Introduction

Unveiling the Concept of 3D Printed Locomotives

In the ever - evolving landscape of technology, the concept of 3D printed locomotives has emerged as a revolutionary idea. But what exactly are 3D printed locomotives? At its core, a 3D printed locomotive is a railway vehicle whose components are fabricated using 3D printing technology, also known as additive manufacturing.

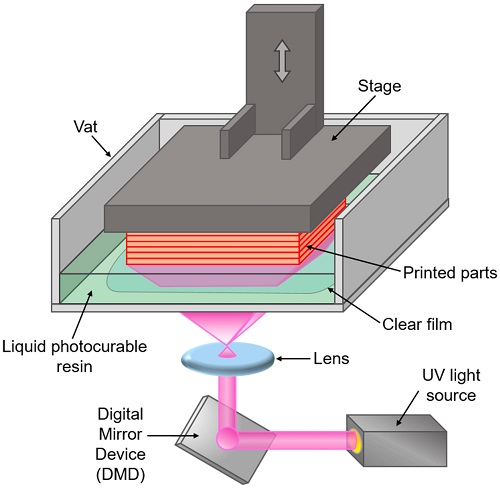

Unlike traditional manufacturing methods that often involve subtracting materials through processes like cutting and milling, 3D printing builds objects layer by layer from a digital model. For locomotives, this means that instead of assembling numerous pre - made parts manufactured through different traditional techniques, many components can be printed in one piece or with fewer sub - assemblies.

The digital model serves as the blueprint. It is sliced into thin cross - sectional layers by specialized software. The 3D printer then reads these layers and deposits materials such as plastics, metals (like aluminum or titanium alloys), or composite materials in precise patterns to gradually build up the three - dimensional structure of the locomotive component. For example, a complex part of the locomotive's chassis or a unique - shaped component of its engine could be printed directly, reducing the need for multiple molds and complex machining operations.

This innovative approach to locomotive production has the potential to disrupt the traditional railway manufacturing industry. It challenges long - standing norms and opens up a world of possibilities in terms of design freedom, cost - effectiveness, and production speed. In the following sections, we will explore the various aspects of 3D printed locomotives, from their design and manufacturing processes to their advantages, challenges, and future prospects.

Comparison with Traditional Locomotive Manufacturing

Cost Comparison

When it comes to the cost of locomotive manufacturing, 3D printing and traditional manufacturing methods show significant differences. In traditional locomotive manufacturing, the initial investment in tooling and molds is extremely high. For example, creating a mold for a complex locomotive part can cost hundreds of thousands of dollars. Additionally, the cost of machining, assembly, and quality control in traditional manufacturing accumulates throughout the production process.

| Cost Aspect | Traditional Manufacturing | 3D Printing |

| Initial Tooling and Molds | High - Can cost hundreds of thousands to millions of dollars for complex molds. | Low - Digital models replace the need for most physical molds, reducing upfront costs significantly. |

| Material Waste | High - Subtractive manufacturing processes often result in a large amount of material being cut away and wasted, increasing material costs. | Low - Additive manufacturing in 3D printing builds parts layer by layer, minimizing material waste, which can lead to cost savings, especially for expensive materials. |

| Assembly Costs | High - Many pre - made parts need to be assembled, requiring a large workforce and time, thus increasing labor costs. | Lower - Some components can be printed as one piece, reducing the number of parts to be assembled and potentially lowering labor costs. |

Production Time Comparison

The production time of locomotives also varies greatly between traditional and 3D printing methods. Traditional manufacturing involves multiple sequential steps, from designing and creating molds to machining parts and assembling them. This process can take months or even years for a new locomotive model.

3D printing, on the other hand, can significantly reduce production time. Once the digital model is ready, the 3D printer can start building the components immediately. In some cases, a single 3D - printed part can be produced within hours to a few days, depending on its size and complexity.

Here is a simple bar chart to illustrate the difference:

| Manufacturing Method | Average Production Time for a Locomotive (Excluding Design Phase) |

| Traditional Manufacturing | 6 - 18 months |

| 3D Printing | 1 - 3 months (for a significant portion of components, with potential for faster overall production when optimized) |

Design Flexibility Comparison

Traditional Manufacturing:

- Design changes in traditional manufacturing are complex and costly. Once the molds are created, modifying the design often requires creating new molds, which can be time - consuming and expensive.

- The design is somewhat restricted by the limitations of traditional manufacturing processes. For example, complex internal geometries are difficult and costly to achieve.

3D Printing:

- Offers high design flexibility. Designers can create highly complex and customized shapes with ease. They can modify the digital model at any time, and the 3D printer will produce the updated version without the need for significant re - tooling.

- Internal structures can be designed to be lightweight and optimized for performance, such as lattice structures within locomotive components, which are nearly impossible to produce with traditional methods.

In summary, 3D printing offers distinct advantages over traditional manufacturing in terms of cost - effectiveness, production time, and design flexibility when it comes to locomotive manufacturing. However, it also faces challenges, which we will explore in the next section.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology holds a positive view on the application of 3D printing in locomotive manufacturing.

In terms of materials, Yigu Technology believes that the continuous expansion of 3D printing materials provides more possibilities for locomotive production. For example, advanced composite materials can be used to print locomotive components, which not only have high strength - to - weight ratios but also can enhance the durability and performance of locomotives.

Regarding custom - made production, 3D printing aligns perfectly with Yigu Technology's business concept. The ability to quickly produce customized non - standard parts for locomotives means that locomotive manufacturers can better meet the diverse needs of different railway projects. Whether it's a special - shaped component for a narrow - gauge railway locomotive or a customized part for a high - speed train, 3D printing can achieve efficient production, reducing lead times and costs for custom projects.

FAQs

What are the most common materials used for 3D printed locomotives?

The most common materials for 3D printed locomotives include metals like aluminum alloys and titanium alloys. Aluminum alloys are popular due to their high strength - to - weight ratio, corrosion resistance, and relatively low cost. They can be used to print components such as the locomotive's body frame, which needs to be lightweight yet strong enough to withstand the rigors of railway operations. Titanium alloys, on the other hand, offer excellent strength, heat resistance, and corrosion resistance, making them suitable for parts that endure high - stress and high - temperature conditions, like engine components.

Plastics, especially high - performance engineering plastics such as polyetheretherketone (PEEK), are also used. PEEK has high mechanical strength, chemical resistance, and can withstand high temperatures. It can be used for printing smaller components like gears and bearings within the locomotive, where its self - lubricating properties can reduce friction and wear.

How does the performance of 3D printed locomotives compare to traditional ones?

In terms of performance, 3D printed locomotives can have some advantages. Due to their ability to create complex internal structures, 3D printed components can be optimized for weight reduction while maintaining strength. This can lead to improved energy efficiency as the locomotive requires less energy to move.

However, traditional locomotives have the advantage of a long - established production process with well - understood quality control. The materials and manufacturing techniques have been refined over decades, ensuring consistent performance. 3D printed locomotives are still in the development stage in many aspects, and issues such as the long - term durability and reliability of 3D printed components under continuous heavy - duty use need further research and improvement.

Are 3D printed locomotives suitable for high - speed rail operations?

3D printed locomotives face both opportunities and challenges for high - speed rail operations. On the one hand, the design flexibility of 3D printing allows for the creation of components with aerodynamic shapes that can reduce air resistance at high speeds. This can potentially improve the overall energy efficiency and speed capabilities of high - speed trains.

On the other hand, high - speed rail operations demand extremely high levels of safety, reliability, and precision. The long - term performance and fatigue resistance of 3D printed materials and components under the high - stress and high - frequency vibrations of high - speed travel are still areas of concern. Extensive testing and development are needed to ensure that 3D printed locomotives can meet the stringent requirements of high - speed rail operations.