Introduction to 3D Printing in Architecture

3D printing has emerged as a groundbreaking tool in architecture, enabling the production of precise, intricate models that would be labor-intensive or impossible to achieve through traditional methods. By leveraging additive manufacturing, architects can push creative boundaries, visualize designs with unprecedented accuracy, and streamline workflows, reshaping how architectural models are conceptualized and constructed.

Overview of 3D Printing Technology

3D Printing Basics

3D printing, or additive manufacturing, creates objects by depositing material layer by layer from a digital CAD file. The process is highly versatile, allowing architects to turn complex designs into tangible models efficiently.

Key Technologies in Architectural Applications:

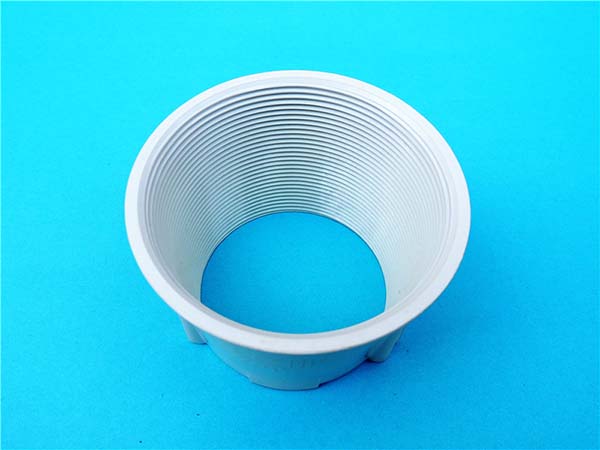

- Fused Deposition Modeling (FDM): Ideal for cost-effective, durable models using thermoplastics.

- Stereolithography (SLA): Excels in creating smooth, detailed models with resin, perfect for intricate architectural designs.

- Selective Laser Sintering (SLS): Uses laser technology to fuse powdered material, enabling the creation of complex structures without support materials.

Benefits of 3D Printing for Architectural Models

Enhanced Precision and Detail

3D printers translate intricate digital designs into precise physical models with fine details, reducing errors associated with manual model-making and ensuring fidelity to the original design.

Facilitating Complex Geometric Designs

The technology accommodates unconventional forms, such as organic shapes and detailed facades, unachievable with traditional techniques. This freedom fosters greater creativity and experimentation.

Time and Cost Efficiency

3D printing drastically reduces the time needed to produce models and minimizes material wastage, leading to significant cost savings—especially for iterative prototyping.

Sustainability

Architects can print models using only the required material, significantly reducing waste. Many 3D printing materials are recyclable, aligning with sustainability goals.

Case Studies and Examples

Notable Projects

- Casa Batlló: Architects used 3D printing to create detailed models of Antoni Gaudí’s masterpiece, capturing its intricate, curvilinear designs.

- Zaha Hadid Architects: This firm uses 3D printing to prototype innovative, fluid structures, demonstrating the technology’s potential for dynamic architectural designs.

Comparison with Traditional Modeling

| Feature | Traditional Modeling | 3D Printing |

|---|---|---|

| Precision | Dependent on manual skill | High and consistent |

| Complexity | Limited by tools and labor | Unlimited geometric possibilities |

| Cost and Time | Higher due to labor intensity | Lower with faster production |

| Material Use | More wasteful | Material-efficient |

The Impact of 3D Printing on Architectural Design

3D printing not only enhances the model-making process but also transforms architectural design philosophies. By enabling quick iteration and detailed visualization, architects can explore bolder concepts and refine designs with greater confidence. This iterative capability bridges the gap between digital design and physical reality, fostering innovative architectural solutions.

Conclusion

3D printing is revolutionizing architectural model-making by offering unparalleled precision, efficiency, and design freedom. The technology has streamlined workflows, reduced costs, and opened new avenues for creative expression. As 3D printing continues to evolve, its role in architecture is poised to expand further, shaping the future of design and construction.

FAQs

1. What is 3D printing in architecture?

3D printing in architecture involves creating detailed physical models of structures using additive manufacturing technologies, based on digital CAD designs.

2. How does 3D printing benefit architectural model-making?

It enhances precision, supports complex geometries, saves time and cost, and aligns with sustainability efforts by reducing material waste.

3. Can 3D printing be used for full-scale construction?

Yes, full-scale 3D printing is already being used to construct entire buildings, offering reduced labor costs, faster timelines, and customizable designs.