What is a Rapid Tooling Factory?

A Rapid Tooling Factory is a specialized manufacturing facility that focuses on the rapid production of tools, molds, and dies. These tools are essential for various manufacturing processes, especially injection molding, which is crucial for producing high - quality plastic parts.

In the traditional manufacturing model, tooling production can be a time - consuming and expensive process. For Yigu Technology example, creating a custom injection mold using conventional methods might take weeks or even months. This long lead time can be a significant bottleneck, especially when companies need to quickly bring new products to market or make design changes.

Rapid Tooling Factories, on the other hand, utilize advanced technologies such as 3D printing (also known as additive manufacturing), CNC (Computer Numerical Control) machining, and rapid prototyping techniques. With 3D printing, for instance, a mold can be built layer by layer directly from a digital design file. This not only speeds up the production process but also allows for greater design flexibility. Complex geometries that would be extremely difficult or even impossible to achieve with traditional machining can be easily printed.

The role of a Rapid Tooling Factory in the manufacturing industry is multi - faceted. Firstly, it enables companies to quickly test and iterate product designs. By rapidly producing prototype molds, manufacturers can produce small batches of parts for functional and aesthetic testing. This reduces the risk of costly design flaws being discovered late in the production cycle. Secondly, for low - volume production runs, rapid tooling is a cost - effective solution. Instead of investing a large amount of time and money in traditional, high - precision, and expensive molds that are more suitable for high - volume production, companies can use the more affordable and quickly produced tools from a Rapid Tooling Factory.

To illustrate the significance of Rapid Tooling Factories, consider the automotive industry. When developing a new car model, manufacturers need to produce prototypes of various interior and exterior components. A Rapid Tooling Factory can quickly provide the molds for these components, allowing for faster design validation and shortening the overall development time of the new vehicle.

The Core of Rapid Tooling Factory: Low - Volume Injection Molding

Low - volume injection molding is a crucial service provided by Rapid Tooling Factories. It bridges the gap between prototyping and high - volume production, offering a cost - effective solution for companies that need to produce a relatively small number of plastic parts.

The Basics of Low - Volume Injection Molding

- Raw Material Preparation

- The process begins with the selection of the appropriate plastic material. Common materials include ABS (Acrylonitrile Butadiene Styrene), PP (Polypropylene), and PC (Polycarbonate). Each material has its own unique properties; for Yigu Technology example, ABS is known for its strength and impact - resistance, making it suitable for products like electronic device housings. The plastic comes in the form of pellets, which are fed into the hopper of the injection - molding machine.

- Mold Design

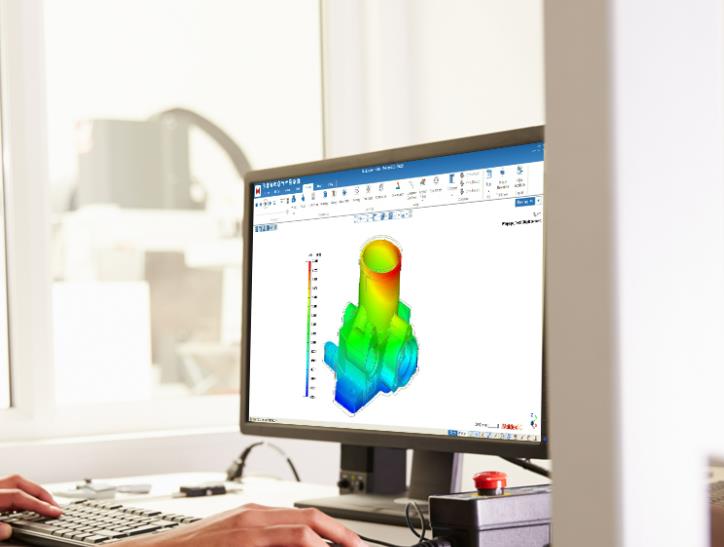

- A well - designed mold is the key to successful low - volume injection molding. The mold is typically made of steel or aluminum. With the help of CAD (Computer - Aided Design) software, designers can create highly precise 3D models of the mold. These models are then transferred to CAM (Computer - Aided Manufacturing) systems for machining. For low - volume production, molds can be designed with a focus on simplicity and cost - effectiveness, while still ensuring the quality of the final parts. For instance, some molds may use a single - cavity design when only a small number of identical parts are needed.

- The Injection Process

- Once the mold is ready and the plastic material is in the hopper, the injection process starts. The plastic pellets are melted as they move through the heated barrel of the injection - molding machine. A reciprocating screw is used to push the molten plastic forward. When the required amount of molten plastic is accumulated at the front of the screw, the screw moves forward rapidly, injecting the molten plastic into the closed mold cavity at high pressure. The injection pressure can range from 500 to 3000 bar, depending on the complexity of the part and the plastic material used.

- Cooling and Demolding

- After the mold is filled with molten plastic, it enters the cooling phase. Cooling channels are integrated into the mold to circulate a cooling medium, usually water. The cooling process typically takes 10 - 30 seconds, but it can vary based on the size and thickness of the part. Once the plastic has cooled and solidified enough, the mold opens, and the part is ejected. Ejector pins, located in the mold, push the part out of the cavity.

Key Components in Low - Volume Injection Molding

- Injection Molding Machine

- This is the heart of the low - volume injection - molding process. Injection - molding machines come in various sizes and capacities. For low - volume production, smaller - sized machines with a clamping force ranging from 50 to 200 tons are often sufficient. These machines are equipped with features such as variable - speed drives for the screw, which allow for precise control of the injection speed and pressure. They also have temperature - control systems to ensure that the plastic is melted at the optimal temperature. For example, an injection - molding machine with a smaller footprint can be more cost - effective for a Rapid Tooling Factory that focuses on low - volume orders, as it takes up less space in the production facility.

- Mold

- As mentioned before, the mold determines the shape and size of the final product. A mold consists of two main parts: the cavity (female part) and the core (male part). The cavity is where the molten plastic is injected, and the core helps to form the internal features of the part. Molds can be designed with different types of gating systems (the channels through which the molten plastic enters the mold cavity), such as side gates, point gates, or tunnel gates. The choice of gating system depends on factors like the shape of the part and the desired surface finish.

- Cooling System

- A well - designed cooling system is essential for efficient low - volume injection molding. The cooling system consists of a network of channels within the mold. The cooling medium (usually water) flows through these channels, absorbing heat from the molten plastic and causing it to solidify. The layout of the cooling channels can significantly impact the cooling time and the quality of the part. For Yigu Technology example, if the cooling channels are not evenly distributed, the part may cool unevenly, leading to warping or internal stresses. In some cases, conformal cooling channels, which are designed to follow the shape of the part more closely, can be used to improve cooling efficiency, especially for complex - shaped parts.

Benefits of Low - Volume Injection Molding in a Rapid Tooling Factory

Cost - Efficiency

Low - volume injection molding in a rapid tooling factory offers significant cost - saving advantages. Firstly, consider the mold - making cost. Traditional high - volume injection molds can be extremely expensive. For example, a complex, high - precision mold for large - scale production might cost anywhere from \(50,000 to \)200,000. In contrast, molds for low - volume injection molding, often made with less expensive materials like aluminum or through rapid prototyping techniques such as 3D printing, can cost as little as \(5,000 to \)20,000. This is a substantial reduction, especially for companies with limited budgets or those that are unsure about the market demand for a new product.

Secondly, low - volume injection molding helps in reducing inventory costs. Since only a small number of parts are produced at a time, there is no need to store large quantities of finished products. A study by a manufacturing research firm found that companies that switched to low - volume injection molding reduced their inventory - holding costs by an average of 30%. For instance, a small - scale consumer electronics company used to keep a three - month inventory of plastic casings for its products. After adopting low - volume injection molding, it was able to reduce its inventory to a one - month supply, freeing up capital that was previously tied up in inventory.

Time - Saving

Compared to traditional high - volume injection molding, low - volume injection molding in a rapid tooling factory can significantly shorten the product development cycle. Traditional injection molding, which involves complex mold design, precision machining, and extensive testing, can take 4 - 8 weeks from the initial design to the production of the first batch of parts.

In a rapid tooling factory, the use of advanced technologies accelerates this process. With 3D - printed molds, the mold - making time can be reduced to as little as 1 - 2 weeks. This allows companies to quickly move from the design stage to the production of functional prototypes and small - scale production runs. For example, a startup in the medical device industry needed to quickly test a new design for a diagnostic device. By using low - volume injection molding in a rapid tooling factory, they were able to produce the first batch of parts within 10 days, compared to the 6 - week lead time they would have faced with traditional injection molding. This speed advantage enables companies to respond more quickly to market changes, launch products faster, and gain a competitive edge.

Flexibility

Low - volume injection molding provides remarkable flexibility in product design and production. In the early stages of product development, design changes are often inevitable. With low - volume injection molding, making design modifications is relatively easy and cost - effective. Since the molds are less complex and expensive, a design change might only require a simple adjustment to the 3D model used for mold production. In contrast, in traditional high - volume injection molding, a design change often means costly mold re - engineering or even the creation of an entirely new mold, which can cost tens of thousands of dollars.

Moreover, low - volume injection molding is ideal for customized production. Different customers may have unique requirements for product features, colors, or sizes. A rapid tooling factory can easily accommodate these customizations by making minor adjustments to the mold or the injection - molding process. For example, a toy company might want to produce a limited - edition run of a popular toy with a special color scheme or additional accessories. Low - volume injection molding allows them to do this without the high costs associated with setting up a large - scale production line for a small, customized batch.

Comparison with Traditional Tooling and High - Volume Injection Molding

Cost Comparison

The cost structure of rapid tooling for low - volume injection molding, traditional tooling, and high - volume injection molding varies significantly. The following table outlines the cost differences:

| Cost Aspect | Rapid Tooling for Low - Volume Injection Molding | Traditional Tooling | High - Volume Injection Molding |

| Mold Cost | Low. Molds are often made of less expensive materials like aluminum or through 3D printing. Costs can range from \(5,000 - \)20,000. | High. Precision molds made of high - grade steel, costing from \(50,000 - \)200,000 or more. | High. Similar to traditional tooling, as high - volume molds require high - precision and durability, with costs in the same high range. |

| Production Cost per Unit | Higher than high - volume injection molding but lower than traditional tooling for small quantities. Due to shorter production runs, the cost per unit is spread over fewer parts. | High for small production runs. Since the high mold cost is spread over a small number of parts, the cost per unit is very high for low - volume production. | Low. As the production volume increases, the high mold cost is spread over a large number of parts, reducing the cost per unit significantly. |

| Setup Cost | Relatively low. The use of advanced technologies like 3D printing and simplified mold designs reduces setup time and cost. | High. Complex mold designs and precision machining require a lot of time and resources for setup. | High. Similar to traditional tooling, high - volume injection molding needs careful setup for large - scale production. |

Time Comparison

The time required for each production method also varies greatly. The following bar chart (you can create a simple bar chart with software like Excel to visualize this data better) shows the approximate production cycle times:

| Production Method | Design to First Part Time | Production Time per Batch |

| Rapid Tooling for Low - Volume Injection Molding | 1 - 2 weeks | A few days to a week for a small batch (depending on batch size) |

| Traditional Tooling | 4 - 8 weeks | 1 - 2 weeks for a batch (longer setup time) |

| High - Volume Injection Molding | 4 - 8 weeks | 1 - 2 weeks for a large - scale batch (longer production runs) |

Production Volume and Product Variety Comparison

- Production Volume:

- Rapid Tooling for Low - Volume Injection Molding: Ideal for production volumes ranging from a few dozen to a few thousand parts. It is not cost - effective for extremely high - volume production, but it fills the gap between prototyping and full - scale mass production.

- Traditional Tooling: Can be used for low - volume production, but it is more suitable for medium - volume production runs (a few thousand to tens of thousands of parts). For very low - volume production, the high mold cost makes it uneconomical.

- High - Volume Injection Molding: Designed for large - scale production, with production volumes often in the hundreds of thousands or even millions of parts. It takes full advantage of economies of scale.

- Product Variety:

- Rapid Tooling for Low - Volume Injection Molding: Offers high flexibility in product variety. Design changes can be made easily, and different product variations can be produced in small batches. This is great for product development, custom orders, and limited - edition products.

- Traditional Tooling: Moderate flexibility. While design changes are possible, they are more time - consuming and costly. It is better suited for producing products with relatively stable designs.

- High - Volume Injection Molding: Low flexibility in terms of product variety for small - scale changes. Once the mold is set up for high - volume production, making significant design changes can be extremely expensive and time - consuming. It is best for producing large quantities of identical products.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the role of Rapid Tooling Factories and low - volume injection molding. In our business, we often encounter clients with urgent needs for small - batch, customized products. The advanced technologies in Rapid Tooling Factories, especially low - volume injection molding, enable us to quickly turn around these projects.

For example, when developing a new product prototype for a client in the electronics industry, we used low - volume injection molding to produce plastic casings. This not only saved time but also allowed for cost - effective design adjustments based on the client's feedback. We believe that in the future, with the continuous development of technology, Rapid Tooling Factories will play an even more significant role. The integration of artificial intelligence and machine learning in mold design and production processes will further improve efficiency and product quality, meeting the ever - changing needs of the market.

FAQ about Rapid Tooling Factory and Low - Volume Injection Molding

What types of materials can be used in low - volume injection molding in a rapid tooling factory?

A variety of materials can be used in low - volume injection molding in a rapid tooling factory. Common plastic materials include:

- ABS (Acrylonitrile Butadiene Styrene): It is known for its excellent impact - resistance, strength, and good surface finish. ABS is widely used in the production of electronic device housings, automotive interior components, and toys. For example, the outer shell of a game console is often made of ABS due to its ability to withstand impacts during normal use.

- PP (Polypropylene): PP has good chemical resistance, high heat resistance, and is relatively lightweight. It is commonly used in the production of food containers, automotive parts like bumpers, and consumer goods such as plastic chairs. Its resistance to chemicals makes it suitable for storing various substances in the food and beverage industry.

- PC (Polycarbonate): PC offers high - strength, excellent optical properties, and heat resistance. It is often used in applications where transparency and durability are required, such as in eyewear lenses, safety helmets, and electronic display panels.

How accurate are the products produced by low - volume injection molding in a rapid tooling factory?

The accuracy of products produced by low - volume injection molding in a rapid tooling factory can be quite high. Typical dimensional tolerances usually range from ±0.1 - ±0.5 mm, depending on several factors. The complexity of the part design plays a significant role. For simple - shaped parts, it is easier to achieve higher accuracy, often within the lower end of the tolerance range (around ±0.1 mm). However, for parts with complex geometries, such as those with intricate internal features or thin - walled sections, the tolerance may be closer to ±0.5 mm. The quality of the mold also affects accuracy. A well - made mold, whether it is machined by CNC or 3D - printed, with precise dimensions and proper surface finish, can contribute to more accurate parts. Additionally, the injection - molding process parameters, like injection pressure, temperature, and cooling rate, need to be carefully controlled to ensure dimensional stability and accuracy of the final product.

What is the typical lead time for a project in a rapid tooling factory for low - volume injection molding?

The typical lead time for a low - volume injection - molding project in a rapid tooling factory can vary. On average, it can range from 1 - 3 weeks. The initial mold - making stage usually takes 1 - 2 weeks. If the mold is being produced using 3D printing, it may be closer to 1 week, as 3D printing can quickly transform a digital design into a physical mold. However, if traditional CNC machining is used for mold production, it might take up to 2 weeks due to the more complex machining operations involved. After the mold is ready, the actual injection - molding production of a small batch (ranging from a few dozen to a few thousand parts) can take another 1 - 2 days to a week, depending on the batch size and the complexity of the parts. Factors that can affect the lead time include the availability of raw materials, the workload of the rapid tooling factory at the time of the order, and any potential design changes or revisions during the process.