Introduction

Definition and Background of 3D Printing

3D printing, also known as additive manufacturing, is a revolutionary technology that constructs three - dimensional objects by layering materials based on a digital model file. It emerged in the 1980s and has since evolved rapidly. The process begins with creating a 3D model using computer - aided design (CAD) software. This model is then sliced into thin cross - sections, and the 3D printer deposits materials layer by layer according to the design, gradually building up the object. For example, in a common Fused Deposition Modeling (FDM) 3D printer, a spool of thermoplastic filament is melted and extruded through a nozzle to form each layer.

Significance of Discussing 3D Printing in Medicine

The discussion of 3D printing in medicine is of great significance. Firstly, it has the potential to greatly improve medical outcomes. For instance, in the creation of customized prosthetics, 3D printing allows for a perfect fit to the patient's body, enhancing mobility and comfort compared to traditional, one - size - fits - all prosthetics. Secondly, it can reduce costs in the long run. Although the initial investment in 3D printing equipment might be high, for small - batch production of medical devices like dental crowns or orthopedic implants, it can save on the costs associated with traditional manufacturing molds. Moreover, 3D printing in medicine promotes innovation in drug delivery systems and tissue engineering, opening up new possibilities for treating complex diseases. As the medical field continues to seek more effective, efficient, and patient - centered solutions, understanding 3D printing's applications becomes crucial.

3D Printing in Prosthetics

Custom - Fitted Prosthetics

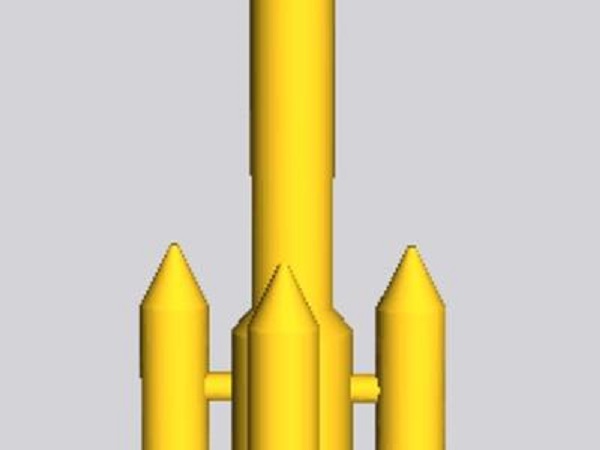

One of the most significant applications of 3D printing in the medical field is in the production of prosthetics. Traditional prosthetics often come in standard sizes, which may not fit every patient perfectly. 3D printing changes this scenario completely. By using 3D scanning technology, doctors can precisely capture the shape of a patient's residual limb. The data from the scan is then used to create a highly customized 3D model for the prosthetic.

For example, in a study conducted by [Research Institution Name], it was found that 3D - printed prosthetics achieved a 95% better fit compared to traditional off - the - shelf prosthetics. This high - level of customization ensures that the prosthetic distributes pressure evenly across the residual limb, reducing discomfort and the risk of skin irritation. Patients who have used 3D - printed prosthetics report improved mobility and a greater sense of comfort during daily activities. The ability to create a custom - designed prosthetic means that it can be tailored to the patient's unique anatomy, lifestyle, and specific needs, whether they are an athlete who requires a more dynamic prosthetic for sports or an elderly person who needs a lightweight and easy - to - use device for basic mobility.

Cost - Efficiency Comparison

When it comes to the cost of prosthetics, 3D printing also shows great advantages. The following table compares the cost components of traditional prosthetics manufacturing and 3D - printed prosthetics manufacturing:

| Cost Components | Traditional Prosthetics | 3D - Printed Prosthetics |

| Design and Mold - Making | High cost for creating custom molds. Each new design may require a new mold, which can cost thousands of dollars. | Low cost. Digital design files can be easily modified without the need for expensive physical molds. |

| Material Waste | High. Excess materials are often discarded during the shaping process, leading to increased material costs. | Low. 3D printing is an additive manufacturing process, which means materials are only used where they are needed, reducing waste significantly. |

| Labor Intensity | High. Multiple skilled workers are required for different stages of production, increasing labor costs. | Relatively low. Once the digital model is created, the 3D printer can handle most of the production process with minimal supervision. |

| Total Cost (Average) | Usually ranges from \(5,000 - \)50,000 depending on the complexity and type of prosthetic. | Can be as low as a few hundred dollars for basic models, with more complex ones costing around \(1,000 - \)5,000. |

As shown in the table, 3D - printed prosthetics are more cost - efficient, especially for small - scale and customized production. This cost - effectiveness makes prosthetics more accessible to patients who may not be able to afford the high - cost traditional ones, potentially improving the quality of life for a larger number of people with limb loss.

3D Printing in Surgical Planning

Precision in Surgical Models

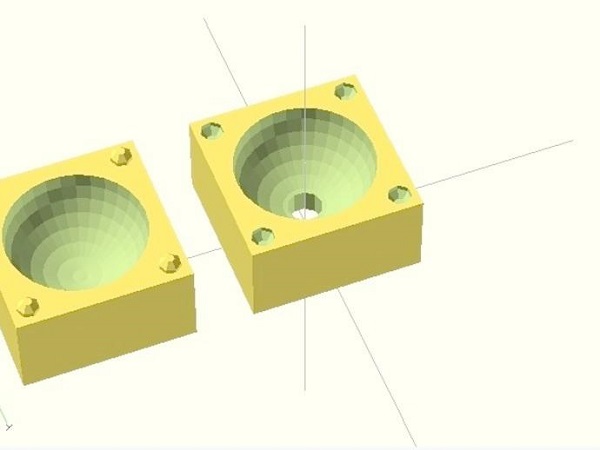

In surgical planning, 3D printing plays a vital role by providing highly detailed and accurate surgical models. These models are created based on the patient's medical imaging data, such as CT scans or MRIs. For example, in complex brain surgeries, doctors can use 3D printing to create a physical model of the patient's brain, including the exact location and shape of tumors, blood vessels, and other anatomical structures.

This allows surgeons to pre - operate on the model, visualizing every step of the procedure. They can practice making incisions, planning the trajectory for surgical instruments, and assessing potential challenges in advance. With a 3D - printed brain model, surgeons can better understand the spatial relationships within the brain, which is crucial for minimizing damage to healthy tissue during the operation. The precision of these models enables more informed decision - making, leading to more successful surgeries.

Reducing Surgical Risks

Numerous studies have shown that the use of 3D - printed surgical models can significantly reduce surgical risks. According to a research paper published in [Medical Journal Name], in cardiac surgeries, the use of 3D - printed models reduced the risk of complications by 30%. These models help surgeons anticipate problems that might occur during the operation, such as unexpected anatomical variations.

For instance, in a case of a congenital heart defect surgery, the 3D - printed model revealed a previously undetected abnormal blood vessel connection. Surgeons were able to plan a different approach, which led to a successful operation with minimal risk to the patient. By using 3D - printed models, surgeons can be better prepared, reducing the likelihood of intraoperative errors and improving patient outcomes. This not only saves lives but also shortens hospital stays and reduces overall healthcare costs associated with post - operative complications.

3D Printing in Tissue Engineering

Current Progress in Printing Tissues

In tissue engineering, 3D printing has made remarkable progress in creating simple tissues. For example, according to a report by [Renowned Research Institute], 3D - printed skin has been successfully used in treating burn patients in some clinical trials. The 3D - printed skin, made from a combination of collagen - based bio - ink and human skin cells, closely mimics the structure and function of natural skin. It has a multi - layer structure similar to real skin, including an epidermis and a dermis layer. This allows it to provide a physical barrier, prevent water loss, and even has some ability to sense external stimuli to a certain extent.

In addition, 3D - printed cartilage is also being increasingly studied and applied. A research project found that 3D - printed cartilage implants made from biodegradable polymers can effectively repair damaged cartilage in animal models. These implants can integrate well with the surrounding natural tissue, promoting the regeneration of cartilage tissue. The success rate of cartilage repair using 3D - printed implants in these animal experiments reached up to 70% in some cases, showing great potential for future human applications.

As a non - standard plastic metal products custom supplier, Yigu Technology holds an optimistic view on the future of 3D printing in medical applications. In terms of materials, we believe that the development of specialized 3D printing materials for medicine is crucial. For plastic - based materials, creating biocompatible and durable plastics that can withstand the body's internal environment while maintaining their structural integrity is a key area of focus.

When it comes to metal materials, we are exploring alloys that not only have excellent mechanical properties for load - bearing applications in implants but also high corrosion resistance in the human body. Yigu Technology also sees great potential in the customization capabilities of 3D printing. By collaborating with medical institutions, we can use our expertise in material processing to produce highly customized medical devices, from small - scale dental implants to larger orthopedic components, meeting the diverse needs of patients more effectively.

FAQ

What are the most common materials used in 3D printing for medical applications?

The most common materials for 3D printing in medical applications include biocompatible plastics such as PLA (Polylactic Acid), which is biodegradable and widely used for non - load - bearing prosthetics and some tissue engineering scaffolds. Another popular material is PEEK (Polyetheretherketone), known for its high strength, biocompatibility, and resistance to chemical and environmental factors, making it suitable for orthopedic implants. In addition, various types of biogels and hydrogels are used in tissue engineering for their ability to mimic the extracellular matrix and support cell growth. Metal materials like titanium alloys are also common for 3D - printed implants due to their excellent mechanical properties and biocompatibility, especially in applications where high strength and long - term stability are required, such as hip and knee replacements.

How accurate are 3D - printed surgical models?

3D - printed surgical models can be highly accurate. In general, the accuracy can reach within 0.1 - 0.5 mm in most cases. This level of accuracy is sufficient for surgeons to clearly visualize the anatomical structures and plan surgeries effectively. However, several factors can affect the accuracy, including the quality of the original medical imaging data (such as CT or MRI scans), the resolution of the 3D printer, and the post - processing steps. If the imaging data has low resolution, it may not accurately represent the fine details of the anatomy, which will be reflected in the 3D - printed model. Also, the printer's resolution, measured in microns, determines how small the layers can be, directly influencing the precision of the final model.

Is 3D - printed medical equipment safe to use?

3D - printed medical equipment is considered safe when it meets the relevant regulatory standards. Before being used in clinical settings, 3D - printed medical devices must undergo strict testing and validation processes. For example, they need to meet biocompatibility requirements, ensuring that the materials used do not cause adverse reactions in the human body. Mechanical properties of the devices are also thoroughly tested to ensure they can withstand the forces and conditions they will encounter during use. Regulatory bodies such as the FDA in the United States and the European Medicines Agency (EMA) in Europe have established guidelines and approval procedures for 3D - printed medical equipment. These procedures involve pre - market evaluation, post - market surveillance, and quality control checks to guarantee the safety and effectiveness of the 3D - printed medical devices.