The Basics of 3D Printing for Aircraft Parts

How 3D Printing Works in Aircraft Parts Production

3D printing, also known as additive manufacturing, is a process that creates three - dimensional objects by adding material layer by layer. When it comes to aircraft parts production, the process starts with a digital 3D model of the part, which is typically created using Computer - Aided Design (CAD) software. This model serves as the blueprint for the 3D printer.

Once the model is ready, it is sliced into thin cross - sectional layers by specialized software. Each layer represents a thin slice of the final part. The 3D printer then reads the sliced data and starts the printing process.

During printing, the printer deposits the material in precise patterns, following the instructions from the sliced model. For example, in the case of a plastic - based 3D printing technology for aircraft interior components, a heated nozzle extrudes melted plastic filament layer by layer. As each layer is deposited, it bonds with the previous one, gradually building up the three - dimensional structure of the aircraft part. Once all the layers are printed, the part is removed from the printer, and any remaining support structures (if used) are removed, resulting in a finished aircraft part.

Common 3D Printing Technologies Used in Aviation

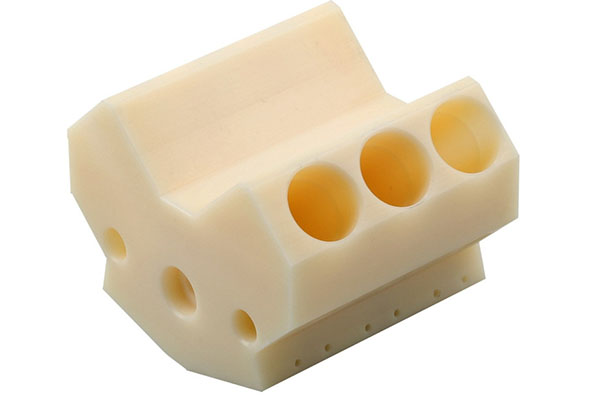

- Fused Deposition Modeling (FDM): This is one of the most well - known 3D printing technologies. FDM works by melting a thermoplastic filament, such as ABS (Acrylonitrile Butadiene Styrene) or PLA (Polylactic Acid), and extruding it through a nozzle. The nozzle moves in a precise pattern, depositing the melted material layer by layer. FDM is relatively inexpensive and can be used to create large - scale parts. It is often used for creating prototypes and non - critical aircraft interior components due to its relatively low precision and surface finish. However, its advantage lies in its ability to use a variety of materials, including some high - performance engineering plastics.

- Stereolithography (SLA): SLA uses a laser to cure a photosensitive resin layer by layer. A vat of liquid resin is exposed to a focused ultraviolet (UV) laser beam. The laser traces the cross - sectional shape of each layer on the surface of the resin, causing it to solidify. After one layer is completed, the build platform is lowered slightly, and a new layer of resin is applied and cured. SLA offers high precision and smooth surface finishes, making it suitable for creating complex and detailed aircraft parts, such as small engine components or intricate brackets. But it has limitations in terms of the types of materials available and the cost of both the equipment and the resin.

- Selective Laser Sintering (SLS): SLS uses a high - power laser to sinter powdered materials, such as nylon, metal powders, or ceramic powders. The powder is spread evenly across a build platform, and the laser selectively heats and fuses the powder particles together according to the cross - sectional shape of each layer. SLS has the advantage of not requiring support structures as the unsintered powder supports the part during the printing process. It can produce parts with good mechanical properties and is often used for manufacturing functional aircraft parts, including some metal components like engine parts or structural elements. However, the equipment is expensive, and the post - processing may be complex to remove the excess powder.

Materials for 3D Printing Aircraft Parts

Metal Materials

- Aluminum Alloys: Aluminum alloys are widely used in 3D printing of aircraft parts due to their low density, high strength - to - weight ratio, and good corrosion resistance. For example, the AlSi10Mg alloy is a popular choice. It has excellent fluidity during the 3D printing process, which allows for the creation of complex - shaped parts with high precision. In a study by [research institution], parts made from AlSi10Mg using selective laser melting (SLM) technology showed a tensile strength of up to 300 MPa and an elongation of about 8%, making it suitable for applications such as aircraft engine brackets and wing components. Another alloy, Al2139, is known for its high strength and is often used in critical aircraft structural components. It can withstand high - stress environments during flight, contributing to the overall safety and reliability of the aircraft.

- Titanium Alloys: Titanium alloys, like Ti - 6Al - 4V, are highly valued in the aerospace industry for their outstanding strength, low density, and excellent corrosion resistance, especially in high - temperature and corrosive environments. They are often used in the manufacturing of aircraft engine components, such as compressor blades and turbine disks. A 3D - printed Ti - 6Al - 4V compressor blade can reduce weight by up to 30% compared to a traditionally - manufactured one, while maintaining the same or even better mechanical properties. According to industry data, in modern aircraft engines, up to 25% of the components are made of titanium alloys, and 3D printing is enabling more complex and efficient designs of these components.

- Nickel - based Superalloys: Nickel - based superalloys, such as Inconel 625 and Inconel 718, are renowned for their excellent high - temperature strength, creep resistance, and corrosion resistance. They are crucial for applications in aircraft engines where components are exposed to extreme temperatures and mechanical stresses. Inconel 718, for instance, can maintain its mechanical properties at temperatures up to 650°C. 3D - printed Inconel 718 components, like combustion chamber liners, can be designed with internal cooling channels that are difficult to achieve through traditional manufacturing methods, enhancing the engine's efficiency and performance.

Polymer Materials

- Polyetherimide (PEI): PEI is a high - performance thermoplastic polymer with excellent mechanical properties, high heat resistance, and good flame retardancy. In aircraft interior applications, PEI is often used to 3D - print non - structural components such as air ducts, brackets, and interior panels. It can withstand the high - temperature and high - humidity environments inside the aircraft cabin. For example, 3D - printed PEI air ducts can be customized to fit specific aircraft models precisely, improving air circulation efficiency. A study showed that PEI - based 3D - printed parts can reduce the weight of interior components by 20 - 30% compared to traditional materials, while meeting all the necessary safety and performance standards.

- Polyamide (PA): Also known as nylon, polyamide is a commonly used polymer in 3D printing. It has good mechanical strength, wear resistance, and chemical resistance. PA is often used for manufacturing small non - structural aircraft parts, such as connectors, fasteners, and some decorative elements. 3D - printed PA fasteners can be produced in various shapes and sizes to meet different assembly requirements, and they are more cost - effective than their metal counterparts in some cases. Additionally, PA can be easily combined with other materials, such as carbon fibers, to enhance its mechanical properties for more demanding applications.

Composite Materials

- Carbon Fiber - Reinforced Polymers (CFRPs): CFRPs are a combination of carbon fibers and a polymer matrix, usually epoxy resin. They offer an exceptional strength - to - weight ratio, high stiffness, and good fatigue resistance. In the aerospace industry, CFRPs are used for manufacturing large - scale aircraft components like wings, fuselage sections, and empennages. 3D printing of CFRPs allows for the creation of complex internal structures that can optimize the component's performance. For example, a 3D - printed CFRP wing section can be designed with a lattice - like internal structure, reducing weight by up to 40% while maintaining the required strength and stiffness. This not only improves the aircraft's fuel efficiency but also enhances its maneuverability.

- Glass Fiber - Reinforced Polymers (GFRPs): GFRPs consist of glass fibers embedded in a polymer matrix. They are less expensive than CFRPs and still offer good mechanical properties, making them suitable for some non - critical aircraft components. GFRPs are often used in 3D - printed parts such as fairings, interior partitions, and some secondary structural elements. A 3D - printed GFRP fairing can be produced with a smooth surface finish, reducing aerodynamic drag. It also provides protection to underlying components from environmental factors, and its relatively low cost makes it an attractive option for mass - produced aircraft components.

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom Supplier, Yigu Technology believes that 3D printing technology brings unprecedented opportunities for customized production in the aviation industry. With its flexibility in design and production, 3D printing enables us to quickly respond to the unique requirements of aircraft part manufacturing. We are committed to closely following the trend of 3D printing technology development. By leveraging the advantages of this technology, such as reducing material waste and shortening production cycles, we aim to provide more high - quality and innovative products and services for the aerospace field. We look forward to contributing to the development of the aviation industry with our professional capabilities in non - standard product customization and 3D printing technology applications.

FAQs

What are the most common 3D printing materials for aircraft parts?

The most common 3D printing materials for aircraft parts include metals like aluminum alloys (such as AlSi10Mg and Al2139), titanium alloys (e.g., Ti - 6Al - 4V), and nickel - based superalloys (like Inconel 625 and Inconel 718). Among polymers, polyetherimide (PEI) and polyamide (nylon) are frequently used. Composite materials such as carbon fiber - reinforced polymers (CFRPs) and glass fiber - reinforced polymers (GFRPs) are also popular for specific aircraft components. Each material has its unique properties that make it suitable for different aircraft part applications, considering factors like strength, weight, heat resistance, and cost.

Is 3D printed aircraft parts as reliable as traditionally manufactured ones?

With the continuous development of 3D printing technology, the reliability of 3D - printed aircraft parts is increasingly comparable to traditionally manufactured ones. In the past, concerns about the internal structure and mechanical properties of 3D - printed parts led to doubts about their reliability. However, modern 3D printing techniques can precisely control the material deposition and the internal structure of the parts. For example, in the case of metal 3D printing, the use of high - energy lasers in processes like selective laser melting (SLM) can create a dense and uniform microstructure. Many 3D - printed parts have passed rigorous testing, including fatigue testing, tensile testing, and stress analysis, meeting or even exceeding the performance standards of traditional manufacturing methods in some aspects. As the technology matures, 3D - printed aircraft parts are becoming an equally reliable option for the aerospace industry.

How much can 3D printing reduce the production cost of aircraft parts?

The cost reduction achieved by 3D printing in aircraft part production varies depending on the part complexity, production volume, and material used. For small - batch production and prototype manufacturing, 3D printing can significantly reduce costs. In some cases, it can cut production costs by 30 - 50% compared to traditional manufacturing methods. For instance, when producing small non - structural parts like brackets or connectors, 3D printing can eliminate the need for expensive molds and complex machining processes. In the case of large - scale production, although the cost - reduction percentage may be lower, 3D printing can still bring cost savings through material optimization and design improvements. For example, by reducing the weight of components, it can lead to long - term cost savings in terms of fuel consumption during the aircraft's operation.