Introduction

What is a Plastic Injection Press?

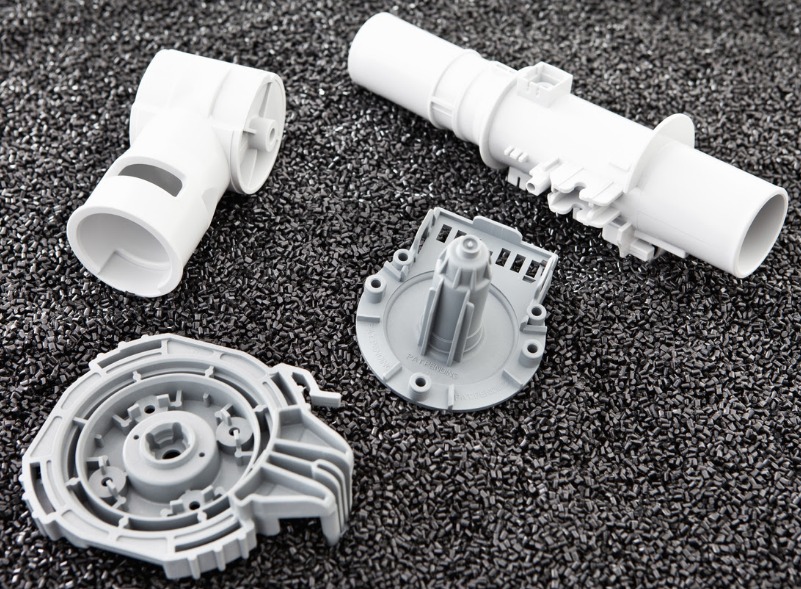

A Plastic Injection Press, also known as an injection molding machine, is a crucial piece of equipment in the plastic manufacturing industry. It works by melting plastic pellets and injecting the molten plastic into a mold cavity under high pressure. Once the plastic cools and solidifies within the mold, it takes on the shape of the mold cavity, creating a wide variety of plastic products.

These products can range from small and intricate components like electronic device parts to large and complex items such as automotive bumpers. In fact, plastic injection presses are so versatile that they are used in almost every industry that involves plastic products, including consumer goods, medical, aerospace, and more. Their importance lies in their ability to produce high - volume, high - precision plastic parts with relatively low labor costs per unit, making plastic products affordable and accessible to a wide range of consumers.

Why Consider a Used Plastic Injection Press?

Cost - effectiveness: One of the most significant reasons to consider a used plastic injection press is the cost savings. New plastic injection presses can be extremely expensive, especially for large - scale, high - precision models. For example, a brand - new, high - capacity injection press from a well - known manufacturer might cost hundreds of thousands of dollars. In contrast, a used press of the same or similar specifications can be purchased for a fraction of the price, sometimes as low as 30 - 50% of the new price. This cost advantage allows small and medium - sized enterprises (SMEs) to enter the plastic manufacturing market or expand their production capabilities without a massive initial investment.

Quick Put into production: Buying a used plastic injection press can also lead to a faster start - up time. Since the machine is already in existence and has been used before, there is no need to wait for the manufacturing and delivery process that comes with a new machine. In some cases, a used press can be purchased, transported, and set up within a matter of weeks, compared to the months it might take to order and receive a new one. This quick turnaround time means that businesses can start producing and generating revenue sooner.

Key Factors to Consider When Buying a Used Plastic Injection Press

Machine Condition

Inspection of Mechanical Parts

When assessing a used plastic injection press, a thorough inspection of mechanical parts is essential. The screw, for instance, is a critical component that directly impacts the plastic - melting and injection process. A worn - out screw may not be able to melt the plastic pellets evenly, leading to inconsistent product quality. Signs of excessive wear include grooves, uneven surfaces, or a reduction in the screw's diameter. The barrel, which houses the screw, should also be carefully examined. Cracks, corrosion, or significant wear in the barrel can cause plastic leakage or affect the heat - transfer efficiency during the melting process.

The clamping mechanism, responsible for holding the mold firmly during injection, is another key area. Check for any misalignment, loose connections, or wear in the toggle arms (if it's a toggle - type clamping system) or hydraulic cylinders (in a hydraulic clamping system). A malfunctioning clamping mechanism can result in mold misalignment, flash (excess plastic around the product edges), or even mold damage.

Electrical and Hydraulic Systems

The electrical system of the plastic injection press controls various functions such as motor operation, temperature regulation, and control panel functions. Look for signs of aged or damaged electrical wiring, which could pose a safety hazard and lead to unexpected equipment failures. Frayed wires, corroded connectors, or non - functioning sensors are all red flags. For example, a faulty temperature sensor may cause the machine to overheat or under - heat the plastic, ruining the production run.

The hydraulic system, which powers many of the mechanical movements like clamping and injection, needs to be leak - free. Hydraulic fluid leaks not only waste expensive fluid but can also indicate underlying problems such as damaged seals, cylinders, or hoses. Additionally, check the hydraulic pump for abnormal noises or vibrations, which could signal internal wear or a lack of proper lubrication.

Production History

Previous Usage Intensity

Knowing the previous usage intensity of the used plastic injection press is crucial for estimating its remaining lifespan. If the machine has been operating continuously for long hours, say 20 - 24 hours a day, five or six days a week for several years, it is likely to have more wear and tear compared to a machine that was used for only 8 - 10 hours a day. For example, a press that has accumulated 50,000 operating hours over a short period may have significantly more wear in its mechanical and electrical components than a similar press that reached the same number of hours over a longer time frame with more regular maintenance intervals.

Type of Products Manufactured

The type of products previously manufactured on the press can also give insights into its condition. Producing large, complex parts may have put more stress on the machine, especially on the clamping and injection systems. For instance, manufacturing automotive bumpers requires a high - clamping force and large - volume plastic injection. If the press was used for such high - stress applications, it may have more wear in the clamping mechanism and the injection unit compared to a press that was used to produce small, simple plastic components like bottle caps.

Brand and Reputation

Well - known Brands

Well - known brands in the plastic injection press market, such as Engel, Arburg, and Haitian, often come with a reputation for quality, stability, and excellent 售后服务. These brands typically invest heavily in research and development, using high - quality materials and advanced manufacturing techniques. For example, Engel injection presses are renowned for their precision and energy - efficiency, while Arburg is known for its versatility and reliability. A used press from a respected brand is more likely to have better - built components, which can withstand long - term use and require fewer repairs.

User Reviews and Industry Reputation

Reading user reviews and considering the industry reputation of the brand and the specific model can provide valuable information. Online forums, industry magazines, and professional networks can be great sources of feedback. If a particular model has a history of frequent breakdowns or poor performance, as reported by other users, it's a sign to approach it with caution. On the other hand, a model with positive reviews regarding its durability, ease of maintenance, and performance can give you more confidence in your purchase decision.

Compatibility and Specifications

Meeting Your Production Requirements

Selecting a used plastic injection press that meets your production requirements is fundamental. First, consider the required clamping force. If you plan to produce large - sized plastic products with a large surface area, you'll need a press with a higher clamping force to prevent the mold from opening during injection. For example, a product with a projected area of 100 square inches may require a clamping force of 10 - 15 tons, depending on the plastic material and the complexity of the mold.

The injection volume is another crucial factor. Calculate the volume of plastic needed for your products and ensure that the press can deliver the required shot size. If your product requires an injection volume of 500 cubic centimeters, make sure the press you're considering has an injection capacity that can meet or exceed this amount.

Compatibility with Existing Equipment

Check the compatibility of the used press with your existing molds and 辅助设备. The mounting dimensions of the press should match those of your molds to ensure a proper fit. Additionally, consider the connection and communication interfaces between the press and other equipment such as material - handling systems, robots for part removal, and temperature - control units. If the press is not compatible with your existing auxiliary equipment, you may need to invest in additional adapters or new equipment, which can increase the overall cost of acquisition and integration.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology understands the importance of cost - effective production solutions. We believe that used plastic injection presses can be a viable option for many of our clients who are looking to control costs without sacrificing too much on production capabilities. However, we also emphasize the need for careful evaluation when purchasing a used press. Our team of experts has in - depth knowledge of plastic injection processes and equipment. We are committed to providing technical support to our clients during the purchasing process. Whether it's helping them understand the technical specifications of a used press, or assessing its compatibility with their existing production lines, we are here to assist. We want our clients to make informed decisions so that they can select the right used plastic injection press that meets their production requirements and quality standards.

FAQs

1. How can I tell if a used plastic injection press is in good condition?

Inspect the mechanical parts for wear, such as the screw, barrel, and clamping mechanism. Check the electrical system for damaged wiring and malfunctioning sensors. Examine the hydraulic system for leaks and abnormal noises in the pump. Also, review the production history and maintenance records if available.

2. Are there any legal issues to consider when buying a used plastic injection press?

Yes, ensure that the seller has the legal right to sell the equipment. Get a detailed bill of sale that includes all the specifications of the press. Also, clarify any warranty or liability issues in writing to avoid potential disputes later.

3. Can I upgrade the components of a used plastic injection press?

In many cases, yes. Components like the control system, heating elements, or even the injection unit can be upgraded. However, it's important to ensure that the upgrades are compatible with the existing machine and comply with safety and industry standards. Consult with a professional or the manufacturer for the best upgrade options.