Understanding the Plastic Injection Molding Process

Before delving into how to choose a China mold company for your plastic injection molding project, it's crucial to understand the plastic injection molding process itself. Plastic injection molding is a manufacturing process for producing parts by injecting molten material into a mold.

The process begins with the plastic pellets being fed into a heated barrel. Here, a screw mechanism rotates, melting the plastic as it moves along the barrel. Once the plastic is fully molten, a high - pressure piston forces the melted plastic into a mold cavity. The mold cavity is designed to the exact shape of the final product you want to create. After the plastic has filled the mold, it is left to cool and solidify. Once cooled, the mold opens, and the newly formed plastic part is ejected.

For example, if you are manufacturing a plastic toy, the mold will be designed with the intricate details of the toy. The molten plastic will take on this shape inside the mold, and after cooling, you get a precisely shaped plastic toy.

Mold companies play a pivotal role in this process. They are responsible for designing and manufacturing the molds. A well - designed mold is essential for the quality of the final product. The mold must be able to withstand the high pressures and temperatures during the injection molding process. It also needs to have accurate dimensions so that the plastic parts produced are of the correct size and shape. A good mold can also contribute to faster production cycles, as it allows for efficient cooling and easy ejection of the parts. For instance, a mold with an optimized cooling system can reduce the cooling time of the plastic, thus increasing the number of parts that can be produced in a given time.

Key Factors to Consider When Selecting a China Mold Company

Experience and Expertise

Experience and expertise are the cornerstones of a reliable mold company. A China mold company with years of experience in plastic injection molding has likely encountered and overcome a wide range of challenges. They have a better understanding of different plastic materials, such as ABS, PP, and PVC, and know how to optimize the molding process for each type. For example, a company with 10 - 15 years of experience may have worked on projects for various industries, including automotive, electronics, and consumer goods. This diverse experience allows them to quickly adapt to different project requirements.

Moreover, an experienced company often has a team of highly skilled engineers and technicians. These professionals can provide valuable insights during the mold design phase, ensuring that the mold is not only functional but also cost - effective to produce. They can also troubleshoot any issues that arise during the production process more efficiently. For instance, they might be able to identify and fix a problem with the mold's cooling system, which could otherwise lead to longer production times and lower - quality products.

Quality Assurance

Quality assurance is non - negotiable when choosing a mold company. First and foremost, the materials used by the company matter a great deal. High - quality steel is essential for the mold's durability, as it needs to withstand the high pressures and temperatures during the injection molding process. Some top - tier mold companies in China source their steel from well - known international suppliers, ensuring the highest standards of material quality.

In addition to materials, a rigorous quality control process is in place. This typically includes multiple inspection points throughout the mold manufacturing process. For example, after the mold components are machined, they are inspected for dimensional accuracy using precision measuring equipment like coordinate measuring machines (CMMs). During the assembly of the mold, another inspection is carried out to ensure that all parts fit together correctly. Once the mold is complete, it undergoes a final inspection and is often tested with sample production runs. The company should also have a clear set of quality standards that they adhere to, such as ISO 9001, which provides a framework for quality management systems.

Cost - effectiveness

Cost is an important factor, but it should not be the sole determinant when choosing a mold company. Different China mold companies may offer a wide range of prices for similar projects. For example, a smaller, less - established company might offer a lower initial price, but this could come at the cost of quality. They may use cheaper materials or have less - efficient production processes, which could lead to more frequent mold repairs, longer production times, and ultimately, higher costs in the long run.

On the other hand, larger, more reputable companies may have higher upfront costs, but they often provide better value for money. Their economies of scale may allow them to source materials at a lower cost, and their advanced production technologies can lead to shorter production cycles and higher - quality products. It's important to look at the total cost of ownership, including factors like maintenance, repair, and the cost of any potential production delays due to mold - related issues. A study showed that on average, choosing a higher - quality mold from a reliable company could save up to 20% in overall production costs over the life cycle of the mold compared to a cheaper, lower - quality alternative.

Production Capacity and Lead Time

The production capacity of a mold company is crucial, especially if you have a large - scale project or tight deadlines. A company with a large number of high - precision machining centers, injection molding machines, and a skilled workforce can handle larger orders more efficiently. For example, a company with 50 injection molding machines can produce more parts in a given time compared to a company with only 10 machines.

Lead time is also a significant consideration. If you need your plastic injection - molded products to be on the market quickly, you'll want a mold company that can deliver the molds in a timely manner. Some companies in China are known for their fast turnaround times, often completing projects in 4 - 6 weeks for standard molds, while others may take 8 - 12 weeks. It's essential to discuss your project timeline with the mold company upfront and ensure that they can meet your needs. If they have a backlog of orders, it could delay your project, so it's important to choose a company that can manage your order efficiently.

Communication and Customer Service

Good communication is the key to a successful project. A China mold company that communicates effectively can ensure that your requirements are clearly understood. They should be responsive to your inquiries, whether it's about the mold design, production progress, or any issues that arise during the project. For example, if you have a question about the estimated delivery date of the mold, they should be able to provide you with a timely and accurate answer.

Customer service also plays a vital role. A company that values its customers will go the extra mile to ensure your satisfaction. This may include providing after - sales support, such as helping you with any mold - related problems that occur during production, offering advice on optimizing the injection molding process, or providing spare parts in a timely manner. A company with a dedicated customer service team can make the entire project - management process much smoother and less stressful for you.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology understands the significance of choosing the right China mold company. We take pride in our expertise in handling unique projects that require customized solutions.

In terms of materials, we source only the highest - quality plastics and metals. Our in - depth knowledge of material properties allows us to recommend the most suitable options for different applications. For example, when dealing with products that need to withstand high temperatures, we might suggest using specialty plastics like PEEK.

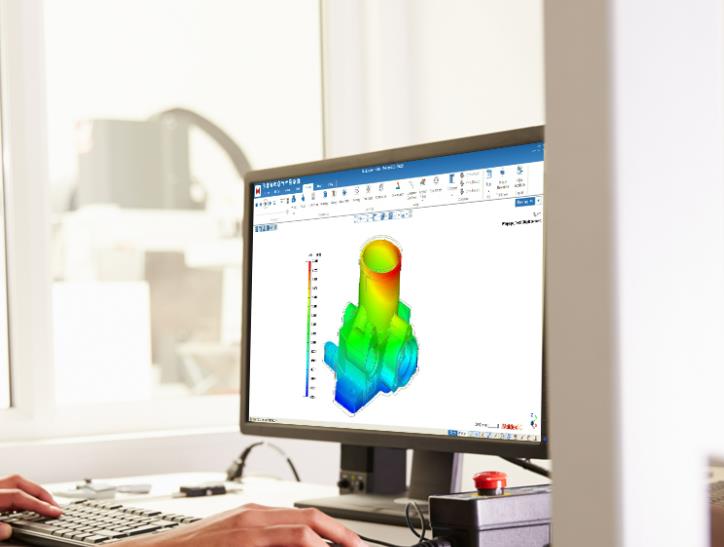

Our technical capabilities are also a strong point. We have a team of skilled engineers proficient in the latest design and manufacturing technologies. Our use of advanced CAD/CAM software enables us to create highly precise mold designs, ensuring that every product meets or exceeds our clients' expectations.

Moreover, we prioritize customer service. From the initial consultation to after - sales support, we maintain open lines of communication with our clients. We are always ready to address any concerns, provide regular project updates, and offer solutions to any issues that may arise during the production process. We believe that this comprehensive approach sets us apart in the industry and helps our clients achieve success in their plastic injection molding projects.

FAQ

Q1: How can I be sure of the quality of molds from a Chinese company?

To ensure the quality of molds from a Chinese company, first, check their quality certifications such as ISO 9001. These certifications indicate that the company follows international quality - management standards. Second, look at customer reviews and testimonials. Past clients' experiences can give you a clear picture of the mold quality. For example, if many customers praise the long - lasting and precise molds they received, it's a good sign. Third, ask to see their past project cases. By examining the molds they've produced before, you can assess the quality and craftsmanship.

Q2: What if I have a small - scale plastic injection molding project? Can I still find a suitable Chinese mold company?

Yes, even if you have a small - scale project, you can find a suitable Chinese mold company. Some companies specialize in serving small - scale clients. These companies often have lower minimum order quantities. They also tend to be more flexible in terms of project requirements. For instance, they may be willing to work on a single - mold order or provide customized solutions for your small - scale production needs. They usually have a shorter production lead time for small projects, which can be beneficial when you need the molds quickly.

Q3: How do I handle communication issues when working with a Chinese mold company?

To handle communication issues, you can use professional translation services if there is a language barrier. Another option is to choose a Chinese mold company that has a team with good English - communication skills. Many modern Chinese mold companies have English - speaking sales representatives and project managers. You can also use communication tools like video conferencing, which allow for real - time face - to - face interaction. Additionally, clearly document all your requirements in writing and ask the company to confirm their understanding to avoid misunderstandings.