1. Introduction: The Transformative Power of Rapid Additive Manufacturing

Rapid additive manufacturing (RAM), also known as 3D printing, is reshaping global production by enabling the creation of complex, customized parts with unprecedented speed and efficiency. Unlike traditional subtractive methods that remove material, RAM builds objects layer by layer from digital models, reducing waste and accelerating innovation. This article explores how RAM is revolutionizing industries from healthcare to aerospace, backed by technical advancements, real-world applications, and data-driven insights.

In the past few decades, the manufacturing industry has been transformed by rapid additive manufacturing, also known as 3D printing. This innovative technology has revolutionized the way products are designed, prototyped, and produced, offering numerous advantages over traditional manufacturing methods. From healthcare to aerospace, automotive to consumer goods, RAM is making its mark across various industries, enabling the creation of complex, customized parts with greater speed, efficiency, and cost - effectiveness.

The potential of RAM is vast. It has the ability to disrupt traditional supply chains, enabling on - demand production and reducing the need for large - scale inventories. It allows for greater design freedom, as complex geometries that were previously difficult or impossible to manufacture can now be produced with relative ease. Moreover, RAM can reduce the lead time from design to production, enabling companies to bring products to market faster and respond more quickly to changing customer demands.

In the following sections, Yigu Technology will delve deeper into the mechanics of rapid additive manufacturing, explore its diverse applications across different industries, and discuss the challenges and future prospects that lie ahead. By the end of this article, you will have a comprehensive understanding of how RAM is revolutionizing production and why it is set to play a crucial role in the future of manufacturing.

2. The Technical Core of Rapid Additive Manufacturing

2.1 Key Processes and Materials

Rapid additive manufacturing is not a one - size - fits - all technology; instead, it encompasses a range of processes, each with its own set of materials and applications. Understanding these processes and materials is crucial for harnessing the full potential of RAM.

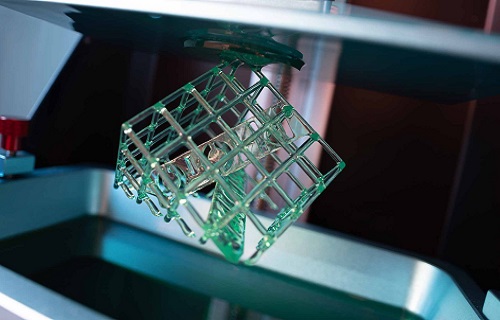

- Stereolithography (SLA): This process uses a UV laser to cure liquid resin layer by layer. The laser traces the cross - section of the object onto the surface of the resin, which solidifies upon exposure. SLA is known for its high precision and smooth surface finish, making it ideal for applications such as dental crowns, where accuracy and aesthetics are paramount, and intricate prototypes that require fine details. The primary material used in SLA is photopolymers, which are polymers that harden when exposed to light.

- Selective Laser Sintering (SLS): In SLS, a laser fuses powdered materials, such as nylon or metal, together. The laser selectively heats the powder particles, causing them to bond and form a solid layer. This process is repeated layer by layer until the object is complete. SLS can work with a wide range of materials, including polymers and metals, and is often used for creating functional tools and aerospace components. For Yigu Technology example, in the aerospace industry, SLS - printed metal parts can be used to reduce weight while maintaining structural integrity, thanks to the ability to create complex internal geometries.

- Fused Deposition Modeling (FDM): FDM extrudes melted thermoplastic filament through a nozzle. The nozzle moves in a predefined pattern, depositing the melted material layer by layer to build the object. Common materials used in FDM include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and various composites. FDM is popular for consumer goods, such as customized phone cases, and educational models due to its relatively low cost and ease of use. It is also accessible for hobbyists, as many desktop 3D printers use the FDM process.

- Binder Jetting: This process involves binding powder particles together using a liquid binder. The binder is selectively deposited onto the powder bed to form the cross - section of the object. After the green part (the unfired, bound powder) is created, it undergoes sintering, a process of heating the part to a high temperature to fuse the particles together more permanently. Binder jetting can work with ceramics and metals, and it is used for applications like high - temperature components, such as those in automotive engines, and tooling.

The following Yigu Technology table summarizes these key processes, materials, and applications:

| Technology | Process | Materials | Applications |

| Stereolithography (SLA) | UV laser cures liquid resin layer by layer. | Photopolymers | Dental crowns, intricate prototypes. |

| Selective Laser Sintering (SLS) | Laser fuses powdered materials (e.g., nylon, metal). | Polymers, metals | Functional tools, aerospace components. |

| Fused Deposition Modeling (FDM) | Extrudes melted thermoplastic filament. | PLA, ABS, composites | Consumer goods, educational models. |

| Binder Jetting | Binder binds powder particles to form green parts, followed by sintering. | Ceramics, metals | High - temperature components, tooling. |

2.2 Speed and Precision Breakthroughs

One of the most significant advantages of rapid additive manufacturing is its ability to achieve remarkable speed and precision, far surpassing traditional manufacturing methods in many cases.

- Production Cycle Reduction: RAM has revolutionized the prototyping phase. In traditional manufacturing, creating a prototype could take weeks or even months, involving multiple steps such as designing molds, machining parts, and assembling components. With RAM, this time can be cut down to hours. For instance, General Electric (GE) Aviation used SLS to reduce the development time of a fuel nozzle from 18 months to just 9 months. This drastic reduction in development time not only allows companies to bring products to market faster but also enables more iterations of design improvements in a shorter period. Faster prototyping means that companies can test and refine their products more quickly, leading to better - quality end - products.

- Tolerance Accuracy: Advanced rapid additive manufacturing systems can achieve an impressive tolerance accuracy of ±0.05mm. This level of precision is critical in industries such as medical implants and aerospace. In the medical field, implants need to fit precisely within the human body to ensure proper function and patient comfort. A small deviation in the size or shape of an implant could lead to complications. In aerospace, parts must be manufactured with extreme precision to ensure the safety and efficiency of aircraft. For Yigu Technology example, engine components need to have tight tolerances to operate effectively at high speeds and temperatures. The high precision of RAM allows for the production of parts that meet these stringent requirements, reducing the need for post - processing and ensuring better overall performance.

4. Industry Applications: Where RAM Is Making Waves

4.1 Healthcare Innovation

- 3D-Printed Organs: In 2019, Israeli researchers made headlines by creating a vascularized heart model using patient - derived cells. This was a significant leap forward in transplant research. By using the patient's own cells, the risk of organ rejection, which is a major concern in traditional organ transplantation, can be potentially mitigated. The process involved extracting cells from the patient, reprogramming them into induced pluripotent stem cells (iPSCs), and then differentiating them into the various cell types needed to build the heart. These cells were then used as “bio - ink” in a 3D printer to create a heart structure complete with blood vessels. Although this 3D - printed heart is not yet ready for transplantation into humans, it has opened up new possibilities for studying heart development, disease mechanisms, and personalized medicine. For example, pharmaceutical companies can use these 3D - printed heart models to test new drugs, reducing the need for animal testing and providing more accurate results.

- Surgical Guides: Rapid additive manufacturing has also transformed the field of surgical planning. In orthopedic surgery, for instance, RAM - produced pre - operative anatomical models are being used to create surgical guides. These guides are designed to fit precisely onto the patient's anatomy, allowing surgeons to perform procedures with greater accuracy. A study found that the use of these surgical guides reduced orthopedic surgery time by 25%. By having a detailed 3D model of the patient's bone structure, surgeons can better plan incisions, placement of implants, and bone resections. This not only shortens the surgery time but also improves the overall outcome of the procedure, leading to faster patient recovery and reduced complications.

4.2 Aerospace and Defense

- Lightweight Components: In the aerospace industry, weight reduction is crucial for improving fuel efficiency and increasing payload capacity. Airbus has been at the forefront of using rapid additive manufacturing in this regard. The company 3D - prints titanium brackets for the A350 XWB. By using 3D - printed titanium brackets, Airbus can save up to 600kg per aircraft. These 3D - printed components are not only lighter but also have complex geometries that are optimized for strength and performance. Traditional manufacturing methods would struggle to produce such complex parts with the same level of precision and efficiency. The use of 3D - printed components also reduces the number of parts needed in an aircraft, simplifying the assembly process and reducing the overall cost of production.

- Military Logistics: The U.S. Navy's deployment of portable metal printers on ships is a game - changer for military logistics. In the past, when a ship needed a replacement part, it often had to wait for the part to be shipped from a depot, which could take weeks or even months. With portable metal printers on board, the ship's crew can fabricate replacement parts on - demand. This significantly reduces the downtime of the ship and improves its operational readiness. For example, if a crucial valve or bracket breaks during a mission, the crew can simply download the 3D model of the part, print it using the metal printer, and install it, getting the ship back in operation quickly.

4.3 Automotive and Mobility

- Electric Vehicles (EVs): Tesla, a leader in the electric vehicle industry, has been leveraging rapid additive manufacturing to accelerate its product development. The company uses RAM to prototype battery enclosures, cutting the development cycle by 50%. Battery enclosures are a critical component of EVs, as they need to protect the battery cells from external impacts and environmental factors. By using 3D printing for prototyping, Tesla can quickly test different designs, make modifications, and iterate on the design until it meets the required specifications. This rapid prototyping process allows Tesla to bring new EV models to market faster, giving them a competitive edge in the rapidly evolving EV market.

- Sustainable Design: The use of carbon - fiber - reinforced PLA parts in the automotive industry is another example of how RAM is enabling sustainable design. These parts are lighter than traditional metal parts, which improves the fuel efficiency of vehicles. A study showed that for every 10% reduction in vehicle weight, fuel efficiency can be improved by 6 - 8%. By using 3D - printed carbon - fiber - reinforced PLA parts, automotive manufacturers can reduce the weight of their vehicles without sacrificing strength. These parts can be customized for different vehicle models, allowing for a more tailored and efficient design. Additionally, the use of PLA, a biodegradable material, reduces the environmental impact of vehicle production and disposal.

6. Conclusion: The Future of Production Is Additive

Yigu Technology Rapid additive manufacturing is no longer a niche technology—it is a cornerstone of modern production, driving innovation, sustainability, and agility across industries. As RAM continues to evolve, its integration with AI, advanced materials, and circular economy practices will redefine how we design, produce, and distribute goods.

The data speaks volumes about the growing impact of RAM. The global 3D printing market is projected to reach $62.15 billion by 2027, with a compound annual growth rate (CAGR) of 21.4% from 2020 to 2027. This growth is not just a sign of market expansion; it is a testament to the increasing adoption of RAM in mainstream production.

Industries are already reaping the benefits. In healthcare, RAM - printed implants and prosthetics are improving patient outcomes. In aerospace, lightweight 3D - printed components are enhancing fuel efficiency and performance. In automotive, the technology is accelerating the development of electric vehicles and enabling sustainable design.

FAQ

Is RAM Cost - Effective?

RAM reduces upfront tooling costs but may have higher unit costs for large volumes. However, its ability to iterate designs and reduce waste often leads to long - term savings. For example, in the production of a complex aerospace component, traditional manufacturing might require expensive molds that cost \(50,000. With RAM, these tooling costs are eliminated. Although the per - unit cost of a 3D - printed part might be \)500 compared to \(300 for a traditionally - manufactured part in high - volume production, the ability to quickly iterate the design and reduce material waste can lead to significant savings over time. If the design needs to be changed three times during development, with traditional manufacturing, each change might cost an additional \)10,000 for mold modifications. With RAM, these changes can be made at a much lower cost, perhaps only $1,000 for additional materials and a bit more in printing time.

Which Industries Benefit Most from RAM?

Healthcare, aerospace, and automotive industries gain significant advantages from RAM’s customization and lightweighting capabilities. In healthcare, the ability to create patient - specific implants is revolutionary. For instance, a 3D - printed hip implant can be customized to fit the unique anatomy of a patient, improving the success rate of the surgery and reducing recovery time. The global market for 3D - printed medical devices is expected to reach \(6.3 billion by 2025, with a CAGR of 20.6% from 2020 - 2025. In the aerospace industry, as mentioned earlier, the weight reduction achieved through 3D - printed components can lead to substantial fuel savings. Airbus estimates that by using 3D - printed parts, they can save up to \)1.5 million per aircraft over its lifespan in fuel costs. In the automotive industry, RAM enables faster prototyping and the production of lightweight, sustainable parts, as demonstrated by Tesla's use of RAM for battery enclosure prototyping.

Is RAM Environmentally Friendly?

Yes. RAM minimizes material waste and energy use, aligning with sustainability goals. Traditional manufacturing methods often produce a large amount of waste. For example, in subtractive machining of a metal part, up to 90% of the original material can be discarded. In contrast, RAM builds parts layer by layer, using only the necessary amount of material, with waste typically less than 10%. Additionally, recycled materials and closed - loop systems further reduce its environmental impact. Some companies are now using recycled plastics in their 3D - printing processes. For instance, a startup has developed a method to recycle plastic waste into filament for FDM 3D printers. This not only reduces the amount of plastic waste in landfills but also decreases the demand for virgin plastic materials, contributing to a more sustainable manufacturing ecosystem.