What Exactly are Plastic Injection Molding Parts?

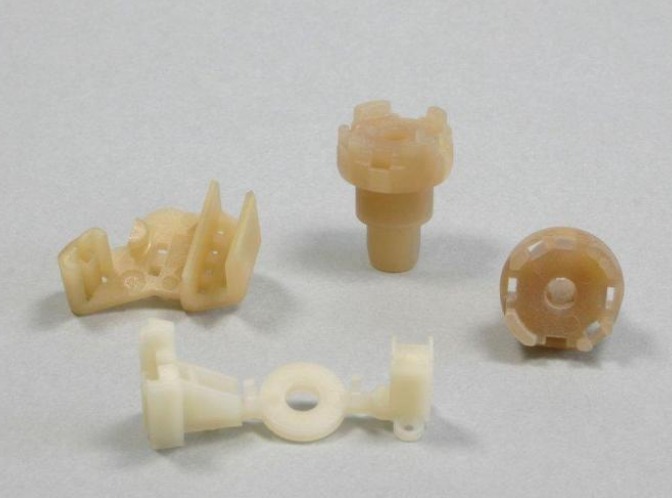

Plastic injection molding parts are products made by injecting molten plastic material into a mold cavity. This is a widely used manufacturing process in the plastic industry. During the process, plastic pellets are first heated until they reach a molten state. Then, under high pressure, this molten plastic is forced into a pre - designed mold cavity. After the plastic cools and solidifies inside the mold, it takes on the shape of the cavity, and the final plastic injection molding part is formed.

There is a wide variety of plastic injection molding parts in our daily lives. For example, electronic device housings such as mobile phone cases, laptop covers, and TV casings are often made through plastic injection molding. These parts need to have precise dimensions to fit all internal components perfectly. A mobile phone case, for instance, must have accurate cut - outs for the camera, buttons, and charging ports. In 2023, the global production of mobile phone cases reached over 10 billion units, with a significant portion being plastic injection - molded.

Automotive interior components are another common example. Dashboards, door panels, and steering wheel covers in cars are frequently plastic injection molding parts. They not only need to meet aesthetic requirements but also must be durable enough to withstand daily use in a vehicle. According to industry statistics, in the automotive industry, about 80% of interior non - structural parts are made by plastic injection molding.

Even household items like plastic utensils, toys, and storage containers are often the result of this process. A simple plastic spoon or a children's building block toy is produced with high precision and efficiency through plastic injection molding. In the toy market, which is worth billions of dollars globally, a large majority of plastic toys are plastic injection - molded products.

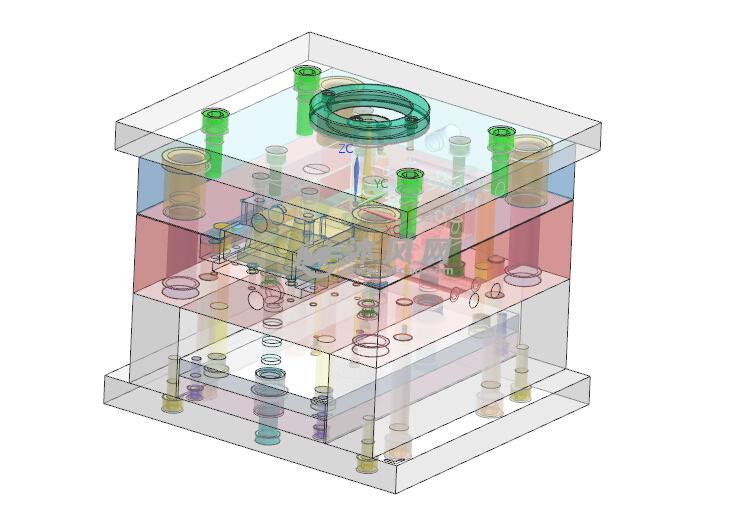

The Injection Molding Process in Detail

Understanding the plastic injection molding process is key to appreciating the quality and precision of plastic injection molding parts. This process is a well - orchestrated sequence of steps, each crucial for the final product's integrity.

1. Material Preparation

The process commences with material preparation. Plastic in the form of pellets or powder is placed into a hopper. Different types of plastic materials have unique properties, and choosing the right one is essential. For example, acrylonitrile butadiene styrene (ABS) is popular for its strength, heat resistance, and easy processability, often used in automotive and electronics parts. In contrast, polyethylene (PE) is known for its flexibility and chemical resistance, making it suitable for packaging and household items. The quality of the plastic raw material directly impacts the final product. High - quality pellets ensure consistent melting and better - formed parts.

2. Heating and Melting

Once in the hopper, the plastic material is pushed by a screw or a plunger into a heating zone. As it moves through the heated barrel, the plastic gradually melts. The temperature in this zone is precisely controlled according to the type of plastic. For instance, the melting temperature of ABS typically ranges from 200 - 250°C, while that of PE is around 120 - 180°C. This precise temperature control is crucial. If the temperature is too low, the plastic may not melt completely, leading to uneven parts with defects like voids or surface roughness. On the other hand, if it's too high, the plastic can degrade, losing its mechanical properties and changing color.

3. Injection

With the plastic now in a molten state, it's time for injection. High pressure, usually in the range of 50 - 200 MPa, is applied to force the molten plastic into the mold cavity. The injection speed also varies depending on the part's complexity and the plastic material. For small, intricate parts, a faster injection speed might be required to ensure the plastic fills all the details of the mold before it starts to cool. In contrast, for larger parts, a slower speed could be more suitable to prevent issues like air traps or flash (excess plastic in unwanted areas).

4. Cooling and Solidification

Once inside the mold, the molten plastic begins to cool and solidify. The mold is designed with a cooling system, often using water channels. The cooling time is a critical factor, as it affects the part's dimensional stability and production efficiency. For example, a thick - walled plastic part may require a longer cooling time compared to a thin - walled one. Cooling too quickly can cause internal stresses in the part, leading to warping or cracking. On average, the cooling time can range from a few seconds to several minutes, depending on the part's size and the plastic material.

5. Mold Opening and Part Ejection

After the plastic has solidified, the mold opens. The two halves of the mold separate, and the now - solid plastic part is left in one half. Ejection systems, such as ejector pins or air ejection, are then used to remove the part from the mold. Ejector pins are small rods that push the part out of the mold cavity. The design and placement of these pins are carefully planned to ensure the part is ejected smoothly without causing damage. In some cases, air ejection is used, where compressed air is blown into the mold to push the part out, which is especially useful for delicate parts.

6. Post - processing

The final step may involve post - processing. This can include removing flash (the thin excess plastic that forms around the edges of the part), trimming any remaining sprue (the channel through which the plastic entered the mold), and surface finishing. Surface finishing options like painting, plating, or texturing can enhance the part's appearance and functionality. For example, a plastic part for a consumer electronics product may be painted to match the brand's color scheme or textured to provide a better grip.

Why Choose Chinese Plastic Injection Molding Parts?

1. Cost - effectiveness

One of the most significant advantages of Chinese plastic injection molding parts is their cost - effectiveness. In 2023, China's labor cost for the manufacturing industry, on average, was much lower compared to developed countries. For example, the hourly wage for a manufacturing worker in the United States was around \(25, while in China, it was approximately \)5 - $8. This significant difference in labor cost directly contributes to the lower production cost of plastic injection molding parts.

Moreover, China has a well - developed supply chain for plastic raw materials. Local production of various plastics such as ABS, PE, and PP ensures a stable supply and relatively lower prices. For instance, the price of domestic ABS plastic pellets was about 10 - 15% lower than imported ones in 2023. This cost - advantage allows Chinese manufacturers to offer plastic injection molding parts at a more competitive price in the global market. A simple plastic toy produced through injection molding in China can be sold at a 30 - 40% lower price compared to the same product made in some European countries, mainly due to the cost - savings in labor and raw materials.

2. High - quality Manufacturing

China is not only cost - competitive but also excels in the quality of plastic injection molding parts. Many Chinese manufacturers have invested heavily in advanced production equipment. High - precision injection molding machines from well - known international brands are commonly used in Chinese factories. These machines can achieve extremely high injection pressure and precise control of injection volume, ensuring the accuracy of product dimensions. For example, some high - end injection molding machines can control the injection volume within an error range of ±0.1%, which is crucial for producing small and intricate parts.

In addition, Chinese manufacturers strictly adhere to international quality standards such as ISO 9001. Stringent quality control systems are implemented throughout the production process, from raw material inspection to the final product inspection. Before production, raw materials are tested for their physical and chemical properties to ensure they meet the required standards. During the production process, regular inspections are carried out to detect any potential defects early. After production, each part undergoes a comprehensive inspection for dimensions, appearance, and functionality. As a result, the defect rate of Chinese - made plastic injection molding parts has been significantly reduced, with many manufacturers achieving a defect rate of less than 1%.

3. Wide Range of Applications

Chinese plastic injection molding parts find applications in a vast number of industries. In the consumer electronics industry, companies like Huawei and Xiaomi rely on Chinese - made plastic injection molding parts for their device housings. These parts are not only aesthetically pleasing but also provide excellent protection for internal components. For example, the plastic housing of a Xiaomi smartphone, made through injection molding, is designed to be both lightweight and durable, with precise cut - outs for various ports and buttons.

In the automotive industry, many car manufacturers source plastic injection molding parts from China. Interior components such as dashboards, door panels, and seat covers are often made in China. A report in 2023 showed that about 30% of the plastic interior parts in cars sold globally were made in China. These parts are required to meet high - safety and durability standards, and Chinese manufacturers have proven their ability to produce high - quality products that can withstand the harsh environment inside a vehicle.

The medical industry also benefits from Chinese plastic injection molding parts. Disposable syringes, medical device casings, and laboratory equipment components are commonly made through injection molding in China. These parts must meet strict medical - grade quality requirements, and Chinese manufacturers have obtained relevant certifications such as CE and FDA to ensure the safety and quality of their products.

Even in the daily necessities industry, Chinese - made plastic injection molding parts are everywhere. From plastic buckets and storage containers to children's toys, these products are known for their affordability and good quality. For example, the popular plastic storage boxes sold in large - scale supermarkets around the world are often made in China, with features like tight - fitting lids and strong structures to meet the needs of daily use.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience and distinct advantages in the field of plastic injection molding.

Firstly, we are equipped with advanced injection molding equipment. Our state - of - the - art machines are capable of achieving high - pressure injection with extreme precision. For example, our high - end injection molding machines can control the injection volume within an error range of ±0.05%, much higher than the industry average of ±0.1%. This allows us to produce parts with extremely accurate dimensions, even for the most complex designs.

Secondly, our professional team is a key strength. Comprising of experienced engineers and technicians, they have in - depth knowledge of plastic materials, mold design, and the injection molding process. Our engineers can optimize the injection molding process according to different product requirements, ensuring high - quality production. They can also quickly solve any technical problems that arise during production, reducing production downtime.

Moreover, we offer customized services. Understanding that each customer has unique needs, we work closely with clients from the initial design stage. We provide comprehensive solutions, from material selection to mold design and production process optimization. Whether it's a small - batch production for a new product prototype or a large - scale production for mass - market products, we can meet the diverse needs of our customers.

In a nutshell, Yigu Technology is committed to providing high - quality plastic injection molding solutions, combining advanced technology, professional expertise, and customized services to help our customers achieve success in their respective industries.

FAQ

1. What are the common materials used for plastic injection molding parts in China?

In China, some of the most commonly used materials for plastic injection molding parts include:

- ABS (Acrylonitrile Butadiene Styrene): It offers a good balance of strength, heat resistance, and processability. ABS is often used in automotive parts like dashboards, and in electronics for device housings such as laptop covers. It has a melting temperature range of 200 - 250°C.

- PP (Polypropylene): Known for its light weight, high strength, and good heat resistance. PP can withstand higher temperatures compared to some other plastics, making it suitable for products like microwave - safe containers. Its melting point is around 160 - 170°C, and it is also used in automotive interior components and various household items.

- PC (Polycarbonate): PC has excellent transparency, high strength, and outstanding impact resistance. It is widely applied in the production of optical lenses, safety helmets, and electronic device screens. The melting temperature of PC is typically in the range of 220 - 260°C.

2. How to ensure the quality of plastic injection molding parts?

To ensure the quality of plastic injection molding parts, the following measures can be taken:

- Choose High - quality Materials: Start by selecting premium plastic raw materials. High - quality pellets have consistent properties, which is crucial for the final product. For example, ensure that the moisture content in the plastic pellets is within the specified range to prevent issues like voids or surface defects during molding.

- Control Production Process Parameters: Precise control of parameters such as temperature, pressure, and injection speed is essential. The melting temperature should be set according to the plastic material. For instance, if it's too low for ABS, the plastic may not flow properly into the mold, while if it's too high, the material may degrade. The injection pressure and speed also need to be adjusted based on the complexity of the part.

- Strict Quality Inspection: Implement a comprehensive quality inspection system. Inspect raw materials before production, conduct in - process inspections during molding, and perform final product inspections. Use tools like 3D scanners to check the dimensional accuracy of the parts, and perform visual inspections for surface defects such as scratches, cracks, or uneven surfaces.

3. What is the minimum order quantity for plastic injection molding parts in China?

The minimum order quantity (MOQ) for plastic injection molding parts in China varies depending on the supplier and the product.

- For small - scale local factories, the MOQ might be as low as 500 - 1000 pieces. These factories are often more flexible and can accommodate small - batch production, which is suitable for startups or those in need of product prototypes.

- Larger, more automated factories usually have a higher MOQ, typically around 5000 - 10000 pieces or even more. This is because large - scale production can better utilize their production capacity and reduce per - unit production costs. For example, a factory that specializes in mass - producing plastic toy parts may require a minimum order of 10000 pieces to make the production run cost - effective.