Introduction to Additive Manufacturing Services

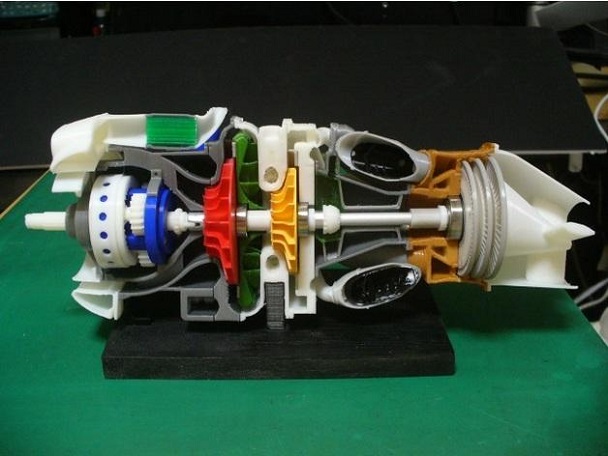

Additive manufacturing services, commonly known as 3D printing services, are revolutionizing how products are designed, developed, and produced. Unlike traditional manufacturing, where parts are made by subtracting material from a larger block (like milling or casting), additive manufacturing involves building parts layer by layer from the ground up, based on digital designs. This process allows for greater design flexibility, cost efficiency, and faster production cycles, making it ideal for industries where traditional methods are either too slow, expensive, or restrictive.

Definition and Process

At the heart of additive manufacturing is a layer-by-layer production process that involves the following steps:

- Design: A 3D digital model is created using Computer-Aided Design (CAD) software.

- Preparation: The model is sliced into thin cross-sections using slicing software, which translates the design into a series of instructions for the printer.

- Printing: The 3D printer uses the sliced data to build the part by adding material one layer at a time. This can involve a range of materials, including plastics, metals, ceramics, and even bio-materials.

- Finishing: Post-processing may be required to clean, cure, or polish the printed part to meet the desired quality standards.

This approach supports a variety of materials, making additive manufacturing highly versatile and adaptable for different applications and industries.

History and Evolution

Additive manufacturing can trace its origins to the 1980s, when Chuck Hull developed the first commercial 3D printing technology, stereolithography (SLA). Since then, the field has seen significant advancements, with the introduction of various techniques such as Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM). Over the years, as materials, printer capabilities, and software have improved, 3D printing has grown beyond rapid prototyping to support full-scale production across multiple industries, including aerospace, automotive, medical, and consumer goods.

Benefits of Additive Manufacturing

1. Time and Cost Efficiency

Additive manufacturing significantly reduces production time and costs compared to traditional manufacturing. By eliminating the need for expensive molds, tooling, and long setup times, it speeds up the entire production process. For low-volume or custom part production, 3D printing offers a far more economical alternative, especially for prototypes and end-use parts.

2. Design Flexibility

Additive manufacturing is uniquely suited for creating complex geometries and intricate designs that would be nearly impossible or prohibitively expensive to produce with traditional methods. Designers can optimize parts for performance, weight, and aesthetic appeal, without the constraints of conventional manufacturing processes. This leads to greater creativity and innovation in product development.

3. Material Optimization

With 3D printing, the exact amount of material required for a part is used, leading to minimal waste. This can be especially important in industries where materials are expensive or have limited availability, such as aerospace or medical fields. Some additive manufacturing processes also allow for multi-material printing, where different materials can be combined within a single part to achieve specific properties, such as enhanced strength or flexibility.

Applications Across Industries

1. Aerospace

In the aerospace industry, 3D printing is used to create lightweight, strong, and complex components. For example, GE Aviation has adopted additive manufacturing to produce fuel nozzles for jet engines, resulting in parts that are both lighter and more efficient. The ability to quickly prototype and produce on-demand parts enables companies like Boeing and Airbus to reduce costs and improve supply chain efficiency. Additionally, additive manufacturing supports the production of spare parts on demand, eliminating the need for extensive inventories.

2. Automotive

The automotive industry has seen substantial benefits from 3D printing, particularly in terms of rapid prototyping, custom parts, and short-run production. Companies like Ford and BMW use 3D printing for prototyping new car models and creating tools and fixtures for manufacturing. Not only does this shorten the product development cycle, but it also enables customization and cost-effective production of low-volume or specialty parts. Strati, a car made by Local Motors, is a notable example of a vehicle produced almost entirely through 3D printing.

3. Medical

In the medical field, additive manufacturing is enabling personalized medicine. Surgeons can create custom prosthetics, implants, and surgical guides tailored to individual patients, improving the fit, comfort, and functionality of these devices. Bioprinting—the process of printing living tissues and organs—also holds promise for future medical applications. At the Mayo Clinic, for instance, 3D printing has been used to create custom surgical guides for patient-specific procedures, improving surgical precision and reducing recovery times.

4. Consumer Goods

The consumer goods industry is increasingly embracing 3D printing to deliver customized products and to streamline production processes. For example, Adidas uses 3D printing to create custom footwear tailored to the individual shape and needs of the consumer's feet. Nike has also ventured into 3D printing to produce custom performance-enhancing shoe features. Other industries, such as fashion, jewelry, and home decor, are exploring the potential for limited-edition products and bespoke designs that can be produced quickly and affordably.

Case Studies and Success Stories

Industry-Specific Examples

- Aerospace: GE Aviation uses additive manufacturing to create fuel nozzles for jet engines, which are significantly lighter and more durable than traditional counterparts, leading to improved fuel efficiency and lower operating costs.

- Automotive: Local Motors manufactured the Strati, the world’s first 3D-printed car, which was built with 3D-printed components, demonstrating the potential for fully printed vehicles.

- Medical: Mayo Clinic utilized 3D printing to create patient-specific surgical guides, enabling more accurate surgeries and faster recovery times.

- Consumer Goods: Nike has developed 3D-printed shoes that offer a customized fit, providing athletes with shoes that better support their individual needs and enhance their performance.

Impact on Product Development

Additive manufacturing allows for faster prototyping and iterative design, leading to a more efficient product development cycle. By enabling rapid testing of multiple designs, engineers and designers can quickly identify the best options and bring them to market faster. This has been particularly beneficial for industries like automotive, where constant innovation is required to stay competitive.

Conclusion and Outlook

Summary of Key Points

Additive manufacturing services offer a wide range of benefits, including time and cost efficiency, design flexibility, and material optimization. Its ability to create complex geometries and produce custom parts quickly has led to its adoption in industries such as aerospace, automotive, medical, and consumer goods. The ability to prototype rapidly and manufacture on demand has reshaped how companies approach product development and manufacturing.

Projections for Growth and Innovation

The future of additive manufacturing is promising. With continuous advancements in materials and printer capabilities, as well as broader adoption across industries, additive manufacturing is expected to play an increasingly critical role in the future of manufacturing. Hybrid manufacturing, which combines 3D printing with traditional manufacturing processes, is also on the rise, offering even more possibilities for innovation. New materials—such as stronger metals, biocompatible materials for medical applications, and eco-friendly plastics—will continue to expand the reach and capabilities of additive manufacturing.

FAQs

What are the primary benefits of additive manufacturing services?

- Time and Cost Efficiency: Reduces production time and costs by eliminating the need for tooling and molds.

- Design Flexibility: Enables the creation of complex geometries that would be difficult or impossible to achieve with traditional methods.

- Material Optimization: Minimizes material waste, which is particularly important in high-cost material industries like aerospace and medical.

How is additive manufacturing impacting product development?

Additive manufacturing accelerates product development by allowing for rapid prototyping and iteration. This enables engineers to quickly test and refine designs, reducing the time-to-market and increasing the potential for innovative solutions.

What are some future trends in additive manufacturing?

- Advanced Materials: New materials with enhanced properties such as strength, heat resistance, and biocompatibility.

- Hybrid Manufacturing: Combining 3D printing with traditional manufacturing methods to create more efficient and cost-effective solutions.

- Expansion into New Industries: Broader applications in sectors like construction, electronics, and even food production, as the technology matures and becomes more accessible.