Introduction to Ordering 3D Prints

Ordering 3D prints can seem daunting, but with proper preparation, it becomes straightforward. This guide walks you through every step, from selecting a 3D printing service to preparing your model, understanding printing processes, and managing post-production. By following these steps, you can ensure a smooth, efficient experience and high-quality results.

Overview of 3D Printing Services

Online 3D Printing Services

Online platforms like Shapeways, Sculpteo, and i.materialise allow you to upload models, select materials, and place orders conveniently. These services offer diverse materials and finishes, suitable for prototyping or final products.

Local 3D Printing Providers

Local services offer personalized support and in-person consultations. They are ideal for customized projects and quick turnarounds, often providing design assistance and tailored post-processing options.

Benefits of 3D Printed Products

- Customization: Unique, tailor-made designs.

- Speed: Faster production timelines.

- Cost-Effectiveness: Competitive for small batches.

- Complexity: Handles intricate geometries.

- Material Variety: Options include plastics, metals, and composites.

Choosing a 3D Printing Service

Criteria for Selecting a Provider

- Reputation: Check reviews and portfolios for experience with similar projects.

- Capabilities: Ensure they support your required technology and materials.

- Pricing: Compare quotes to avoid hidden fees.

- Turnaround Time: Confirm they can meet your deadlines.

- Customer Service: Look for responsive and clear communication.

Researching and Comparing Services

Compile a list of potential providers, ask detailed questions, and request multiple quotes. Evaluate based on cost, quality, and delivery timelines.

Preparing Your 3D Model

File Formats and Compatibility

Most services accept STL, OBJ, STEP, and IGES files. Confirm with your provider to ensure compatibility.

Tips for Model Preparation

- Wall Thickness: Maintain at least 1–2 mm.

- Orientation: Optimize for strength and surface finish.

- Support Structures: Plan for or discuss their inclusion with your provider.

- Holes and Cavities: Avoid designs that trap air or fail to print properly.

Recommended Software

- Tinkercad: For beginners.

- Fusion 360: Advanced CAD features.

- Meshmixer: Model repair and editing.

- Cura: Slicing software to prepare G-code for printing.

Understanding the Printing Process

Common 3D Printing Technologies

- FDM: Affordable, versatile, with visible layer lines.

- SLA: High detail and smooth finish.

- SLS: Complex, functional parts with durable nylon.

- DLP: Fast, high-resolution printing.

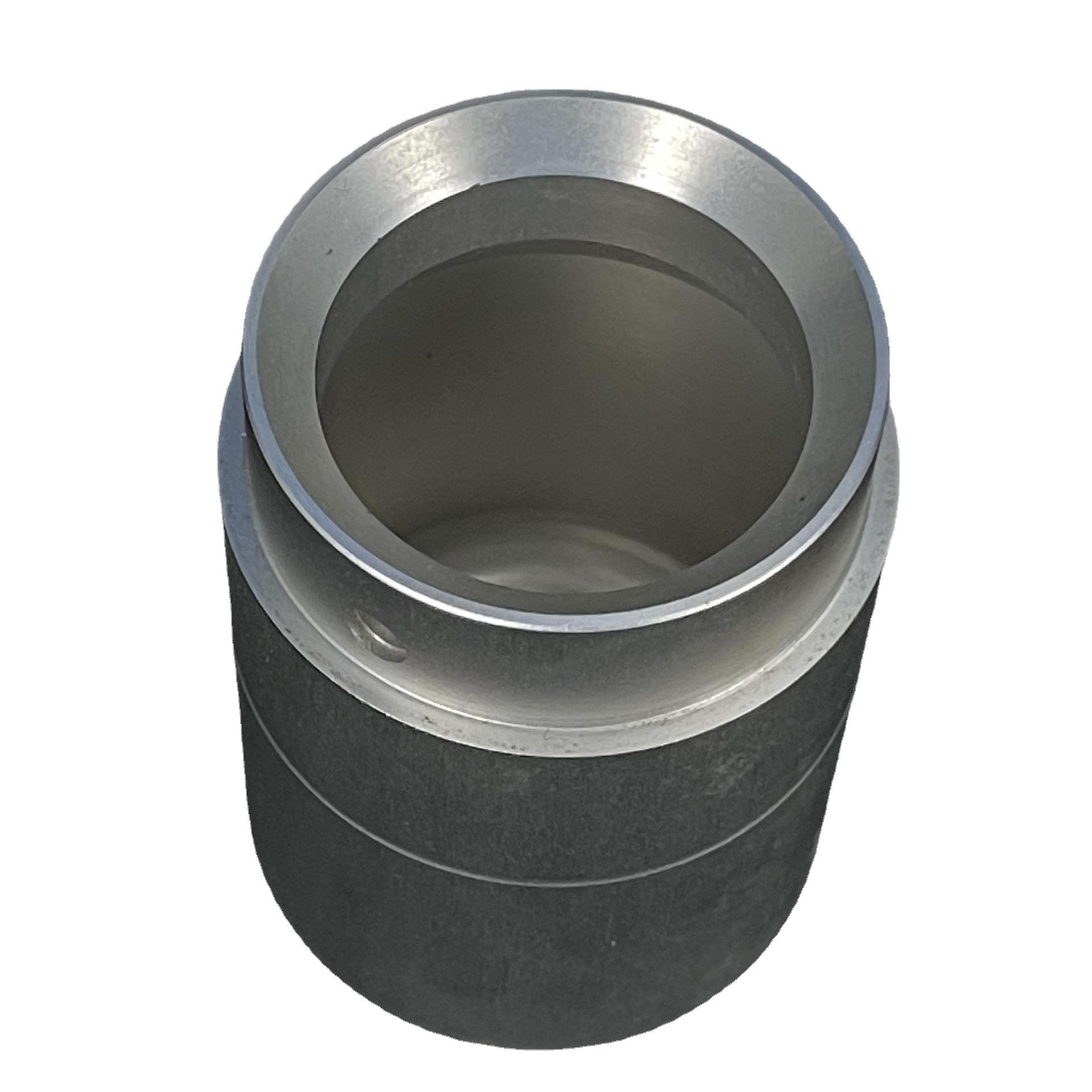

- Metal 3D Printing: High-strength industrial applications.

Material Options

- Plastics: PLA, ABS, PETG, Nylon (varying strength and flexibility).

- Resins: High detail, smooth finish, but brittle.

- Metals: Titanium, aluminum for strength and durability.

- Composites: Lightweight and strong combinations.

Print Resolution

Measured in microns, higher resolutions (20–100 μm) yield finer details but increase costs and time.

Post-Processing and Finishing

Available Post-Processing Services

- Support Removal: Manual or automated tools.

- Sanding & Polishing: Smooth surfaces with abrasive materials.

- Painting & Priming: Enhance appearance or protect surfaces.

- Assembly: Secure parts with adhesives or connectors.

- Heat Treatment: Improve mechanical properties.

- Plating & Anodizing: Add decorative or protective metal coatings.

DIY Techniques

- Sanding: Gradually move from coarse to fine grits.

- Polishing: Use compounds for a glossy finish.

- Heat Guns: Smooth layer lines in thermoplastics.

- Painting: Apply primer and paint in thin, even layers.

Quality Assurance

Thoroughly inspect the printed part for defects, rough edges, or unremoved supports. Test its functionality to confirm it meets your specifications.

Cost Estimation and Budgeting

Estimating Costs

- Material Costs: Based on weight/volume.

- Service Fees: Vary by complexity and provider.

- Shipping: Factor in size, weight, and destination.

- Post-Processing: Additional services may increase costs.

Cost-Saving Tips

- Simplify Designs: Reduce material usage and complexity.

- Opt for Affordable Materials: Use cost-effective options like PLA or ABS.

- Batch Orders: Save with bulk discounts.

- Negotiate: Request discounts for large or repeat projects.

- Local Providers: Avoid shipping fees with nearby services.

Key Takeaways

- Plan Ahead: Research and prepare thoroughly.

- Communicate Clearly: Provide detailed specifications.

- Optimize Costs: Choose materials and designs that balance cost and performance.

By following this guide, you can streamline the process of ordering 3D prints, ensuring efficient project execution and high-quality outcomes.