What is Injection Molding?

Injection molding is a widely used manufacturing process that involves injecting molten material into a mold cavity, where it cools and solidifies to take the shape of the mold. This process is not only used for plastics but also for other materials like metals (in the form of metal injection molding, MIM) and rubber. It has become an essential technique in the production of a vast array of products due to its efficiency, precision, and versatility.

The history of injection molding dates back to the 19th century, with the development of the first injection molding machine in 1872 for processing celluloid. Since then, the technology has evolved significantly, with improvements in materials, machinery, and mold design. Today, injection molding is used in various industries, from automotive and aerospace to consumer goods and medical devices.

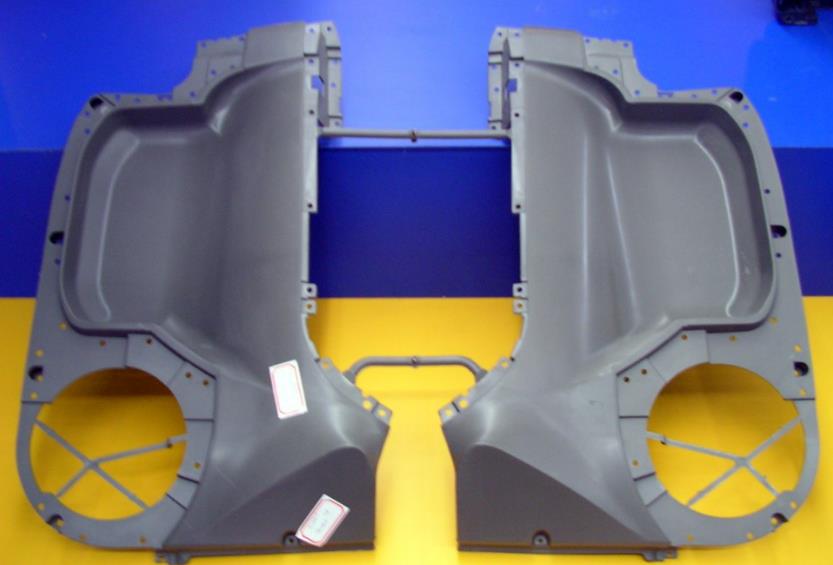

For example, in the automotive industry, many interior components such as dashboards, door panels, and steering wheels are made through injection molding. In the medical field, syringes, IV connectors, and prosthetics are often produced using this method. This process allows for the mass production of complex - shaped parts with high precision and repeatability.

The Injection Molding Process: A Step - by - Step Breakdown

Now that we have a basic understanding of what injection molding is, let's delve into the step - by - step process. This will help you appreciate the precision and complexity involved in creating high - quality injection - molded parts.

Plastic Raw Material Preparation

The process begins with the preparation of plastic raw materials. Most commonly, plastic comes in the form of pellets or powder. These are carefully loaded into the hopper of the injection molding machine. The type of plastic used depends on the requirements of the final product. For example, if you're making a high - strength automotive component, you might choose a type of engineering plastic like ABS (Acrylonitrile Butadiene Styrene), which offers a good balance of strength, toughness, and heat resistance. On the other hand, for a simple household item like a plastic cup, a more common plastic such as polyethylene could be used.

Heating and Melting

Once in the hopper, the plastic raw material is fed into the barrel of the injection molding machine. Inside the barrel, a screw or a plunger plays a crucial role. As the screw rotates (in the case of a screw - type injection molding machine) or the plunger moves, it pushes the plastic forward. The barrel is equipped with heating elements, which gradually heat the plastic. The temperature is carefully controlled to reach the melting point of the specific plastic being used. For instance, the melting point of polyethylene can range from about 110 - 130°C, while for ABS, it is typically around 200 - 250°C. As the plastic heats up, it transitions from a solid state to a highly viscous, molten state, becoming malleable and ready for the next stage.

Injection

The molten plastic, now in a flowing state, is the star of the show during the injection phase. A high - pressure system, usually provided by the injection unit of the machine, forces the molten plastic through a nozzle and into the mold cavity. The injection pressure can vary significantly depending on factors such as the complexity of the mold, the type of plastic, and the size of the part. For small, simple parts, an injection pressure of around 50 - 100 MPa (megapascals) might be sufficient. However, for larger or more intricate parts, the pressure could be as high as 200 - 300 MPa. This high - pressure injection ensures that the molten plastic fills every nook and cranny of the mold cavity, accurately replicating the shape designed in the mold.

Cooling and Solidification

Once the mold cavity is filled with molten plastic, the cooling process begins. The mold is typically made of metal, which is a good conductor of heat. Coolant, usually water, circulates through channels within the mold. As the heat from the molten plastic is transferred to the mold and then to the coolant, the plastic starts to cool and solidify. The cooling time is a critical factor. If the cooling is too fast, it can cause internal stresses in the part, leading to warping or cracking. On the other hand, if the cooling is too slow, it reduces the production efficiency. The cooling time can range from a few seconds for small, thin - walled parts to several minutes for larger, thicker - walled components. During this stage, the plastic gradually takes on the shape of the mold cavity and hardens into a solid part.

Mold Opening and Part Removal

After the plastic has cooled and solidified sufficiently, it's time to open the mold and retrieve the newly formed part. The mold consists of two halves, the stationary half (also known as the cavity) and the moving half (the core). The injection molding machine uses a clamping mechanism to hold the mold closed during the injection and cooling phases. Once the cycle is complete, the clamping force is released, and the moving half of the mold retracts, opening the mold. In some cases, ejector pins, which are small rods located within the mold, are used to push the part out of the mold cavity. These pins are strategically placed to ensure that the part is ejected smoothly without causing any damage.

Post - processing

In many cases, the injection - molded part is not ready for use immediately after removal from the mold. Post - processing steps are often required. One common post - processing task is the removal of flash, which is the thin excess plastic that may have squeezed out between the mold halves during injection. This can be removed manually using tools like knives or scissors, or through automated processes such as tumbling. Parts may also need to be trimmed to achieve the final desired dimensions. Additionally, some parts may require further finishing touches like painting for aesthetic purposes or adding a protective coating to enhance durability. For example, a plastic toy might be painted in bright colors to make it more appealing to children, while a medical device component could be coated with a biocompatible material to ensure safety when in contact with the human body.

Types of Injection Molding

Injection molding comes in various types, each tailored to specific materials, product requirements, and manufacturing needs. Understanding these different types can help manufacturers choose the most suitable process for their projects.

Conventional Plastic Injection Molding

This is the most common type of injection molding, widely used for producing a vast range of plastic products. In conventional plastic injection molding, molten plastic is injected into a mold cavity, where it cools and solidifies. The process is highly versatile and can produce parts with complex shapes and varying sizes. It is used in the production of everyday items such as plastic toys, household appliances, and packaging materials. For example, plastic storage containers like Tupperware are often made through conventional plastic injection molding. The process allows for high - volume production with relatively low cost per unit, making it an ideal choice for mass - produced plastic goods.

Metal Injection Molding (MIM)

Metal Injection Molding (MIM) involves mixing fine metal powder with a binder to form a feedstock. This feedstock is then injected into a mold cavity, just like in plastic injection molding. After injection, the molded part, known as a "green part," undergoes a series of post - processing steps. First, the binder is removed through a process called debinding or 脱脂,which can be done using methods such as thermal decomposition or solvent extraction. Then, the remaining metal powder is sintered at high temperatures. Sintering causes the metal particles to bond together, increasing the density and strength of the part. MIM is used in industries such as electronics, where small, high - precision metal components like connectors and brackets are required. In the medical field, it is used to produce surgical instruments and orthopedic implants due to its ability to create complex shapes with high precision and good mechanical properties.

Powder Injection Molding (PIM)

Powder Injection Molding (PIM) is a process used for producing high - precision products from metal or ceramic materials. It is similar to MIM but can also be applied to ceramic powders. The key difference between PIM and traditional injection molding lies in the preparation of the raw materials. In PIM, the feedstock consists of fine metal or ceramic powder mixed with a polymeric binder. The powder volume in the feedstock typically ranges from 40% - 60%. This mixture is then processed in a similar way to plastic injection molding. After injection, the parts go through debinding and sintering steps to achieve the final product. PIM is used in applications where high precision and complex geometries are required, such as in the production of electronic components, dental implants (when using ceramic materials), and small mechanical parts.

Foam Injection Molding (FIM)

Foam Injection Molding (FIM) is a process where a chemical or physical blowing agent is added to the plastic resin before injection. As the molten plastic is injected into the mold, the blowing agent decomposes or vaporizes, creating gas bubbles within the plastic. These bubbles cause the plastic to expand and form a foam - like structure as it cools and solidifies. The resulting parts have a lower density compared to traditional injection - molded parts, making FIM ideal for applications where weight reduction is crucial. For example, in the automotive industry, FIM is used to produce interior components like seat backs and armrests, which need to be lightweight yet still provide sufficient strength and comfort. It also offers advantages such as reduced material usage, lower injection pressures, and improved energy absorption properties.

Gas - Assisted Injection Molding (GAIM)

Gas - Assisted Injection Molding (GAIM) is a specialized injection molding process that uses gas (usually nitrogen) to help the molten plastic flow and fill the mold cavity. During the injection process, after a partial filling of the mold with molten plastic, high - pressure gas is injected into the plastic. The gas pushes the plastic to fill the remaining parts of the mold and can also create a hollow or partially hollow structure within the part. This is particularly useful for producing parts with thick sections, as it helps to reduce sink marks and internal stresses. GAIM is commonly used in the production of large - scale plastic products such as automotive bumpers, where the combination of a hollow structure and a solid outer skin provides a good balance of strength and weight. It is also used in the manufacturing of furniture components and some industrial parts where specific density requirements and the need for internal cavities are important factors.

Applications of Injection Molding

Injection molding's versatility makes it an essential manufacturing process across a wide range of industries. Here are some of the key sectors where injection molding plays a crucial role:

Consumer Electronics

In the fast - paced world of consumer electronics, injection molding is used to create many components. For example, the outer casings of smartphones are typically made through injection molding. This process allows for the production of sleek, lightweight, and durable designs. The use of high - strength plastics like polycarbonate in injection molding ensures that the phone cases can withstand everyday wear and tear. In addition, various internal components such as brackets, connectors, and even some small gears in laptops and tablets are also injection - molded. These components need to be precise in size to fit together perfectly within the compact design of modern electronic devices.

Automotive Industry

The automotive industry heavily relies on injection molding for the production of numerous parts. Dashboards, which are large and have complex shapes, are made using injection molding. The process enables the integration of features like instrument clusters, air vents, and storage compartments into a single, seamless unit. Headlamp and taillamp housings are another example. These parts require materials with high heat resistance and impact strength, such as acrylonitrile - styrene - acrylate (ASA) or polypropylene (PP) with special additives. Injection molding allows for the mass production of these housings with consistent quality, meeting the high - volume demands of the automotive assembly lines.

Medical Devices

In the medical field, injection molding is used to produce a variety of products. Syringes are one of the most common examples. The process ensures the production of syringes with precise dimensions, smooth inner walls for easy plunger movement, and high - quality materials that are biocompatible and meet strict medical standards. Medical instrument housings, such as those for ultrasound machines, electrocardiogram (ECG) monitors, and surgical tools, are also injection - molded. These housings need to protect the delicate internal components while being easy to clean and sterilize. Materials like medical - grade ABS or polyether ether ketone (PEEK) are often used due to their excellent chemical resistance and mechanical properties.

Daily Necessities

In our daily lives, we encounter countless injection - molded products. Plastic bottle caps are a simple yet essential example. Injection molding allows for the mass production of caps with consistent thread patterns for a tight seal. Kitchen utensils like spatulas, spoons, and mixing bowls are also commonly made through this process. The ability to use different colors and materials gives these products both functionality and aesthetic appeal. Toys, especially plastic toys, are another major application. Injection molding can create toys with complex shapes, moving parts, and bright colors, making them attractive to children. For instance, action figures, building blocks, and toy cars are all produced in large quantities using injection molding.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience in the injection molding field. We understand the nuances of different injection molding processes and can handle complex custom - made requirements. Our team of experts can provide high - quality custom services, from the initial product design to the final production. We use advanced equipment and strict quality control measures to ensure that each product meets the highest standards. Whether it's plastic or metal injection molding, we can offer a one - stop solution according to the specific needs of our customers, helping them bring their innovative ideas to life efficiently and accurately.

FAQs

What is the difference between injection molding and injection casting?

Injection molding involves injecting molten material, often plastics, under high pressure into a mold cavity. The material cools and solidifies within the mold to take its shape. On the other hand, injection casting typically refers to a process where molten metal is poured or injected, usually under lower pressure or sometimes even just by gravity, into a mold. The main differences lie in the materials used (plastics in injection molding, often metals in injection casting), the pressure levels applied (high in injection molding, relatively lower in injection casting), and the types of products they are used to manufacture. For example, injection molding is used for making plastic toys and consumer electronics casings, while injection casting might be used for small metal components like jewelry or some small - scale metal machine parts.

Can injection molding be used for all types of plastics?

Injection molding is mainly suitable for thermoplastic plastics. Thermoplastics can be melted and re - solidified multiple times, which makes them ideal for the injection molding process. Examples of thermoplastics commonly used in injection molding include polyethylene (PE), polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC). However, thermosetting plastics have some limitations in injection molding. Thermosetting plastics, such as phenolic resins and epoxy resins, undergo a chemical reaction during curing that is irreversible. Once they are cured, they cannot be remelted and reshaped easily. While it is possible to injection - mold some thermosetting plastics, the process is more complex and not as common as for thermoplastics due to their chemical nature and the need for careful control of the curing process during injection.

How to ensure the quality of injection - molded products?

To ensure the quality of injection - molded products, several key factors need to be considered. First, the quality of the raw materials is crucial. Using high - quality plastics with consistent properties helps in achieving uniform parts. Second, precise control of the injection molding process parameters is essential. This includes maintaining the correct temperature of the barrel, injection pressure, and injection time. For example, if the temperature is too high, the plastic may degrade; if the pressure is too low, the mold may not fill completely. Third, proper mold design and maintenance are necessary. A well - designed mold with good venting and cooling channels can prevent issues like air traps and uneven cooling. Regular mold maintenance, such as cleaning and checking for wear and tear, also ensures consistent quality. Finally, quality inspection during the production process, including visual inspection for defects like flash, warping, or voids, and dimensional checks using tools like calipers or coordinate measuring machines (CMMs), helps in identifying and rectifying any quality issues promptly.