Introduction to Additive Manufacturing

Additive manufacturing (AM), also known as 3D printing, has fundamentally altered the landscape of production and manufacturing. Unlike traditional subtractive manufacturing methods, which involve removing material from a larger mass, additive manufacturing builds up objects layer by layer from a digital model. This approach has brought numerous benefits across various industries but also presents unique challenges. In this article, we will explore the key advantages and limitations of additive manufacturing technologies, providing an overview of their current capabilities and potential for future developments.

Definition and History

What is Additive Manufacturing?

Additive manufacturing refers to the process of creating three-dimensional objects from a digital file by successively adding material layer upon layer. In contrast to traditional methods, which subtract material from larger blocks, AM builds the object incrementally. This process can use a variety of materials such as plastics, metals, ceramics, and even biological substances. The ability to produce complex shapes and geometries with high precision makes AM especially valuable in industries requiring intricate parts and custom solutions.

A Brief History

Additive manufacturing originated in the 1980s when Charles "Chuck" Hull invented stereolithography (SLA), the first commercial 3D printing process. Since then, many other techniques have emerged, including Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Electron Beam Melting (EBM). These developments have expanded the applications of AM across a wide range of industries, including aerospace, automotive, healthcare, and consumer goods.

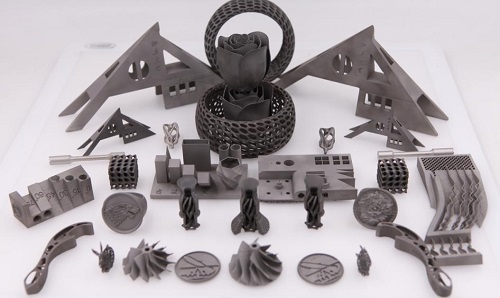

Types of Additive Manufacturing Processes

Several additive manufacturing techniques are in use today, each suited to specific applications:

1. Stereolithography (SLA)

SLA utilizes a UV laser to solidify a photopolymer resin layer by layer. Known for its ability to produce high-resolution parts with smooth finishes, SLA is often used for creating intricate models and prototypes.

2. Selective Laser Sintering (SLS)

SLS uses a laser to fuse powdered material, such as nylon or polycarbonate, into a solid form. This method is valued for creating durable, functional prototypes and parts without the need for support structures.

3. Fused Deposition Modeling (FDM)

FDM works by extruding thermoplastic filament through a heated nozzle, where the material is deposited layer by layer. FDM is widely used due to its simplicity and affordability, making it suitable for prototyping and small-scale production.

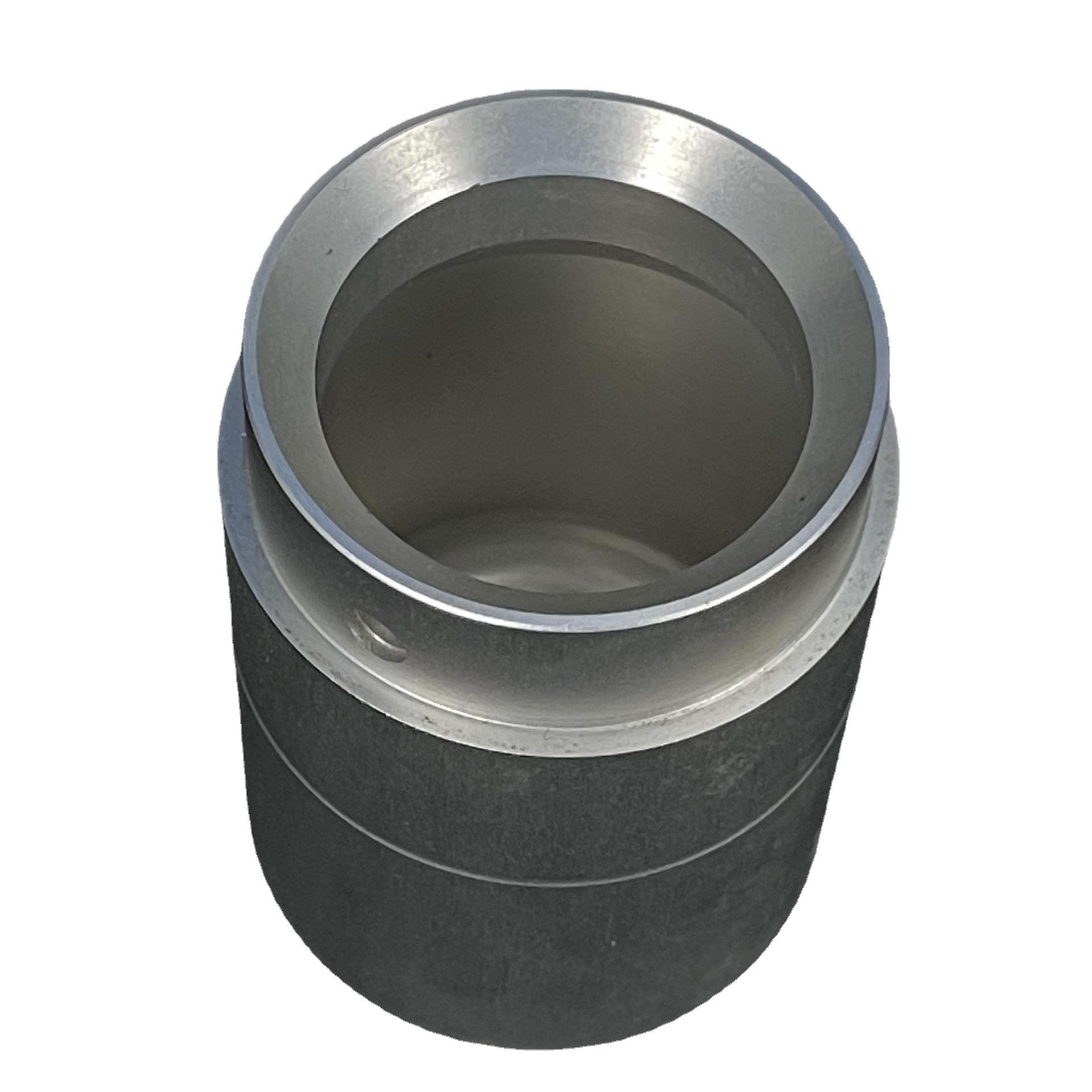

4. Electron Beam Melting (EBM)

EBM utilizes an electron beam to melt metal powder in a vacuum environment. This technique is particularly useful for creating complex metal parts with high strength and precision, commonly used in aerospace and medical applications.

5. Binder Jetting

Binder jetting involves selectively depositing a liquid binder to bond powdered material, such as metal or sand. This process is commonly used for creating molds and cores in industries like foundries.

Advantages of Additive Manufacturing

Reduced Production Time and Cost

Additive manufacturing significantly reduces the time and cost associated with traditional manufacturing. With AM, businesses can rapidly prototype and produce products, eliminating the need for expensive tooling and reducing labor costs. The ability to create complex parts without molds or casting also lowers production costs.

Design Flexibility and Complexity

AM allows for the creation of complex geometries that would be difficult or impossible to achieve using traditional manufacturing methods. Designers can take advantage of this flexibility to optimize product designs, reduce weight, and improve functionality. Parts with intricate internal structures, such as lattice designs, are particularly suited for AM.

On-Demand and Customizable Production

AM enables on-demand production, meaning parts are made only when needed, reducing the need for large inventories and minimizing storage costs. This capability is particularly beneficial for industries that require customization, such as medical devices or consumer electronics, where products can be tailored to individual specifications. This customization leads to reduced waste and enhanced customer satisfaction.

Limitations of Additive Manufacturing

Material Limitations

Despite the wide range of materials available, additive manufacturing still faces limitations in material properties. For example, some polymers may degrade under high temperatures or UV exposure, while metals might lack the mechanical strength required for certain applications. Although material development is advancing rapidly, some industries still require materials that AM cannot fully replicate in terms of performance or durability.

Build Time and Speed

While additive manufacturing can be faster than traditional methods for small-scale production and prototyping, the layer-by-layer process can be time-consuming for larger or more complex parts. As such, for mass production, AM is often less efficient than traditional manufacturing processes. Efforts to improve printing speeds, such as the use of multiple lasers or more efficient algorithms, are ongoing, but build time remains a consideration.

Strength and Durability Concerns

Parts created using additive manufacturing may not always have the same strength and durability as those made through traditional methods. The layered nature of AM can result in weaker bond lines, which might affect the material’s overall mechanical properties. Post-processing, such as heat treatment or surface finishing, is often required to improve the strength and appearance of AM parts.

Applications of Additive Manufacturing

Aerospace and Automotive Industries

Additive manufacturing plays a crucial role in aerospace and automotive industries by enabling the production of lightweight, complex components. AM reduces weight and increases fuel efficiency in aircraft and vehicles by optimizing designs that are difficult or impossible to create using conventional manufacturing methods. Companies like Boeing, General Electric, and Ford have successfully integrated AM into their production lines to enhance performance and reduce costs.

Medical and Dental Applications

AM is increasingly used in the medical and dental fields, particularly for customized solutions. 3D-printed prosthetics, implants, and surgical guides are tailored to an individual’s specific anatomy, improving fit and comfort. In dentistry, AM enables the creation of custom dental crowns and bridges with high precision. These innovations have led to better patient outcomes and more efficient healthcare solutions.

Consumer Goods and Art

Additive manufacturing also finds applications in consumer goods and the art world, where customization and creativity are key. Artists and designers use AM to produce unique sculptures, jewelry, and personalized products. Consumers can create customized phone cases, footwear, or home decor to suit their preferences. This has led to a more personalized approach to product development, providing consumers with exactly what they want.

FAQs

Q1: What materials can be used in additive manufacturing?

A1: Additive manufacturing supports a wide range of materials, including plastics (ABS, polycarbonate, nylon), metals (titanium, aluminum), ceramics, composites, and even biological materials. Research into new materials is ongoing, allowing AM to continue expanding into more industries with higher performance requirements.

Q2: How accurate is additive manufacturing?

A2: The accuracy of additive manufacturing depends on the specific process and equipment used. Generally, AM can achieve tolerances within ±0.1% to ±0.5%. High-precision methods like SLA and EBM can achieve even tighter tolerances. Post-processing techniques can also enhance accuracy and surface finish.

Q3: Is additive manufacturing cost-effective for mass production?

A3: Additive manufacturing is ideal for prototyping and low-volume production, but it can be less cost-effective than traditional methods for high-volume mass production. However, as AM technology evolves and economies of scale improve, it may become more competitive for larger production runs. Currently, AM is most cost-effective for creating complex, customized parts.

In conclusion, additive manufacturing technologies offer significant advantages in terms of design flexibility, reduced production time, and the ability to produce customized, on-demand products. While the technology has limitations, particularly in material properties and production speed, ongoing research and development are expanding its capabilities. As these technologies continue to mature, their impact across industries will only grow, bringing more innovative solutions to the manufacturing world.