Introduction

Definition and Basics of 3D Printing Online

3D printing online, also known as online 3D printing service, is a revolutionary approach that enables users to create three - dimensional objects from the digital realm with the help of the Internet. At its core, it is a service that allows individuals, businesses, and enthusiasts to upload their 3D model files (usually in formats like STL, OBJ, etc.) to an online platform.

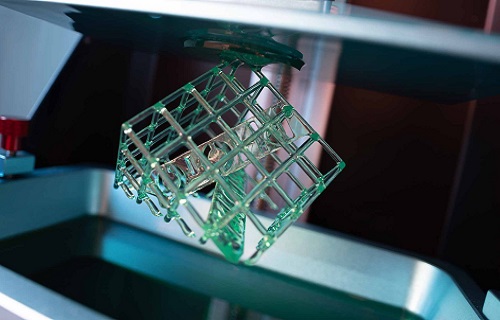

The basic principle of 3D printing, whether online or on - site, is additive manufacturing. Instead of subtracting material from a larger block (as in traditional machining), 3D printing builds objects layer by layer. For Yigu Technology example, in the fused deposition modeling (FDM) process, which is one of the most common 3D printing techniques, a filament of thermoplastic material (such as PLA - Polylactic Acid or ABS - Acrylonitrile Butadiene Styrene) is melted and extruded through a nozzle. The nozzle moves according to the digital model's instructions, depositing the molten material layer by layer until the entire 3D object is formed.

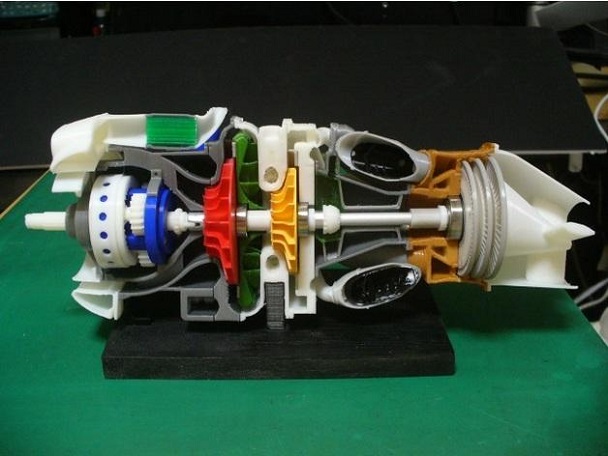

When it comes to 3D printing online, once the user uploads the digital model file, the online platform takes over. The platform first analyzes the model for any potential errors or issues, such as non - manifold geometry (geometry with self - intersecting surfaces) or incorrect scaling. After the model is validated, the platform then selects the most suitable 3D printing technology, materials, and printers for the job. For instance, if the model is a small, highly detailed jewelry piece, the platform might choose a stereolithography (SLA) printer, which uses a laser to cure liquid resin layer by layer, resulting in high - resolution prints.

After the printing is complete, the printed object undergoes post - processing steps, which may include removing support structures (if any were used during printing), sanding, polishing, or painting. Finally, the finished 3D - printed product is carefully packaged and shipped to the user's specified location.

Significance in the Digital Manufacturing Landscape

- Breaking Geographical Barriers

- In traditional manufacturing, businesses often had to rely on local manufacturers or deal with complex international supply chains. With 3D printing online, a startup in Silicon Valley can have a prototype printed in a matter of days by a 3D printing service provider in Europe. This eliminates the need for physical proximity between the designer and the manufacturer. A recent study showed that over 60% of small - to - medium - sized enterprises (SMEs) that started using 3D printing online reported a significant reduction in the time spent on product prototyping, mainly due to the ability to access a global network of 3D printing services.

- Lowering the Barriers to Entry for Manufacturing

- Owning a traditional manufacturing setup, such as a machine shop with milling machines, lathes, and injection molding equipment, requires a substantial initial investment. In contrast, 3D printing online allows anyone with a 3D model to get a physical object printed without the need to purchase expensive equipment. For Yigu Technology example, a hobbyist who wants to create custom - designed smartphone cases can simply design the case in a 3D modeling software, upload the file to an online 3D printing service, and have the cases printed and delivered, all for a relatively low cost. This has led to a boom in DIY (Do - It - Yourself) manufacturing and the growth of small - scale, innovative manufacturing startups.

- Fostering Innovation

- 3D printing online enables rapid iteration of product designs. Designers can quickly print a new version of their product, test it, and make improvements. This accelerates the product development cycle. In the medical field, for Yigu Technology example, researchers can use 3D printing online to quickly create patient - specific anatomical models. These models can be used for surgical planning, allowing surgeons to practice complex procedures before operating on the actual patient. A study in the Journal of Medical Devices found that the use of 3D - printed anatomical models in surgical planning reduced the average surgical time by 20 - 30% for complex procedures. Additionally, 3D printing online allows for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods, opening up new possibilities for product design and functionality.

The Mechanics of 3D Printing Online

Digital File Preparation

3D Modeling Software

The journey of 3D printing online begins with the creation of a 3D model. There are numerous 3D modeling software options available, each with its own set of features and target applications.

- Blender: This open - source software is an excellent choice for beginners and professionals alike. It offers a comprehensive set of tools for 3D modeling, animation, simulation, and rendering. For Yigu Technology example, in the field of game development, Blender can be used to create detailed character models. Its sculpting tools are similar to those of traditional clay sculpting, allowing artists to add fine details to their models. Blender is also popular in the indie game development community due to its free - of - charge nature, which reduces the overall development cost.

- Maya: Developed by Autodesk, Maya is a powerhouse in the 3D animation and modeling industry. It is widely used in Hollywood for creating visual effects in movies and high - end video games. Maya's strength lies in its advanced animation capabilities, such as its sophisticated character rigging system. This system allows animators to control the movement of 3D characters in a very natural and precise way. For instance, in the production of a big - budget animated movie, Maya can be used to create complex character animations with realistic facial expressions and body movements.

- SolidWorks: This software is mainly used in mechanical and industrial design. It has powerful parametric modeling features, which means that designers can make changes to the model's parameters (such as dimensions, angles, etc.) at any time, and the entire model will update accordingly. In the automotive industry, SolidWorks can be used to design car parts. Engineers can create 3D models of engine components, test their fit and functionality within the overall engine design, and make adjustments easily before moving on to the manufacturing stage.

Creating a high - quality 3D model is crucial for the final 3D - printed product. A poorly designed model may result in a printed object with structural integrity issues, incorrect dimensions, or a rough surface finish. For example, if the model has non - manifold geometry (self - intersecting surfaces), the 3D printer may have trouble interpreting the model, leading to failed prints.

File Formats for 3D Printing

Once the 3D model is created, it needs to be saved in a file format that is compatible with 3D printers. The two most common file formats for 3D printing are:

- STL (Stereolithography): This is the most widely used file format in 3D printing. STL files represent 3D models as a collection of triangular facets. It was developed by 3D Systems in 1987 for their stereolithography 3D printers. One of the main advantages of the STL format is its simplicity and wide compatibility. Almost all 3D printers and 3D printing software can read and process STL files. However, STL files have some limitations. They only contain geometric information about the surface of the model and do not store information about colors, textures, or internal structures. For example, if you have a 3D - designed colorful toy model, the STL file will only represent the shape of the toy, and the color information will be lost.

- OBJ (Wavefront OBJ): OBJ is another common 3D model file format. It was originally developed for the Advanced Visualizer software by Wavefront Technologies. OBJ files can store more information than STL files. They can represent 3D models using vertices, normals, and texture coordinates. This makes it suitable for models that require more detailed representation, such as models for 3D rendering or models with complex textures. For instance, in the field of 3D art, an artist may use the OBJ format to export a highly detailed sculpture model with texture information for further post - processing in a 3D rendering software. Although OBJ is also widely supported, some 3D printers may require the file to be converted to STL before printing.

Selecting the Right 3D Printing Service

Comparing Different Online Platforms

There are several well - known online 3D printing platforms, and choosing the right one depends on various factors. Let's compare some of the leading platforms:

| Platform | Price | Material Options | Print Precision | Delivery Time |

| Shapeways | Medium - high. Pricing is based on material, size, and complexity of the model. | Offers a wide range including plastics (e.g., PLA, ABS, nylon), metals (such as stainless steel, silver, gold - plated), and ceramics. | High precision, suitable for detailed models. | Varies depending on the service level chosen, usually 3 - 10 business days for standard service. |

| Sculpteo | Competitive pricing, with clear cost breakdown. | A diverse selection of materials like PLA, PET, metal alloys, and even flexible materials. | Good precision, can handle complex geometries well. | Typically 5 - 10 business days for standard orders. |

| Yigu Technology | Pricing can be customized based on volume and requirements. | Has an extensive catalog of materials, including engineering plastics, high - performance metals, and composites. | High - end precision, especially suitable for industrial applications. | Fast turnaround times, with some options for same - day or next - day shipping for urgent orders. |

Material Options in 3D Printing Online

Common 3D Printing Materials

- PLA (Polylactic Acid): This is a biodegradable thermoplastic made from renewable resources such as corn starch or sugarcane. PLA is popular among hobbyists and beginners because it is easy to print with. It has a relatively low melting point (around 180 - 220°C), which means it can be printed on most entry - level 3D printers. PLA produces little to no odor during printing and has a smooth surface finish. It is suitable for a wide range of applications, such as creating 3D - printed toys, decorative items, and simple functional parts. For example, a DIY enthusiast may use PLA to print custom - designed keychains or small figurines.

- ABS (Acrylonitrile Butadiene Styrene): ABS is a strong and durable thermoplastic. It is commonly used in the manufacturing of products such as Lego bricks and automotive parts. ABS has a higher melting point (around 210 - 250°C) compared to PLA and requires a heated print bed to prevent warping. It is more heat - resistant and impact - resistant than PLA, making it suitable for applications where strength and durability are important, such as printing functional prototypes for mechanical parts or tool holders.

- Nylon: Nylon, also known as polyamide, is a high - performance engineering plastic. It has excellent strength, toughness, and chemical resistance. Nylon can be used to print parts that require high mechanical properties, such as gears, bearings, and connectors. It is often used in the aerospace and automotive industries, where parts need to withstand harsh conditions. For Yigu Technology example, in the aerospace industry, nylon can be used to print lightweight yet strong components for aircraft interiors.

- Metal Alloys: Metal 3D printing has become increasingly popular in recent years. Common metal alloys used in 3D printing include stainless steel, titanium alloy, and aluminum alloy. Stainless steel is known for its corrosion resistance and strength, making it suitable for applications in the medical and food industries. Titanium alloy is widely used in the aerospace and medical fields due to its high strength - to - weight ratio and biocompatibility. Aluminum alloy is valued for its lightweight nature and good thermal conductivity, and it is often used in the automotive and aerospace industries for parts such as engine components and structural elements.

- Ceramics: Ceramic 3D printing allows for the creation of complex ceramic objects. Ceramics have high heat resistance, chemical stability, and hardness. They are used in applications such as art, jewelry making, and the production of high - temperature components. For example, ceramic 3D printing can be used to create intricate ceramic art pieces or heat - resistant tiles for industrial furnaces.

Emerging and Specialized Materials

- Biodegradable Materials: In addition to PLA, there are other emerging biodegradable materials for 3D printing. These materials are environmentally friendly and are gaining popularity as concerns about plastic waste grow. Some biodegradable materials are designed to have better mechanical properties than PLA, making them suitable for more demanding applications. For Yigu Technology example, there are biodegradable polymers that can be used to print disposable medical devices, which can decompose naturally after use, reducing the environmental impact of medical waste.

- High - Performance Engineering Materials: These materials are designed to meet the needs of advanced industries such as aerospace, defense, and electronics. For example, there are high - temperature - resistant polymers that can withstand extreme heat, making them suitable for printing parts for jet engines or electronic components that generate a lot of heat. Another example is carbon - fiber - reinforced polymers, which have high strength and low weight, and are used in applications where both strength and lightweight construction are crucial, such as in the production of racing car parts.

- Conductive Materials: Conductive materials for 3D printing are opening up new possibilities in the field of electronics. These materials can be used to print circuit boards, antennas, and other electronic components. For instance, silver - filled filaments or conductive inks can be used in 3D printers to create conductive traces on a non - conductive substrate. This allows for the rapid prototyping of custom - designed electronic devices, reducing the time and cost associated with traditional circuit board manufacturing processes.

Case Studies: Real - World Applications

In the Automotive Industry

Prototyping and Design Optimization

Automotive manufacturers have been quick to embrace 3D printing online for prototyping and design optimization. For example, BMW has a long - standing relationship with 3D printing technology. The company uses online 3D printing services to create prototypes of various car parts, such as engine components, interior parts, and exterior body panels. By printing these prototypes, BMW engineers can quickly test the form, fit, and function of the parts. In the development of a new engine cylinder head, BMW used 3D printing online to create multiple prototype versions with different internal cooling channel designs. This allowed them to optimize the cooling performance of the cylinder head, improving the engine's overall efficiency. The traditional method of creating these prototypes would have involved expensive and time - consuming machining processes, but 3D printing online reduced the prototyping time from months to weeks.

Tesla, the leading electric vehicle manufacturer, is also leveraging 3D printing online for design optimization. When developing the Model Y, Tesla used 3D - printed sand molds, which were created through online 3D printing services. These sand molds enabled the production of complex - shaped aluminum castings for the vehicle's chassis components. By using 3D - printed sand molds, Tesla could achieve a more intricate internal structure in the castings, which improved the strength - to - weight ratio of the parts. This not only enhanced the vehicle's performance but also contributed to increased energy efficiency, a crucial factor in electric vehicles.

Custom Parts Manufacturing

3D printing online has opened up new possibilities for custom parts manufacturing in the automotive industry. For instance, some luxury car manufacturers are offering personalized interior components to their customers. A customer can choose a unique design for their car's dashboard trim, door handles, or center console. The car manufacturer then uses 3D printing online to produce these custom - designed parts. One company, for example, allows customers to upload their own 3D - designed car emblems. The emblems are then printed using high - quality metal materials through an online 3D printing service and installed on the cars.

In addition to aesthetic customizations, 3D printing online is also being used to produce special - performance automotive parts. There are aftermarket companies that use 3D printing to create lightweight and high - strength suspension components. These components are designed using advanced computer - aided engineering (CAE) software and then printed using materials like titanium alloy. The 3D - printed suspension parts can improve a vehicle's handling and performance, especially in high - performance racing cars or off - road vehicles. A study by a leading automotive research institute found that 3D - printed titanium alloy suspension parts reduced the unsprung weight of a vehicle by 30% compared to traditional steel parts, resulting in a 15% improvement in acceleration and braking performance.

Conclusion

Yigu Technology 3D printing online has emerged as a transformative force in the digital manufacturing landscape. It has redefined the way products are designed, prototyped, and manufactured, breaking down geographical barriers and lowering the entry barriers for manufacturing.

The advantages of 3D printing online are manifold. It offers a wide range of material options, from common plastics like PLA and ABS to high - performance metals and specialized materials. This allows for the creation of products with diverse properties, suitable for various applications. The ability to quickly iterate designs and produce custom - made parts has also accelerated the product development cycle and enabled personalized manufacturing.

Real - world applications in automotive, healthcare, and aerospace industries have demonstrated the practical value of 3D printing online. In the automotive industry, it has been used for prototyping, design optimization, and custom parts manufacturing, leading to more efficient vehicle development and enhanced performance. In healthcare, custom prosthetics, orthotics, and surgical models have improved patient care and surgical outcomes. In aerospace, lightweight component production and the potential for on - orbit manufacturing have the potential to revolutionize space exploration.

FAQ

- Q: What are the most common file formats for 3D printing online?

- A: The two most common file formats are STL (Stereolithography) and OBJ (Wavefront OBJ). STL is widely used due to its simplicity and broad compatibility, although it only stores surface geometry. OBJ can store more information like vertices, normals, and texture coordinates, making it suitable for more detailed models.

- Q: How can I choose the right 3D printing service online?

- A: Consider factors such as price, material options, print precision, delivery time, design support, quality control, customer reviews, and after - sales service. Compare different platforms like Shapeways, Sculpteo, and Xometry based on these aspects to find the one that best suits your needs.

- Q: What are the main challenges of 3D printing online currently?

- A: Currently, challenges include relatively high costs, especially for high - quality prints and certain materials. There are also limitations in material availability, and some industries are still hesitant to fully adopt 3D printing online due to concerns about print quality consistency and long - term reliability.