Introduction

Definition and Significance

In the dynamic realm of modern manufacturing, rapid prototyping factories have emerged as pivotal players. But what exactly are they? A rapid prototyping factory is a specialized facility that employs advanced technologies to quickly transform a design concept into a physical prototype. This process, often referred to as rapid prototyping (RP), is a departure from traditional prototyping methods which can be time - consuming and costly.

The significance of rapid prototyping factories in the product development process cannot be overstated. In the past, developing a prototype could take months or even years. For instance, in the automotive industry, before the advent of rapid prototyping, creating a new car prototype involved painstaking manual labor, from hand - crafting clay models to fabricating parts through complex machining processes. This not only ate up a substantial amount of time but also required a large investment.

Today, rapid prototyping factories can cut down this time significantly. They can produce a prototype in a matter of days or weeks. This speed is crucial as it allows companies to quickly test their ideas, gather feedback, and make improvements. It shortens the overall product development cycle, enabling businesses to bring their products to market faster. In a highly competitive global market, being the first to introduce a new product can give a company a significant edge. For example, a tech startup developing a new smart device can use a rapid prototyping factory to quickly create a working prototype. This prototype can then be shown to investors, potential customers, and partners, helping the startup to gain early support and market traction.

Types of Rapid Prototyping Technologies

3D Printing

3D printing, also known as additive manufacturing, is a staple in rapid prototyping factories. It operates on the principle of building objects layer by layer from a digital model. The materials used in 3D printing are diverse. For plastics, materials like ABS (Acrylonitrile Butadiene Styrene), PLA (Polylactic Acid), and PETG (Polyethylene Terephthalate Glycol) are commonly employed. ABS is known for its strength and heat resistance, making it suitable for functional prototypes that need to withstand certain mechanical stresses and temperature variations. PLA, on the other hand, is a more environmentally friendly option, derived from renewable resources such as corn starch or sugarcane. It is often used for prototypes where environmental considerations are important, like in some consumer - product prototypes. PETG offers a good balance of strength, flexibility, and transparency, which is useful for applications where visual inspection of the prototype's internal components is necessary.

In terms of metal 3D printing, materials like aluminum, titanium, and stainless steel are utilized. Aluminum is lightweight and has good thermal conductivity, so it's great for prototypes in the aerospace and automotive industries where weight reduction and heat dissipation are crucial. Titanium is extremely strong and corrosion - resistant, making it ideal for high - performance applications such as medical implants and aerospace components. Stainless steel is widely used for its durability and resistance to rust, suitable for prototypes in industrial and consumer - product applications.

The main advantage of 3D printing in rapid prototyping is its design freedom. Complex geometries that are nearly impossible to achieve with traditional manufacturing methods can be easily printed. For example, lattice structures, which are highly efficient in terms of weight - to - strength ratio, can be 3D printed. It also enables quick iteration. A designer can make changes to the digital model and have a new prototype printed within a short time, reducing the time - to - market for products.

CNC Machining

CNC (Computer Numerical Control) machining is another important technology in rapid prototyping factories. It works by using pre - programmed computer software to control the movement of factory tools and machinery. In CNC machining, a block of raw material, which can be metal, plastic, or other materials, is gradually shaped into the desired prototype through processes like milling, turning, and drilling.

Compared to 3D printing, CNC machining generally offers higher precision and better surface finish in some cases. It is well - suited for creating prototypes with tight tolerances, such as those required in the aerospace and medical device industries. However, it is a subtractive manufacturing process, meaning it removes material from the raw block to create the final shape. This can lead to more material waste compared to 3D printing, which is an additive process. For example, if you want to create a complex - shaped prototype with a lot of internal cavities, 3D printing can build the structure layer by layer, only using the necessary amount of material. In contrast, CNC machining would have to remove a significant amount of material from the block to create those cavities.

Injection Molding for Prototyping

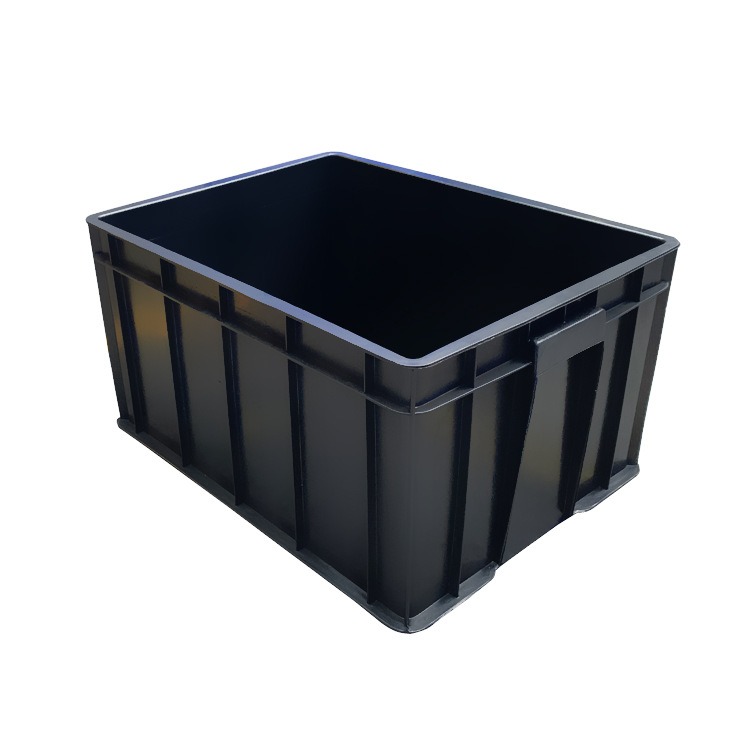

Injection molding for prototyping is a process where molten material, usually plastic, is injected into a mold cavity under high pressure. Once the material cools and solidifies, the prototype is ejected from the mold. This method is suitable for creating prototypes that closely mimic the final production parts in terms of appearance, dimensions, and mechanical properties.

It is often chosen when the prototype needs to have the same surface finish, texture, and dimensional accuracy as the mass - produced product. For example, in the consumer electronics industry, when developing a new smartphone case prototype, injection molding can be used to create a prototype that has the same smooth surface, precise fit, and color as the actual product. In terms of cost - effectiveness, injection molding can be more cost - efficient for medium - to - high - volume prototyping. Although the initial investment in mold creation is high, the cost per unit decreases as the number of prototypes increases. In comparison, 3D printing may be more cost - effective for low - volume prototyping due to its lower setup costs and no need for expensive molds.

How to Choose the Right Rapid Prototyping Factory

Experience and Expertise

When selecting a rapid prototyping factory, experience matters significantly. A factory with a long - standing presence in the industry is likely to have encountered a diverse range of projects. For example, a factory that has been in operation for over 10 years may have worked on projects across multiple industries such as automotive, aerospace, and consumer electronics. You can ask for a portfolio of their past projects. A factory that has successfully completed projects similar to yours can offer valuable insights based on their previous experiences.

Customer reviews and testimonials are also great indicators of a factory's expertise. Online platforms, industry forums, and business review sites can be good sources to find these. Positive reviews often highlight factors like on - time delivery, high - quality prototypes, and excellent customer service. For instance, if a majority of customers praise a factory for its ability to meet tight deadlines without compromising on quality, it shows that the factory has the necessary skills and resources to handle projects efficiently.

Range of Services

A good rapid prototyping factory should offer a wide range of services. In terms of material processing, it should be able to work with various materials. As mentioned before, for plastics, it should handle common types like ABS, PLA, and PETG, as well as more specialized engineering plastics if needed. In the metal category, being able to process aluminum, titanium, and stainless steel is essential. This versatility allows you to choose the most suitable material for your prototype based on its requirements.

Surface treatment services are equally important. A factory should be able to provide options such as painting, plating (e.g., chrome plating, nickel plating), anodizing (for aluminum materials), and powder coating. These surface treatments can enhance the appearance, durability, and functionality of the prototype. For example, if your prototype is a consumer product, a high - quality paint finish can make it more visually appealing.

Quality Control Measures

Quality control is the cornerstone of a reliable rapid prototyping factory. The factory should have a well - defined quality management system in place. This includes in - process inspections at various stages of the prototyping process. For example, during 3D printing, the operator may perform layer - by - layer inspections to ensure that the printing process is proceeding as expected and that there are no defects such as gaps, over - extrusion, or under - extrusion.

Common quality inspection methods include dimensional inspection. This can be done using tools like coordinate measuring machines (CMMs). A CMM can precisely measure the dimensions of the prototype and compare them to the design specifications. Any deviations outside the acceptable tolerance range can be identified and corrected. Visual inspections are also crucial. Trained inspectors carefully examine the prototype for surface defects, such as scratches, burrs, or uneven finishes. In some cases, non - destructive testing methods like X - ray inspection may be used to check for internal defects in the prototype, especially for parts where internal integrity is critical, such as aerospace components.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology has had extensive cooperation with rapid prototyping factories. Our experience has shown that such factories play a crucial role in the product development cycle.

The close cooperation between us and rapid prototyping factories is based on complementary advantages. Yigu Technology has in - depth knowledge of non - standard product requirements and a strong understanding of materials and manufacturing processes. Rapid prototyping factories, on the other hand, possess advanced equipment and expertise in quickly translating design concepts into physical prototypes.

This synergy allows us to provide our customers with high - quality prototypes in a short time. For example, when developing a complex non - standard plastic part for a special - purpose machine, the rapid prototyping factory we cooperated with used 3D printing technology to quickly create a prototype according to our design drawings. We could then test the form, fit, and function of the part, and based on the results, make improvements to the design. This iterative process, made possible by the cooperation with the rapid prototyping factory, significantly reduced the development time and cost of the final product.

FAQ

What is the typical turnaround time for a prototype?

The typical turnaround time for a prototype in rapid prototyping factories can vary significantly. For relatively simple prototypes made through 3D printing, it can be as short as 1 - 3 days. For example, a small plastic part with a straightforward geometry, like a simple phone stand prototype, can often be printed and finished within a day if the factory has the necessary materials in stock and the 3D printer is not heavily occupied.

However, for more complex prototypes or those involving multiple processes, the time can be longer. CNC - machined prototypes, especially if they require complex milling operations and tight tolerances, may take 5 - 10 days. Factors such as the complexity of the design, the availability of materials, and the workload of the factory all play a role. If a prototype requires a specialized material that needs to be sourced, it can add several days to the production time. Also, if the factory is currently handling a large number of projects, the production of your prototype may be queued, further extending the turnaround time.

Can rapid prototyping factories handle large - scale production?

Rapid prototyping factories are primarily designed for creating prototypes quickly. While some can handle limited - scale production, they have certain limitations when it comes to large - scale production. In terms of 3D printing, the speed of production per unit is generally slow compared to traditional mass - production methods like injection molding. For example, a 3D printer might produce one small part every few hours, while an injection - molding machine can produce dozens or even hundreds of the same part in an hour.

CNC machining is also not as efficient for large - scale production due to its subtractive nature, which leads to more material waste and longer processing times per part. However, rapid prototyping factories can be useful for pre - production runs. They can produce a small batch of parts (usually in the range of dozens to a few hundred) to test the market, finalize the design, or for initial product launches. But for high - volume production in the thousands or more, dedicated mass - production facilities are usually a better choice as they can achieve economies of scale, reduce production costs per unit, and increase the overall production speed.

How accurate are the prototypes produced?

The accuracy of prototypes produced in rapid prototyping factories depends on the technology used. In 3D printing, the accuracy typically ranges from ±0.1 - 0.5 mm for most common desktop and industrial 3D printers. For example, in FDM (Fused Deposition Modeling) 3D printing, which is widely used for prototyping, the layer thickness can be set as low as 0.1 mm, and the overall dimensional accuracy is often within ±0.2 - 0.3 mm for well - calibrated printers.

CNC machining generally offers higher accuracy, with tolerances as tight as ±0.01 - 0.05 mm. This makes it suitable for applications where high precision is crucial, such as in aerospace or medical device prototyping. To ensure accuracy, rapid prototyping factories use various methods. They regularly calibrate their equipment, both 3D printers and CNC machines. Quality control measures like in - process inspections and post - production dimensional checks using tools such as coordinate measuring machines (CMMs) help to verify and maintain the accuracy of the prototypes.