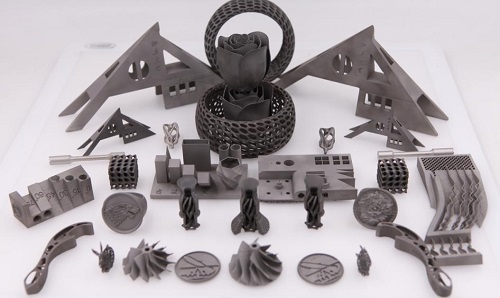

Introduction to Multi Jet Fusion 3D Printing

Multi Jet Fusion (MJF) is an advanced 3D printing technology developed by Hewlett-Packard (HP) that combines the speed and precision of inkjet printing with the capabilities of additive manufacturing. MJF is known for producing high-quality parts with complex geometries, smooth surfaces, and minimal post-processing. This technology has been widely adopted across various industries, including aerospace, automotive, and healthcare, due to its speed, flexibility, and ability to produce both functional prototypes and end-use parts.

Definition and Basic Principles

At its core, MJF is an additive manufacturing process that creates 3D objects layer by layer. It uses specialized powder materials, which are selectively fused using fusing agents and detailing agents applied by inkjet print heads. The process involves spreading a layer of powdered material across a build platform, followed by applying fusing and detailing agents to the material. Then, the platform is heated to fuse the material and create solid parts. MJF's use of multiple jets to apply agents, combined with its precise heat control, ensures high-quality prints with fine details, excellent surface finishes, and strong mechanical properties.

Comparison with Other 3D Printing Technologies

While MJF shares some similarities with other additive manufacturing techniques, its unique features make it stand out. Here's how it compares to other popular 3D printing methods:

Fused Deposition Modeling (FDM)

- FDM uses melted thermoplastic filament extruded through a nozzle to build parts layer by layer.

- Advantages: Simple, cost-effective, and versatile.

- Limitations: FDM tends to produce parts with visible layer lines and lower resolution compared to MJF. It also struggles with intricate geometries.

- MJF offers a smoother surface finish, higher resolution, and can produce more complex geometries without the visible layer lines seen in FDM prints.

Stereolithography (SLA)

- SLA uses a laser to cure liquid resin into solid parts.

- Advantages: High resolution and excellent surface finish.

- Limitations: SLA is slower and more expensive than MJF and typically requires post-processing steps like cleaning and curing.

- MJF is faster, produces parts with similar or better resolution, and often requires minimal post-processing compared to SLA.

Selective Laser Sintering (SLS)

- SLS uses a laser to sinter powdered material, binding it into solid parts.

- Advantages: Capable of producing strong and complex parts with good material options.

- Limitations: SLS is often slower and can be more expensive due to the high cost of laser-based equipment and specialized materials.

- MJF is faster, more cost-effective for producing complex parts, and uses a broader range of materials compared to SLS.

Multi Jet Fusion (MJF)

- MJF combines features from inkjet printing, powder-based 3D printing, and thermal fusing. The technology allows for high-speed production, excellent precision, and complex geometries with fine surface finishes. It stands out because of its speed, versatility, and reduced need for post-processing.

How Multi Jet Fusion Works

The Printing Process Explained

MJF works through a series of steps, each contributing to the creation of high-quality parts:

- Powder Bed Preparation:

A thin layer of nylon powder (or other materials) is spread evenly across the build platform using a roller mechanism. This serves as the base for the next layers of printing. - Inkjet Head Operation:

Inkjet print heads pass over the powder bed and selectively deposit two types of agents:- Fusing agents: These agents help the powder fuse together when heated.

- Detailing agents: These agents refine the surface finish of the printed part.

- Heating and Fusing:

The build platform is heated to around 170°C (338°F), causing the areas treated with the fusing agent to melt and bond together. The detailing agent helps ensure finer surface resolution. The powder particles without the fusing agent remain unfused and help provide structural integrity to the part. - Layer Repetition:

After each layer is fused, the platform lowers slightly, and another layer of powder is spread across the surface. The process repeats for each new layer, building the part layer by layer. - Cooling and Removal:

Once the printing process is complete, the part cools inside the machine. The remaining unused powder is removed, revealing the final printed part. Because of MJF's precise control over the material, minimal post-processing is required, often just cleaning off the excess powder.

Material Deposition and Layering

MJF's success lies in its precise deposition of fusing and detailing agents. Each layer is carefully built to ensure it adheres to the previous layer, creating strong, durable, and high-resolution parts. This layer-by-layer approach, combined with the fine nylon powders, allows MJF to achieve fine details and smooth finishes not found in some other 3D printing techniques.

Applications of Multi Jet Fusion

MJF’s unique combination of speed, quality, and material properties makes it ideal for a wide range of industries and applications. Here are some key sectors where MJF is making an impact:

Industrial Uses and Benefits

Aerospace Industry

MJF is used to create lightweight, strong, and durable components for the aerospace industry. The ability to manufacture complex geometries quickly helps reduce part weight while maintaining strength, which is essential for both aircraft structures and engine components. MJF also accelerates the prototyping and development of parts, significantly reducing time-to-market.

Automotive Industry

The automotive sector benefits from MJF’s ability to produce functional prototypes and end-use parts quickly. MJF has been used to create components such as instrument panels, brackets, and functional prototypes. The technology helps automotive manufacturers meet demands for customization, lightweighting, and improved fuel efficiency.

Healthcare Sector

In healthcare, MJF enables the creation of custom prosthetics, orthotics, and dental implants tailored to individual patients' needs. It’s also used for anatomical models, which assist surgeons in pre-surgical planning, as well as in medical training and education.

Case Studies and Success Stories

Case Study 1: Aerospace Innovation

A leading aerospace manufacturer used MJF to produce engine components with intricate internal cooling channels. This approach reduced the development time by 50% compared to traditional manufacturing. The component met all performance criteria and was quickly moved into testing.

Case Study 2: Automotive Efficiency

A well-known automotive manufacturer used MJF to redesign a suspension bracket, optimizing it for weight reduction without compromising strength. This resulted in a 20% weight reduction, which improved fuel efficiency and handling dynamics.

Case Study 3: Medical Advancements

A healthcare startup used MJF to produce customized knee braces for post-surgery recovery. By tailoring the braces based on patient-specific data (from 3D scans), the company enhanced the comfort and effectiveness of the braces, improving patient recovery time and satisfaction.

FAQs

What are the main advantages of Multi Jet Fusion (MJF) 3D printing?

MJF offers several benefits, including:

- High speed and precision, enabling faster production times.

- The ability to produce complex geometries without sacrificing surface finish or strength.

- Minimal post-processing, as parts are created with smooth finishes and fine details.

- Versatility for both functional prototypes and end-use parts, with applications across industries.

Is Multi Jet Fusion (MJF) suitable for large-scale production?

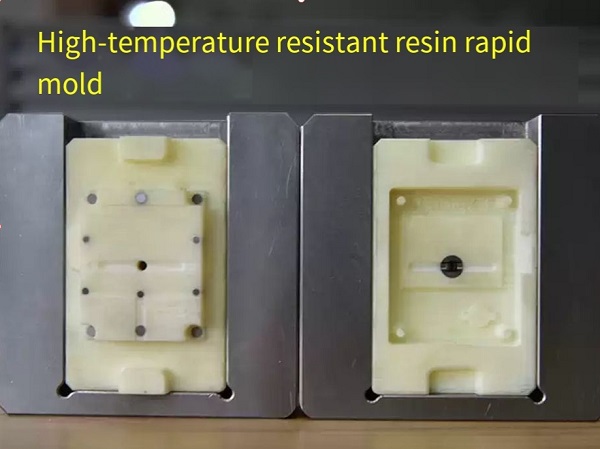

While MJF is often used for rapid prototyping and small-batch production, it can be scaled for larger production runs when combined with other manufacturing methods. It is particularly effective for producing parts with intricate designs that other technologies may struggle with.

What materials can be used with Multi Jet Fusion (MJF)?

Currently, nylon-based materials, such as Nylon 12, are commonly used in MJF due to their compatibility with the fusing and detailing agents. These materials offer excellent mechanical properties, durability, and flexibility, making them suitable for a wide range of applications. Research is ongoing to expand the material options available for MJF printing.

Conclusion

Multi Jet Fusion (MJF) is a highly efficient and versatile 3D printing technology that excels in speed, precision, and producing high-quality parts with minimal post-processing. Its ability to create complex geometries and functional prototypes quickly makes it a game-changer for industries such as aerospace, automotive, and healthcare. As the technology continues to evolve, MJF is likely to see even broader adoption, revolutionizing manufacturing processes across various sectors.