Understanding the Basics of 3D Printing

3D printing, also known as additive manufacturing, has revolutionized the way we create three - dimensional objects. Instead of subtracting material from a larger block like in traditional manufacturing methods, 3D printing builds objects layer by layer from the bottom up.

The process starts with a digital 3D model, which is usually created using computer - aided design (CAD) software. This model is then sliced into thin cross - sectional layers by specialized software. The 3D printer reads these sliced files and deposits materials such as plastics, metals, ceramics, or even biological materials (in the case of bioprinting) layer by layer to gradually form the final object.

3D printing has found applications in a vast array of industries:

- Manufacturing: It is widely used for rapid prototyping. For example, automotive companies can quickly create prototypes of new car parts to test their functionality and design before mass production. According to a study by Wohlers Associates, the global 3D printing market in the manufacturing sector was valued at $4.4 billion in 2022 and is expected to grow at a CAGR of 20.4% from 2023 - 2028. This technology also enables the production of customized and complex - shaped parts that are difficult to manufacture through traditional methods.

- Medical: In the medical field, 3D printing has enabled the creation of patient - specific implants. For instance, doctors can use 3D - printed prosthetics that are tailored to fit an individual's body perfectly. In 2022, the medical 3D printing market was worth $1.7 billion. It has also made significant inroads in dental applications, such as creating custom - fit dental crowns and bridges.

- Architecture: Architects use 3D printing to build detailed models of their designs. This not only helps in visualizing the final structure but also in communicating the design concept to clients. Some companies are even exploring the possibility of 3D - printing entire buildings. A 3D - printed house in Amsterdam was completed in 2017, demonstrating the potential of this technology in the construction industry.

How to Find the Right 3D Printing Business Near You

Finding the right 3D printing business near you can be a crucial step, whether you're a hobbyist, a small - business owner, or a large - scale manufacturer. Here are some effective ways to identify the best 3D printing service for your needs.

Online Search

The internet is a powerful tool for finding local 3D printing businesses. Start by using popular search engines like Google. Enter keywords such as “3D printing business near me”, “local 3D printing services”, or more specific terms like “3D printing for jewelry making near me” if you have a particular application in mind.

Business directories can also be very helpful. Platforms like Yelp, Yellow Pages, and Angie's List often list 3D printing services along with customer reviews and ratings. For example, on Yelp, you can find detailed reviews of 3D printing shops in your area, including comments on the quality of their prints, customer service, and pricing.

Reviews and Testimonials

Customer reviews and testimonials are invaluable when evaluating a 3D printing business. They provide real - world insights into the quality of service, the accuracy of prints, and the overall customer experience. Look for reviews on multiple platforms, including the business's own website, Google My Business, and industry - specific forums.

For instance, if a 3D printing business has consistently high ratings on Google My Business with comments praising the precision of their prints and their quick turnaround times, it's a positive sign. On the other hand, if there are multiple complaints about poor - quality prints or unresponsive customer service, it's a red flag. Also, check for testimonials from clients with similar projects to yours. If you're in the automotive industry and find a testimonial from an automotive company that had a great experience with a local 3D printer, it's more likely that the business can meet your needs.

Visiting in Person

Visiting a 3D printing business in person can give you a firsthand look at their operations. When you visit, pay attention to the following aspects:

- Equipment: Check the types of 3D printers they have. A diverse range of printers, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) printers, indicates that they can handle different materials and project requirements. For example, an SLA printer is great for producing high - resolution, detailed models, while an SLS printer can work with a wider range of materials, including nylon.

- Work Environment: A clean and organized workspace often reflects a professional and efficient operation. Observe how they store their materials and how well - maintained their equipment is. If the printers look dirty or poorly maintained, it could potentially affect the quality of your prints.

- Staff Knowledge: Engage with the staff and assess their knowledge. They should be able to answer your questions about different printing processes, materials, and any specific requirements you may have. A knowledgeable staff can also offer valuable advice on how to optimize your design for 3D printing.

Comparing 3D Printing Services

Types of Materials Offered

When choosing a 3D printing service, the types of materials available are crucial. Here is a comparison of common 3D printing materials:

| Material | Characteristics | Applicable Scenarios | Approximate Price per Kilogram (USD) |

| PLA (Polylactic Acid) | Biodegradable, easy to print, low - temperature processing, relatively low strength | Prototyping, small - scale production, decorative items | 15 - 20 |

| ABS (Acrylonitrile Butadiene Styrene) | High strength, heat - resistant, good for post - processing like sanding and painting, but may warp during printing | Automotive parts prototyping, consumer electronics housings | 18 - 25 |

| PETG (Polyethylene Terephthalate Glycol) | Combines the advantages of PLA and ABS, high durability, strong, and suitable for food - contact applications | Food containers, mechanical parts with high - strength and transparency requirements | 20 - 30 |

| Nylon | Exceptionally strong and tough, highly wear - resistant, and chemically resistant | Industrial parts that endure long - term mechanical stress, such as gears | 30 - 50 |

| Metal (e.g., Stainless Steel, Titanium Alloy) | High strength, excellent heat - resistance, and high precision | Aerospace components, medical implants, high - end tooling | 2000 - 5000 (for metal powders) |

| Ceramic | High - temperature resistance, hardness, and chemical stability | High - temperature applications like furnace linings, and artistic sculptures | 50 - 200 |

Printing Technologies

There are several 3D printing technologies, each with its own set of advantages and limitations:

- FDM (Fused Deposition Modeling): This technology melts and extrudes filament - like materials layer by layer. Advantages: It is relatively low - cost, the equipment is easy to operate, and a wide range of materials can be used. For example, it is a popular choice for hobbyists and small - scale businesses due to its simplicity. Disadvantages: The surface finish is usually not very smooth, and the printing speed can be slow. It is best suited for creating prototypes and functional parts where high precision is not the top priority.

- SLA (Stereolithography): SLA uses a laser to cure liquid resin layer by layer. Advantages: It offers high - resolution prints with smooth surfaces, making it ideal for creating detailed models, jewelry, and dental prosthetics. Disadvantages: The equipment and resin materials can be expensive, and the resin is often toxic, requiring proper ventilation.

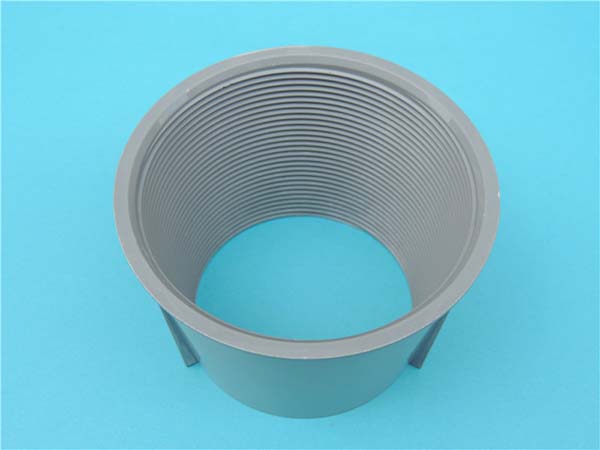

- SLS (Selective Laser Sintering): SLS uses a laser to sinter powdered materials. Advantages: It can work with a variety of materials including metals, ceramics, and plastics, and it doesn't require support structures as the unsintered powder supports the part during printing. It is suitable for manufacturing complex - shaped parts for industrial applications. Disadvantages: The surface of the printed parts may be rough, and the equipment is costly.

Pricing Structures

The pricing of 3D printing services depends on multiple factors:

- Material Cost: As shown in the materials table above, different materials have different costs. For instance, printing with metal powders will be much more expensive than using PLA.

- Printing Time: Longer printing times increase the cost. Complex models with large volumes or high - detail requirements take more time to print. For example, a large - scale architectural model may take days to print, driving up the cost.

- Model Complexity: Models with intricate geometries, such as those with many small details, internal cavities, or overhangs, often require more support structures and longer printing times. They may also need more post - processing, all of which contribute to a higher price.

Let's take a look at a simple pricing comparison example. Suppose we want to print a small cube with a side length of 5 cm.

| 3D Printing Service Provider | Material Used | Estimated Price (USD) |

| Provider A | PLA | 5 |

| Provider B | ABS | 8 |

| Provider C | PETG | 10 |

This shows how material choice can significantly impact the cost even for a simple model.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology highly values the development of 3D printing business nearby. We believe that local 3D printing services can significantly enhance the flexibility and efficiency of product development.

At Yigu Technology, we have a rich variety of materials at our disposal. Whether it's high - performance plastics for lightweight and corrosion - resistant parts or special metal alloys for applications demanding high strength and heat resistance, we can meet diverse needs. Our advanced 3D printing technology ensures high - precision and high - quality production. We can handle complex geometries with ease, providing customized solutions for every client.

For example, when a client in the automotive industry needed a custom - designed plastic component with intricate internal channels for heat dissipation, our 3D printing technology enabled us to produce a prototype quickly. The component was then tested and optimized, reducing the overall development time by nearly 40% compared to traditional manufacturing methods.

We also pride ourselves on our comprehensive custom - service. From the initial design consultation to the final product delivery, our professional team offers one - stop support. We work closely with clients to understand their unique requirements, making adjustments to the design and production process to ensure the final product is exactly what they envision. This personalized service sets us apart in the 3D printing market.