, etc. During the injection molding process, closely monitor parameters such as injection pressure, temperature, and cycle time. For example, use sensors to detect any deviation promptly. After production, perform comprehensive final product inspections, including dimensional inspection with precision tools like CMMs, visual checks for surface defects, and functional testing to ensure the part functions as intended.

What are the main differences between plastic injection molding for medical parts and other industries?

In terms of materials, medical parts require biocompatible plastics that can meet strict safety standards, while other industries may focus more on cost - effectiveness or general - purpose properties. Quality standards for medical parts are extremely high due to patient safety concerns, involving rigorous in - process and final inspections, as well as compliance with international regulations like ISO 13485 and FDA regulations. Design requirements for medical parts often demand higher precision, with considerations for factors like wall thickness uniformity within a very narrow tolerance range, specific draft angles for easy mold ejection, and rounded corners to prevent stress concentration, which may be less critical in some other industries.