Finding the right partner for your plastic injection molding or other molding projects is a critical business decision. The chosen molding company becomes an extension of your team, directly impacting your product's quality, cost, and time-to-market. With countless options available, from small custom molding shops to large-scale injection molding manufacturers, the selection process can be daunting. This comprehensive guide is designed to cut through the noise. We'll walk you through the essential criteria—from service types and quality certifications to technical capabilities and cost structures—that truly separate the industry leaders from the rest. By the end, you'll have a clear, actionable framework to identify and partner with a molding company that aligns perfectly with your technical needs and business goals.

What Types of Molding Services Do Leading Companies Provide?

A top-tier molding company typically offers a diverse portfolio of processes, allowing them to match the best technology to your specific part requirements. Understanding these services is the first step in vetting potential partners.

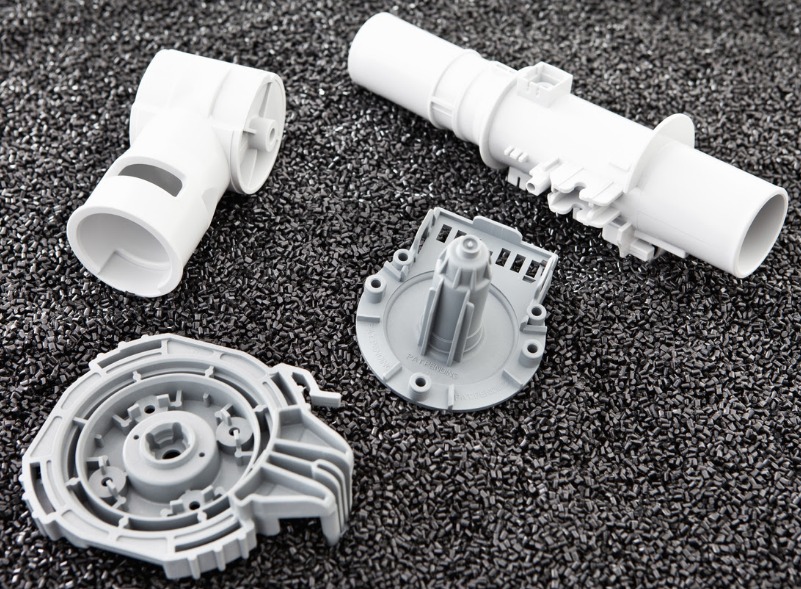

- Injection Molding: The most common process, ideal for high-volume production of complex, precise parts. Look for expertise in various materials like engineering-grade thermoplastics, liquid silicone rubber (LSR), and overmolding.

- Blow Molding: Used for creating hollow parts, such as bottles, containers, and automotive ducts. Key subtypes include extrusion and injection blow molding.

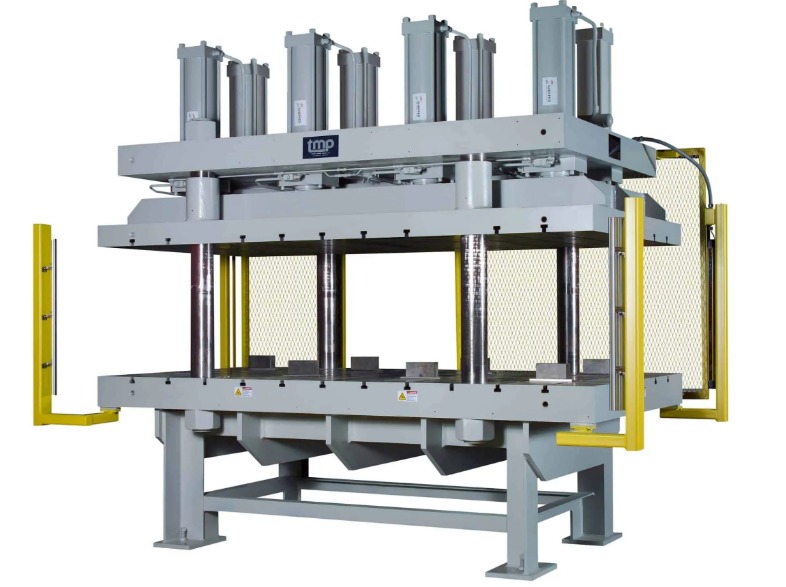

- Compression & Transfer Molding: Often employed for thermoset materials, composites, or rubber, this is common for electrical components, appliance housings, and high-strength parts.

- Rotational Molding: Best for large, hollow, one-piece items like tanks, kayaks, and industrial containers, offering low-cost tooling for lower-volume runs.

Why it Matters: A provider with multiple molding capabilities can offer unbiased advice on the most cost-effective and performance-optimal process for your design. For instance, a company experienced in both injection molding and thermoforming can objectively guide you if your large enclosure is better suited for one process over the other.

Quality Certifications and Standards to Prioritize

Certifications are a tangible indicator of a company's commitment to systematic quality and consistency. Prioritizing these standards mitigates your risk.

- ISO 9001: The baseline for a Quality Management System (QMS). It demonstrates a process-driven approach to meeting customer and regulatory requirements.

- IATF 16949: The essential certification for automotive molding. It builds upon ISO 9001 with far stricter requirements for continuous improvement, defect prevention, and supply chain management.

- ISO 13485: Critical for medical device manufacturing. It specifies requirements for a QMS where an organization needs to demonstrate its ability to provide medical devices that consistently meet customer and regulatory requirements.

- Industry-Specific Standards: These may include UL certification for electrical components, FDA CFR Title 21 compliance for food-contact or medical parts, and compliance with aerospace standards like AS9100.

Expert Insight: Don't just check the certificate. During a facility audit, ask to see how these standards are implemented. For example, how is First Article Inspection (FAI) documented per AS9102? How are Statistical Process Control (SPC) charts used on the production floor for critical part dimensions? The answers reveal the depth of their quality culture.

What Factors Influence Pricing and Cost Structures?

Understanding the drivers behind a molding quote helps in budgeting and negotiating. Costs are not arbitrary; they are built from specific, quantifiable factors.

| Cost Driver | Description | Impact on Price |

|---|---|---|

| Part Design & Complexity | Number of undercuts, tight tolerances, surface finish requirements, thin walls. | High complexity increases tooling cost and cycle time. |

| Material Selection | Commodity resin vs. specialized engineering plastic or medical-grade material. | Material cost can vary by a factor of 10 or more. |

| Tooling (Mold) Investment | Size, steel quality (e.g., P20 vs. hardened stainless), number of cavities, high-precision machining. | A major upfront capital cost; higher quality tooling lasts longer and produces better parts. |

| Production Volume | Prototype, low-volume, or high-volume run. | High volumes amortize tooling costs and benefit from lower per-part cycle times. |

| Secondary Operations | Assembly, painting, ultrasonic welding, pad printing, packaging. | Adds labor, equipment, and time to the unit price. |

Case Example: A startup needed a complex silicone overmolded component. One supplier quoted a very low per-part price but high tooling cost using a multi-cavity mold. A second supplier, understanding the startup's need for flexibility, proposed a single-cavitatool with a lower upfront cost and a slightly higher per-part price. This alignment with the client's cash flow and market validation stage built a more sustainable partnership.

Production Capacity and Typical Lead Times

A company's capacity must align with your project scale and timeline. Key questions to address:

- Machine Tonnage and Platen Size: Does their fleet range from small (<100 ton) machines for **precision miniature components** to large (>1000 ton) presses for automotive parts? This determines the part size they can produce.

- Facility Footprint and Shift Patterns: Can they scale production through multiple shifts? What is their maximum monthly output in terms of machine hours or part count?

- Lead Time Realism: A trustworthy partner provides transparent, phased lead times:

- Prototyping: 2-6 weeks (using soft tooling or rapid prototyping alongside initial mold design).

- Tooling Fabrication: 8-16 weeks (for a production-grade mold, depending on complexity).

- Production Ramp-up: 1-4 weeks after sampling approval and process validation.

Pro Tip: Ask about their supply chain resilience for raw materials. Leading companies have diversified supplier networks and safety stock policies to mitigate shortages and ensure on-time delivery.

Technical Capabilities and Modern Equipment Assessment

This is where true engineering partnership is forged. Move beyond machine lists to understand their problem-solving depth.

- In-House Design & Engineering (DfM): The best mold makers and manufacturing partners offer Design for Manufacturability analysis upfront. They should proactively suggest modifications to reduce cost, improve strength, or simplify assembly.

- Advanced Process Technologies: Look for capabilities that solve specific challenges:

- Two-Shot / Multi-Material Molding: For integrally molded seals, soft-grip surfaces, or multi-color parts.

- Micro-Molding: For medical and electronic components with micron-level tolerances.

- Gas-Assist or Water-Assist Injection: To create large, rigid parts with hollow sections and minimal sink marks.

- Quality Assurance Technology: Modern equipment is non-negotiable:

- Coordinate Measuring Machines (CMM) for 3D part inspection.

- Vision Inspection Systems for high-speed quality checks.

- Mold Flow Analysis Software (e.g., Moldflow) to simulate filling, cooling, and warpage before cutting steel, preventing costly tool revisions.

Industry Trend: The integration of Industrial Internet of Things (IIoT) sensors on molds and machines is becoming a key differentiator. This enables predictive maintenance, real-time process monitoring, and data-driven optimization for consistent quality.

Conclusion

Selecting the best molding company is a strategic evaluation that goes far beyond comparing price per piece. It requires a holistic assessment of their technical capabilities, quality systems, and cultural fit as a long-term partner. By methodically investigating the types of molding services offered, the rigor behind their quality certifications, the transparency of their cost structures, the scalability of their production capacity, and the sophistication of their modern equipment, you equip yourself to make an informed, confident decision. The right partner will act as a true extension of your engineering team, leveraging their expertise in plastic injection molding and custom manufacturing to de-risk your project and drive your product's success in the market.

FAQ

- What is the main difference between a molding company and a mold maker?

A mold maker (or toolmaker) specializes in designing and fabricating the precision molds (tools) used in the molding process. A full-service molding company typically includes mold making but also handles the entire production process: material procurement, molding, quality control, and secondary operations. - How many quotes should I get for a new molding project?

It's advisable to obtain 3-4 detailed quotes. This range provides a clear view of the market rate and reveals differing approaches to tooling design, material selection, and production planning, offering valuable insights beyond just price. - What are the biggest red flags when evaluating a potential molder?

Key red flags include: reluctance to provide a Design for Manufacturability (DfM) review, lack of clear quality certifications relevant to your industry, vague or overly optimistic lead time promises, and an unwillingness to facilitate an on-site audit of their facilities. - Is it better to use a local or overseas molding company?

The choice depends on priorities. Local/domestic partners offer easier communication, tighter IP control, faster iteration cycles, and lower shipping costs/logistics complexity. Overseas molders may offer lower labor rates but involve challenges in time zones, language, logistics, and protecting proprietary designs. For complex or rapidly evolving projects, proximity often provides greater net value. - What should I prepare before contacting a molder for a quote?

To get an accurate and comparable quote, prepare: 1) Detailed 3D CAD files (STEP or IGES), 2) A specification sheet outlining material, critical dimensions/tolerances, cosmetic requirements, and desired surface finish, 3) Target annual volumes, and 4) A requested timeline for prototypes and production.

Contact Yigu Technology for Custom Manufacturing.

Are you looking for a manufacturing partner that embodies the principles outlined in this guide? Yigu Technology combines deep engineering expertise with a robust, certified quality system to deliver exceptional custom plastic injection molding solutions. From complex, tight-tolerance parts for the medical and automotive industries to high-volume consumer goods, our integrated services—including in-house mold design, advanced molding capabilities, and comprehensive secondary operations—ensure a seamless path from prototype to production.

Let's discuss how we can bring your project to life with precision, reliability, and value. Contact our engineering team today for a confidential consultation and Design for Manufacturability assessment.