Introduction

What is Liquid Metal 3D Printing and Why is it Gaining Traction?

Liquid metal 3D printing is an innovative additive manufacturing technology that uses liquid metal as the raw material to create three - dimensional objects layer by layer. This technology combines the unique properties of liquid metals, such as excellent electrical conductivity, high thermal conductivity, and good fluidity, with the flexibility and customization capabilities of 3D printing.

In traditional 3D printing, materials like plastics, resins, and some powdered metals are commonly used. However, liquid metal 3D printing offers a new dimension. The liquid metal can be precisely deposited and solidified in a controlled manner, enabling the production of complex geometries that are difficult to achieve with other materials. For example, some liquid metals can be printed at room temperature, which reduces the need for high - temperature processing and potential material degradation issues associated with high - temperature 3D printing processes.

This article will explore the principles behind liquid metal 3D printing, its advantages over traditional manufacturing methods, the challenges it currently faces, and its wide - ranging applications across various industries. We will also hear the insights from Yigu Technology, a non - standard plastic metal products custom supplier, on how this technology impacts their business and the future of manufacturing.

How Does Liquid Metal 3D Printing Work?

Liquid metal 3D printing typically involves several key steps. First, a digital 3D model of the object to be printed is created using computer - aided design (CAD) software. This model serves as the blueprint for the entire printing process.

The liquid metal, which is often an alloy with a low melting point such as a gallium - based alloy, is then prepared. In some cases, the metal is heated to its liquid state if it is not already in a liquid form at room temperature.

During the printing process, the liquid metal is precisely deposited layer by layer. This can be achieved through methods such as extrusion - based printing, where the liquid metal is pushed through a nozzle. The nozzle moves in a predefined path, controlled by the 3D printer's software, depositing the liquid metal in the exact shape required for each layer of the object. As the liquid metal is deposited, it solidifies rapidly, either due to cooling or chemical reactions, forming a solid layer. This process is repeated layer by layer until the entire 3D object is completed.

Compared with traditional 3D printing technologies like Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), liquid metal 3D printing has its uniqueness. FDM melts and extrudes plastic filaments, which restricts it to plastic - based materials. SLA uses ultraviolet light to cure liquid resins, mainly focusing on resin - based products. SLS sinters powdered materials using a laser. In contrast, liquid metal 3D printing can produce parts with high electrical and thermal conductivity, which is difficult to achieve with the above - mentioned traditional 3D printing methods. For example, a study showed that parts printed with liquid metal had thermal conductivity values several times higher than those printed with common 3D - printed plastics in FDM, making them ideal for applications in heat - dissipation components.

Applications of Liquid Metal 3D Printing

Liquid metal 3D printing has found its way into a wide range of industries, revolutionizing the manufacturing process with its unique capabilities.

In the Manufacturing Industry

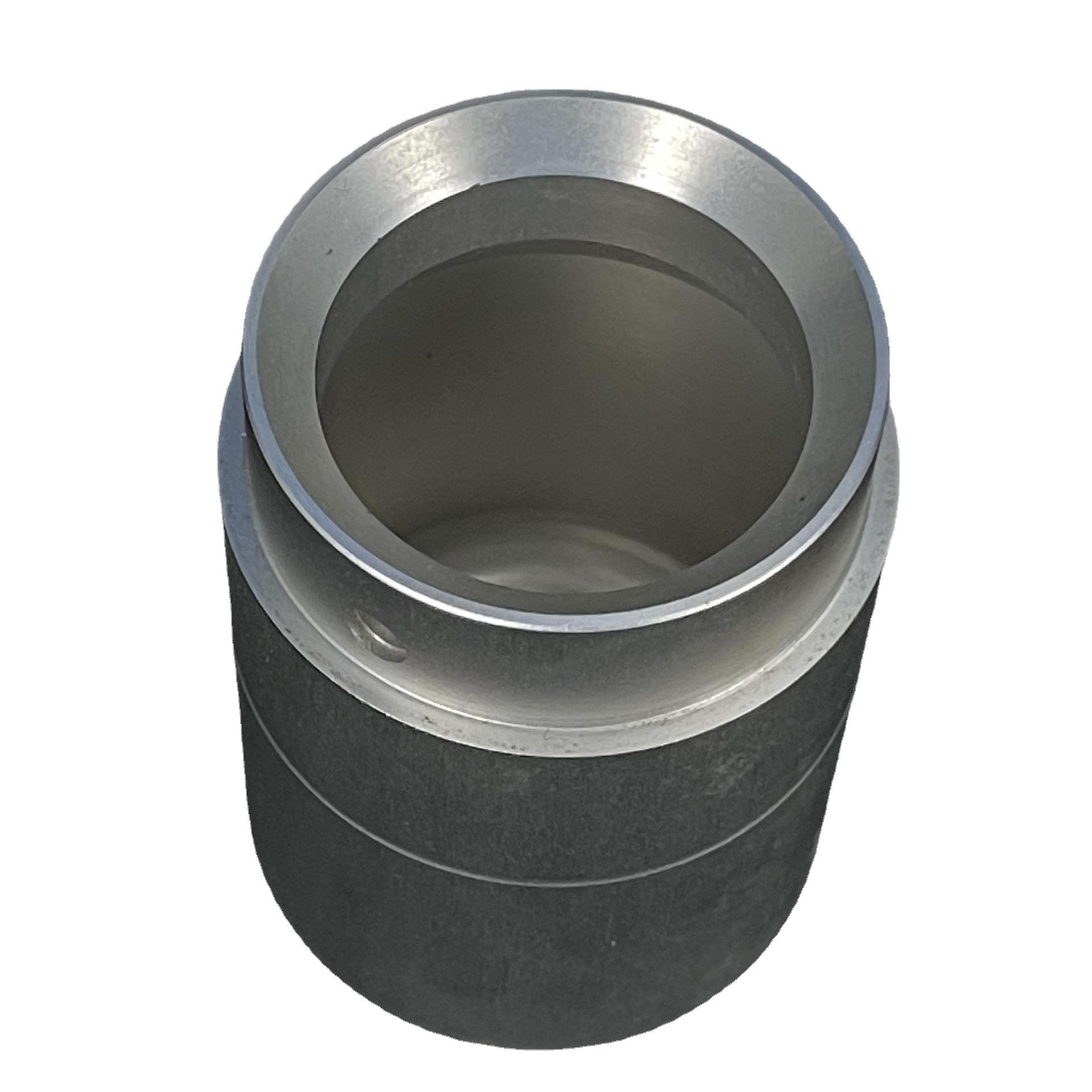

In the manufacturing industry, liquid metal 3D printing is used to produce complex - shaped components with high precision. For example, in the automotive industry, it can be used to create engine parts such as cylinder heads. Traditional manufacturing methods for cylinder heads often involve multiple complex processes like casting and machining. However, with liquid metal 3D printing, the internal cooling channels of the cylinder head can be designed and printed in a more optimized way. A study showed that 3D - printed cylinder heads with optimized internal channels could improve engine cooling efficiency by up to 20%, leading to better engine performance and fuel efficiency.

In the production of aircraft components, liquid metal 3D printing is also gaining ground. Parts like wing brackets, which require high strength - to - weight ratios, can be printed. The ability to print complex geometries allows for the creation of parts with internal structures that enhance strength while reducing weight. Compared to conventionally manufactured wing brackets, 3D - printed ones can be up to 30% lighter without sacrificing strength, as demonstrated by tests in aerospace research facilities.

In the Medical Field

The medical field has also seen remarkable applications of liquid metal 3D printing. One of the most significant is in the production of personalized prosthetics. Since each patient's body structure is unique, traditional mass - produced prosthetics often require extensive modifications to fit properly. With liquid metal 3D printing, prosthetics can be custom - printed according to a patient's exact limb shape and size. This not only improves the comfort of the prosthetics but also enhances their functionality.

In dentistry, liquid metal 3D printing can be used to create dental implants and crowns. These printed dental products can better match the patient's natural teeth in terms of shape, color, and fit. Research has shown that 3D - printed dental implants have a higher success rate of osseointegration (the process of the implant fusing with the bone) compared to some traditional implants, with a success rate increase of about 15% in clinical trials.

In the Aerospace Industry

Aerospace is another industry where liquid metal 3D printing offers great potential. Complex structural components such as fuel nozzles and turbine blades can be manufactured. Fuel nozzles in jet engines need to have precise internal channels to ensure efficient fuel spraying. Liquid metal 3D printing enables the creation of fuel nozzles with highly optimized internal channel designs, improving fuel atomization and combustion efficiency. Tests have shown that engines with 3D - printed fuel nozzles can achieve a 10 - 15% increase in fuel combustion efficiency.

Turbine blades, which operate under extremely high - temperature and high - stress conditions, can also benefit from liquid metal 3D printing. The ability to print with high - performance metal alloys allows for the production of turbine blades with enhanced heat - resistance and mechanical properties.

In the Construction Industry

In the construction industry, liquid metal 3D printing can be used to manufacture building structural components. For example, steel - based liquid metal can be printed into complex - shaped brackets and connectors. These 3D - printed components can be designed to distribute loads more effectively in buildings, enhancing the overall structural stability. In the production of building facades, liquid metal 3D printing can create unique and aesthetically pleasing patterns and textures that are difficult to achieve with traditional construction methods. Additionally, for the production of windows and doors, liquid metal 3D printing can be used to create custom - designed frames with high - precision dimensions, improving the fit and energy - efficiency of the building envelope.

Yigu Technology's View

Yigu Technology, as a non - standard plastic metal products custom supplier, highly values the potential of liquid metal 3D printing. We firmly believe that this technology represents a significant leap forward in manufacturing, offering unique advantages such as high - precision production and the ability to create complex geometries.

We are committed to leveraging liquid metal 3D printing to provide our clients with more customized and high - quality products. Our team of experts is constantly exploring new applications and materials in this field, aiming to push the boundaries of what's possible. We understand that each client's needs are unique, and with liquid metal 3D printing, we can better meet those specific requirements. Whether it's in the aerospace, medical, or manufacturing industries, we are ready to collaborate with our clients to bring their innovative ideas to life. We also actively invest in research and development to improve our liquid metal 3D printing capabilities, ensuring that we stay at the forefront of this emerging technology.

FAQ

What types of materials can be used in liquid metal 3D printing?

Materials used in liquid metal 3D printing are mainly low - melting - point alloys. Gallium - based alloys are quite common. For example, the eutectic alloy of gallium, indium, and tin (EGaInSn) has a low melting point and excellent fluidity, making it ideal for 3D printing. Some other alloys like those based on bismuth, which also have relatively low melting points, can also be used in certain liquid metal 3D printing processes. These materials can be precisely deposited and solidified to form 3D structures.

How accurate is liquid metal 3D printing?

The accuracy of liquid metal 3D printing depends on various factors such as the printing technology used, the properties of the liquid metal, and the printer's settings. In general, current liquid metal 3D printing can achieve a dimensional accuracy in the range of tens to hundreds of micrometers. For instance, some advanced extrusion - based liquid metal 3D printers can print features with an accuracy of around 50 - 100 micrometers, which is sufficient for many applications in electronics, micro - mechanical components, and some medical device manufacturing.

What are the future development trends of liquid metal 3D printing?

In the future, liquid metal 3D printing is likely to see improvements in material diversity, with the development of new alloys and composite materials. There will also be a focus on enhancing printing speed and accuracy, perhaps through the integration of advanced control systems and more precise deposition mechanisms. Moreover, the application scope will expand further, especially in emerging fields like quantum computing and advanced aerospace propulsion systems, where the unique properties of liquid - metal - printed components can offer significant advantages.