What is Prototyping Injection Molding?

Prototyping injection molding is a crucial process in product development. It is a specialized form of injection molding, a manufacturing technique widely used for creating plastic parts in large quantities. The prototyping version, however, is focused on producing early - stage models of a product, allowing product developers to test and refine their designs before full - scale production.

The process begins with the preparation of the plastic material. Granules of plastic, such as ABS, PLA, or polypropylene, are loaded into the hopper of an injection molding machine. These granules are then heated to a molten state, typically reaching temperatures between 180°C - 300°C depending on the type of plastic. For example, ABS usually melts at around 220°C - 260°C, while PLA melts at a lower temperature range of 180°C - 220°C.

Once the plastic is in a molten state, it is injected under high pressure, usually between 50 - 200 MPa, into a precisely crafted mold. The mold is designed to have a cavity in the exact shape of the desired product prototype. The high - pressure injection ensures that the molten plastic fills every detail of the mold cavity, replicating even the most intricate features. After the mold is filled, the plastic is allowed to cool and solidify. This cooling process can take anywhere from a few seconds to a couple of minutes, depending on the size and complexity of the prototype. Once solidified, the mold is opened, and the newly formed plastic prototype is ejected.

This process is highly precise. For instance, modern injection molding machines can achieve tolerances as low as ±0.05 mm, which is crucial for creating accurate product prototypes. It allows product developers to quickly turn their ideas into physical models, enabling them to conduct functional and aesthetic tests, make design adjustments, and gather valuable feedback early in the development cycle.

The Process of Prototyping Injection Molding

Step - by - Step Guide

- Plastic Material Preparation: Start by carefully selecting the appropriate plastic material for your prototype. As mentioned before, common choices include ABS, PLA, and polypropylene. These come in granular form and are loaded into the hopper of the injection molding machine. For instance, if you're creating a prototype for a consumer electronics component that requires high impact - resistance, ABS might be a top choice.

- Heating and Melting: The plastic granules are then transported through a heated barrel. Inside the barrel, a reciprocating screw plays a crucial role. It rotates, pushing the plastic forward while also generating frictional heat. The combination of external heating elements and this frictional heat raises the temperature of the plastic to its melting point. As stated earlier, the temperature can range from 180°C - 300°C depending on the plastic type. This melting process turns the solid plastic granules into a highly viscous, flowing liquid.

- Injection: Once in a molten state, the plastic is ready for injection. A high - pressure system, typically capable of exerting pressures between 50 - 200 MPa, forces the molten plastic through a nozzle and into the mold cavity. The speed of injection is also a critical factor, usually ranging from 30 - 150 mm/s. This high - pressure, high - speed injection ensures that the plastic fills every intricate detail of the mold, whether it's a small, detailed logo or a complex internal structure.

- Cooling and Solidification: After the mold is filled, the plastic needs to cool down and solidify to maintain its shape. This cooling process is facilitated by a cooling system within the mold. Water or other cooling fluids are circulated through channels in the mold to extract heat from the plastic. As the plastic cools, it gradually transitions from a liquid to a solid state. The cooling time, as previously noted, can vary from a few seconds to a couple of minutes, depending on the size and complexity of the prototype. For a small, simple plastic button, the cooling time might be as short as 5 - 10 seconds, while a larger, more complex automotive interior component could take 60 - 120 seconds.

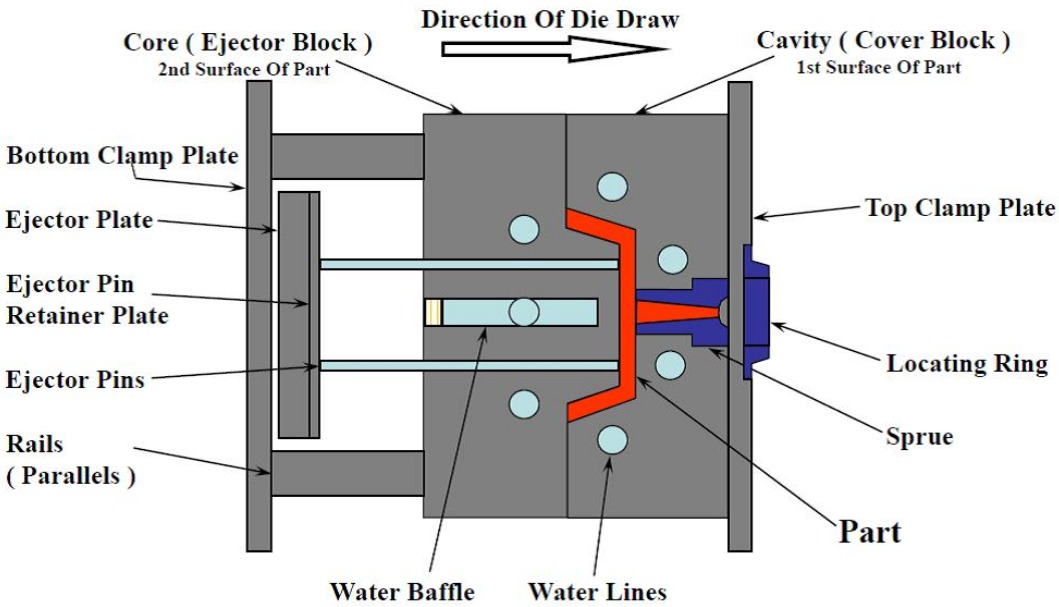

- Mold Opening and Part Ejection: Once the plastic has solidified sufficiently, the mold is opened. Most molds are designed with two halves, a stationary half and a moving half. Hydraulic or mechanical systems are used to separate these two halves. After the mold is open, the newly formed plastic prototype needs to be removed. Ejector pins, which are small rods located within the mold, are activated. These pins push the prototype out of the mold cavity, allowing it to be easily retrieved.

- Post - Processing: The prototype might require some post - processing steps. This could include removing any excess plastic, also known as flash, that has formed during the injection process. Trimming tools, such as sharp knives or specialized trimming machines, are used for this purpose. Sanding might be done to smooth out any rough surfaces, and polishing can be applied to achieve a desired aesthetic finish. In some cases, the prototype might need to be painted, plated, or coated to meet specific design requirements.

Key Equipment Involved

- Injection Molding Machine: This is the central piece of equipment in the prototyping injection molding process. It consists of several key components. The hopper is where the plastic raw material is loaded. The heating barrel, as described earlier, is responsible for melting the plastic. The injection unit, which includes the reciprocating screw and the high - pressure system, is crucial for injecting the molten plastic into the mold. The clamping unit is equally important. It holds the mold closed during the injection and cooling phases, ensuring that the high - pressure plastic doesn't force the mold open. Injection molding machines come in different sizes and capacities, with clamping forces ranging from a few tons to over a thousand tons. For prototyping, smaller machines with clamping forces in the range of 10 - 100 tons are often sufficient.

- Mold: The mold is a precision - crafted tool that determines the shape of the prototype. It is typically made of high - strength steel or aluminum. Molds can be single - cavity, meaning they produce one prototype per cycle, or multi - cavity, which can produce multiple prototypes at once. The mold has a cavity that is an exact negative of the desired prototype shape. It also includes channels for the cooling fluid to circulate, as well as features for the ejector pins. The design and construction of the mold are highly specialized. A well - designed mold can produce high - quality prototypes with tight tolerances, while a poorly designed mold can lead to defects such as warping, incomplete filling, or flash.

Considerations Before Starting Prototyping Injection Molding

Material Selection

Selecting the right plastic material is a cornerstone of successful prototyping injection molding. The material you choose can significantly impact the functionality, appearance, and cost of your prototype.

Material Performance: Different plastic materials have distinct properties. For example, ABS (Acrylonitrile Butadiene Styrene) is known for its high impact - resistance, making it ideal for products like electronic device housings. It can withstand drops and knocks without easily cracking. On the other hand, PLA (Polylactic Acid) is a biodegradable material, often used in applications where environmental friendliness is a priority, such as disposable cutlery or packaging for eco - conscious products. Polypropylene, with its excellent chemical resistance, is suitable for containers that will hold various substances, like chemical storage bottles. Consider the mechanical, thermal, and chemical requirements of your product. If your prototype will be exposed to high temperatures, a material with a high heat - deflection temperature, such as PEEK (Polyether Ether Ketone), might be necessary. PEEK can maintain its structural integrity at temperatures up to 260°C, making it suitable for aerospace and automotive applications where high - temperature resistance is crucial.

Cost Considerations: Material cost is also a vital factor. Some high - performance engineering plastics can be quite expensive. For instance, PEEK is significantly more costly than common plastics like ABS or polypropylene. If you're on a tight budget, especially for initial prototyping, you might opt for more cost - effective materials like PLA or ABS. However, if the final product requires specific high - end properties, the investment in a more expensive material during prototyping can be justified, as it will accurately represent the final product's performance. Additionally, consider the availability of the material. Some specialized plastics might have limited sources, which could lead to supply chain issues and higher costs due to shipping or minimum order requirements.

Design for Manufacturing (DFM)

Design for Manufacturing (DFM) principles are essential to ensure a smooth prototyping injection molding process and a high - quality final product.

Avoiding Thin Walls in the Mold: In the mold, thin walls, often referred to as "thin iron" in the industry, can be a major problem. When two features in a plastic part are very close together, the corresponding area in the mold will have a thin wall. As shown in Figure 1 below, this can lead to a weak mold structure. A thin - walled mold section is more likely to break or wear out quickly during the injection molding process. This not only increases the cost of mold maintenance and replacement but can also cause inconsistent part quality, such as incomplete filling of the plastic in the thin - walled area of the part.

**

Ensuring Uniform Part Wall Thickness: Uniform part wall thickness is crucial. When the wall thickness of a plastic part varies significantly, it can cause uneven cooling and shrinkage during the molding process. For example, if one section of a part is much thicker than another, the thicker section will take longer to cool. As a result, the part may warp, as shown in Figure 2. Uneven wall thickness can also lead to the formation of internal stresses, which can cause the part to crack over time. The ideal is to have a consistent wall thickness throughout the part. If a change in thickness is necessary, it should be done gradually, with a smooth transition between thick and thin areas.

**

In addition to these, other DFM considerations include proper draft angles for easy part ejection from the mold, and avoiding complex undercuts that can make mold design and part removal extremely difficult. By adhering to DFM principles, product developers can save time, reduce costs, and improve the overall quality of their prototyping injection molding projects.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology deeply understands the significance of prototyping injection molding. Our expertise lies in offering tailored solutions to meet diverse client needs.

We have a state - of - the - art facility equipped with advanced injection molding machines, capable of handling a wide range of plastic materials. Our in - house design team is proficient in applying Design for Manufacturing (DFM) principles, ensuring that every mold we create is not only structurally sound but also optimized for efficient production.

Our services cover the entire prototyping injection molding process, from initial design consultation to final product delivery. We assist clients in material selection, leveraging our knowledge of various plastic materials' properties to recommend the most suitable option. During the molding process, we maintain strict quality control, ensuring high - precision prototypes with tight tolerances.

Moreover, we pride ourselves on our quick turnaround times, allowing product developers to accelerate their development cycles. Whether it's a small - scale prototype for a startup or a large - scale production run for an established enterprise, Yigu Technology is committed to providing top - notch service and high - quality products.

FAQs

What types of plastics are commonly used in prototyping injection molding?

Commonly used plastics in prototyping injection molding include ABS (Acrylonitrile Butadiene Styrene), which offers high impact - resistance, making it suitable for products like electronic device casings. PLA (Polylactic Acid) is biodegradable, often used in eco - friendly applications such as disposable tableware. Polypropylene has excellent chemical resistance, ideal for containers holding various substances. PET (Polyethylene Terephthalate) is known for its high strength and clarity, frequently used in beverage bottles and packaging. Each plastic has unique properties that should be considered based on the prototype's requirements.

How long does the prototyping injection molding process usually take?

The prototyping injection molding process typically takes anywhere from a few minutes to a few hours. A simple, small - scale prototype might be completed in as little as 5 - 15 minutes, including the time for material preparation, injection, cooling, and ejection. However, for more complex prototypes with intricate designs or larger sizes, the process can take up to 2 - 3 hours. Factors that influence the time include the complexity of the mold, the type of plastic material (as different plastics have different melting and cooling times), and the cycle time of the injection molding machine.

Can prototyping injection molding be used for small - batch production?

Yes, prototyping injection molding can be effectively used for small - batch production. It offers several advantages in this context. Firstly, it allows for quick production of a limited number of parts, which is useful for market testing or for fulfilling small orders. The tooling cost for prototyping injection molding is relatively lower compared to full - scale production molds, making it cost - effective for small - batch runs. Additionally, it enables easy design changes between batches. If any improvements or modifications are needed, they can be implemented without significant additional cost or time, ensuring that the small - batch products can be optimized to meet specific requirements.