1. Introduction

What exactly is a 3D printed rocket model? In simple terms, it is a rocket model crafted through the innovative 3D printing technology. Instead of traditional manufacturing methods that often involve complex molds and multiple production steps, 3D printing builds the rocket model layer by layer based on a digital design. This revolutionary approach has opened up a whole new world of possibilities for rocket model enthusiasts, students, and even aerospace engineers conducting research.

The development of 3D printed rocket models has been a remarkable journey. In the past, creating a detailed rocket model was a time - consuming and costly process. However, with the advent of 3D printing technology, the barriers to entry have been significantly lowered. Now, individuals with basic 3D printing knowledge can bring their rocket model designs to life in their own workshops or at home. This article will explore various aspects of 3D printed rocket models, from their design flexibility and cost - effectiveness to the materials used and their performance in different scenarios. Whether you are a hobbyist looking to build your first 3D printed rocket model or a professional interested in the latest advancements in the field, read on to discover more about these fascinating creations.

2. The Basics of 3D Printed Rocket Models

2.1 What is a 3D Printed Rocket Model?

A 3D printed rocket model is a scale - representation of a real rocket, fabricated using 3D printing technology. This technology, also known as additive manufacturing, works by depositing material layer by layer to create a three - dimensional object based on a digital design file, typically in a.STL (Stereolithography) format.

There are several common 3D printing technologies used in creating rocket models:

- Fused Deposition Modeling (FDM): This is one of the most accessible 3D printing methods, often used by hobbyists. FDM printers work by melting a filament of thermoplastic material, such as ABS (Acrylonitrile Butadiene Styrene) or PLA (Polylactic Acid), and extruding it through a nozzle. The melted material is deposited layer by layer onto a build platform, solidifying as it cools. For rocket models, FDM is great for creating large - scale, cost - effective prototypes due to its relatively low - cost materials and ease of use. However, the surface finish may be a bit rough, with visible layer lines.

- Selective Laser Sintering (SLS): SLS uses a high - power laser to sinter powdered materials, such as nylon or metal powders, together. In the context of rocket model making, SLS can produce parts with excellent mechanical properties and a relatively smooth surface finish. Since it doesn't require support structures (as the unsintered powder supports the part during printing), it's suitable for creating complex internal geometries that are often found in rocket components. But SLS printers are more expensive, and the process can be time - consuming.

- Stereolithography (SLA): SLA printers use a laser to cure liquid photopolymer resin layer by layer. This results in extremely high - resolution prints with smooth surfaces, making it ideal for creating highly detailed rocket models, especially those with fine features. SLA - printed models are often used for display purposes or when high precision is required, such as in aerospace research models. However, the resin materials can be more expensive, and the cured parts may be brittle compared to those made with other materials.

2.2 Key Components of 3D Printed Rocket Models

- Engine: The engine is the heart of the rocket model. With 3D printing, it's possible to create complex engine designs with internal channels for fuel flow and combustion chambers. For example, using SLS or metal 3D printing techniques, one can fabricate an engine with optimized cooling channels. These channels are difficult to create using traditional manufacturing methods but can be printed directly, improving the engine's performance and efficiency.

- Fuel Tank: Fuel tanks for 3D printed rocket models can be printed in various shapes and sizes to fit the design requirements. FDM - printed fuel tanks made of materials like PLA or ABS can be used for small - scale, non - high - pressure applications. For more advanced models, SLS - printed nylon fuel tanks can offer better strength - to - weight ratios. The ability to print fuel tanks with custom geometries allows for better integration with the overall rocket structure, maximizing the available space for fuel storage.

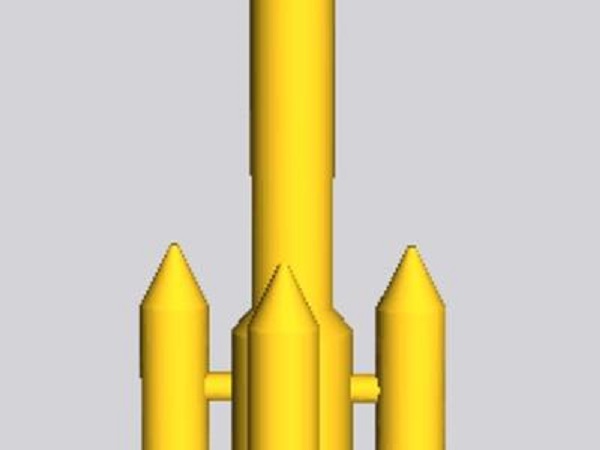

- Fins: Fins are crucial for the stability of the rocket during flight. 3D printing enables the creation of fins with unique shapes and aerodynamic profiles. Whether it's a simple triangular fin or a more complex, swept - back design for better high - speed performance, FDM or SLA can be used to print fins with high precision. Additionally, 3D printing allows for the incorporation of lightweight internal structures within the fins, reducing weight without sacrificing strength.

- Payload Bay: If the rocket model is designed to carry a payload (such as a small sensor or a miniature satellite model), the payload bay can be 3D printed to the exact dimensions required. This ensures a perfect fit for the payload and easy access for installation and removal. SLA - printed payload bays often provide a smooth interior finish, protecting the payload from scratches and damage during launch and flight.

3. Comparison with Traditional Rocket Models

When considering 3D printed rocket models, it's essential to compare them with traditional rocket models to understand their advantages and differences. The following aspects can be compared in tabular form:

| Comparison Items | 3D Printed Rocket Models | Traditional Rocket Models |

| Material Utilization | High. 3D printing only uses the amount of material required for the design, with little waste. For example, when printing a complex - shaped engine part, the material is precisely deposited where needed, and the material utilization rate can reach over 90% in some cases. | Low. Traditional manufacturing methods often involve processes like cutting, milling, and casting, which generate a significant amount of waste material. For instance, in casting a metal rocket component, the excess material removed during post - processing can account for 30 - 50% of the initial raw material. |

| Production Cycle | Short. A simple 3D printed rocket model can be completed within a few days, depending on the complexity of the design and the size of the model. For hobbyists using desktop 3D printers, a small - scale rocket model might be printed in 1 - 2 days. Even for more complex aerospace - grade models, the production time can be weeks rather than months. | Long. Traditional rocket model production requires multiple steps, including mold making, component manufacturing, and assembly. A medium - sized traditional rocket model may take several weeks to a month to complete, especially when complex molds need to be crafted by hand. |

| Manufacturing Cost | Lower for small - scale production and complex designs. The cost mainly lies in the 3D printer, materials, and electricity. For example, a desktop FDM 3D printer can cost around \(200 - \)2000, and the cost of PLA filament (a common 3D printing material) is about \(20 - \)50 per kilogram. For small - batch production of rocket models, the overall cost can be relatively low. However, for large - scale production, the cost per unit may be higher than traditional methods until economies of scale are achieved. | Higher for small - scale production, especially when considering the cost of mold making and labor - intensive processes. For a traditional rocket model manufacturer, setting up molds for a new design can cost thousands of dollars, and the labor cost for skilled workers to operate machinery and assemble components is also significant. But for large - scale production, the cost per unit can be reduced due to economies of scale. |

| Design Complexity | High. 3D printing can easily create complex geometries, internal structures, and lattice designs that are difficult or impossible to achieve with traditional methods. For example, a rocket model with internal cooling channels in the engine or lightweight lattice - structured fins can be printed directly without additional manufacturing steps. | Limited. Traditional manufacturing methods have limitations in creating complex designs. Complex shapes may require multiple parts to be fabricated separately and then assembled, increasing the complexity and cost of production. For instance, creating a rocket engine with an intricate internal combustion chamber shape using traditional machining would be extremely challenging and costly. |

4. Real - World Applications and Examples

4.1 NASA's 3D Printed Rocket Engine

NASA has been at the forefront of using 3D printing technology in rocket engine manufacturing. One notable example is the "RS - 25" engine. The fuel nozzles of this engine are 3D printed, which brings several significant advantages. These 3D printed nozzles can be designed with complex internal geometries that are optimized for fuel injection. For instance, they can have precisely engineered channels to ensure a more uniform and efficient fuel - air mixture, resulting in better combustion efficiency. According to NASA's research, the use of 3D printed components in the RS - 25 engine has reduced the overall production cost by nearly 35%. This cost - reduction is mainly due to the elimination of complex mold - making processes and the ability to produce parts with less material waste. Moreover, the 3D printed fuel nozzles can withstand extremely high temperatures and pressures during rocket launches, maintaining high - performance and reliability, which is crucial for space missions.

4.2 SpaceX's Rocket Components

SpaceX has also made extensive use of 3D printing in its rocket manufacturing, especially in the "Falcon 9" rocket. Many components of the Falcon 9, such as the engine's fuel nozzles and some structural parts, are 3D printed. By using 3D printing, SpaceX has been able to significantly improve the production speed. For example, the production cycle of some 3D printed parts has been reduced from months to just a few days. This allows SpaceX to quickly respond to the increasing demand for rocket launches. In terms of cost, 3D printing has also played a role in cost - control. Traditional manufacturing methods for these components often involve multiple steps and high - cost tooling. With 3D printing, the number of production steps is reduced, and the need for expensive molds is eliminated, leading to a substantial cost reduction. In addition, the 3D printed parts can be designed to be more lightweight while maintaining their strength, which is beneficial for improving the rocket's performance and payload capacity.

4.3 Relativity Space's Terran 1

Relativity Space's Terran 1 rocket is a remarkable example of the potential of 3D printing in the aerospace industry. An astonishing 85% of the Terran 1 rocket is made up of 3D printed components. This high proportion of 3D printed parts represents a significant shift from traditional rocket manufacturing methods. By using 3D printing, Relativity Space can simplify the supply chain. Instead of relying on numerous suppliers for different parts, they can produce a large number of components in - house with their 3D printers. The 3D printed parts also allow for more innovative designs. For example, the engine components can be printed with complex cooling channels that are difficult to achieve through traditional manufacturing. This improves the engine's thermal management and overall performance. Looking ahead, Terran 1 paves the way for future 3D - printed rockets. With further development, we can expect to see even more advanced rockets with an even higher percentage of 3D printed parts, leading to more efficient, cost - effective space launches.

5. Yigu Technology's Viewpoint

As a non - standard plastic metal products custom Supplier, Yigu Technology recognizes the great potential of 3D printing in rocket model manufacturing. In terms of materials, we understand the importance of selecting the right ones for different components. For example, for rocket model bodies, we can offer high - strength and lightweight plastic materials that are suitable for 3D printing, which can enhance the overall performance of the model while reducing weight.

When it comes to custom - made services, Yigu Technology has the ability to meet various special requirements. Whether it's a unique design of a rocket model's engine or a customized payload bay, we can use our advanced 3D printing technology and rich experience to turn ideas into reality. Our team of experts can work closely with clients, from the initial design concept to the final production, ensuring that every detail meets the client's expectations. We believe that by combining our material expertise and custom - made capabilities, we can contribute to the development of more innovative and high - quality 3D printed rocket models.