Introduction

Additive manufacturing, commonly known as 3D printing, is a revolutionary manufacturing process that creates three - dimensional objects by adding material layer by layer, as opposed to subtractive manufacturing methods that remove material. This technology has transformed various industries due to its ability to produce complex geometries, reduce waste, and enable rapid prototyping.

There are seven main types of additive manufacturing, each with its unique principles, materials, and applications: Powder Bed Fusion (PBF), Directed Energy Deposition (DED), Vat Photopolymerization, Binder Jetting, Material Extrusion, Material Jetting, and Sheet Lamination. In the following sections, we will explore each type in detail, comparing their features, advantages, and limitations to help you understand which might be best for your specific needs.

The 7 Types of Additive Manufacturing

Sheet Lamination

Sheet Lamination works by bonding thin layers of material, such as paper, plastic, or metal, together to form a 3D object. Each layer is cut into the desired shape using a laser or a mechanical cutter, and then stacked and bonded. An example of this technology is Laminated Object Manufacturing (LOM). This method is often used for creating large - scale prototypes, architectural models, and even some low - cost manufacturing applications due to its relatively simple process and ability to handle large parts.

Direct Energy Deposition (DED)

Direct Energy Deposition uses a high - energy source, such as a laser or an electron beam, to melt and deposit materials directly onto a substrate. Materials are fed into the energy beam in the form of powder or wire. Two key technologies in this category are Laser Engineered Net Shaping (LENS) and Electron Beam Additive Manufacturing (EBAM). LENS typically uses a laser as the energy source and is suitable for creating complex, high - precision parts, often in small to medium sizes. EBAM, on the other hand, uses an electron beam and can produce much larger parts, which is beneficial for industries like aerospace where large - scale components are required. The main difference between them lies in the energy source and the scale of the parts they can produce.

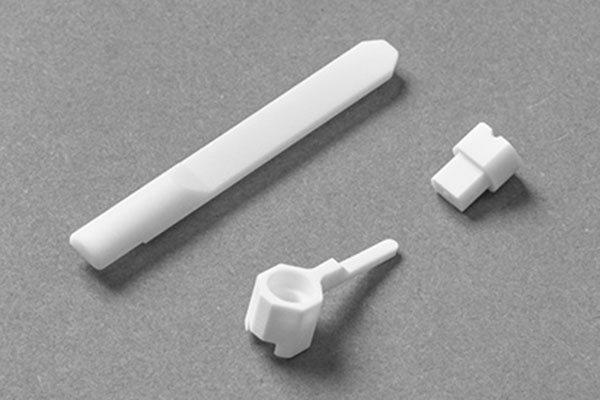

Material Extrusion

Material Extrusion involves pushing a material, usually a thermoplastic filament, through a nozzle. The material is melted as it passes through the nozzle and is deposited layer by layer according to the design. Two well - known processes in this type are Fused Deposition Modelling (FDM) and Fused Filament Fabrication (FFF), which are essentially the same process with different names. In the process, the printer head moves in the X - Y plane while extruding the molten material, and the build platform moves in the Z - axis to create the height of the object. This method is popular for hobbyists, educational institutions, and low - cost prototyping due to its simplicity and the wide range of available materials, such as ABS, PLA, and PETG.

Material Jetting

Material Jetting ejects small droplets of liquid material, such as resin or wax, onto a build platform. The droplets are precisely deposited to form each layer of the object. This process often uses materials that can be cured quickly, for example, through ultraviolet light. Nano Particle Jetting (NPJ) and Drop - on - demand (DOD) are techniques within this category. NPJ is known for its high - precision deposition of nano - scale particles, while DOD ejects droplets only when needed, which allows for more efficient use of materials. This technology is suitable for applications that require high - resolution and detailed parts, such as jewelry making and micro - mechanical components.

Binder Jetting

Binder Jetting selectively deposits a liquid binder onto a bed of powder material, such as metal, ceramic, or sand. The binder bonds the powder particles together to form the desired shape layer by layer. One notable technology is HP METAL JET TECHNOLOGY. After the printing process, the part often needs post - processing. Commonly used post - processing materials include infiltrants like bronze for metal - based parts, which can improve the strength and density of the final product. This method is great for creating large - scale parts and is also cost - effective for high - volume production of simple parts.

Vat Photopolymerization

Vat Photopolymerization cures liquid photopolymer resin using light. There are three main techniques based on different light sources: Stereolithography (SLA), which uses a focused laser beam to cure the resin layer by layer; Direct Light Processing (DLP), which uses a digital light projector to cure an entire layer at once, resulting in faster printing; and Continuous Direct Light Processing (CDLP), which is an improvement over DLP, enabling continuous curing and even faster production. These technologies are widely used in applications where high - precision and smooth - surface finishes are required, such as dental prosthetics, jewelry casting, and the production of small, intricate parts.

Powder Bed Fusion (PBF)

Powder Bed Fusion selectively heats and fuses regions of a powder bed using a heat source, such as a laser or an electron beam. This category includes Selective Laser Sintering (SLS), which sinters powder materials (usually plastics or composites); Selective Laser Melting (SLM), which fully melts metal powders to create dense, high - strength parts; Direct Metal Laser Sintering (DMLS), similar to SLM but often used for more complex metal parts; and Electron Beam Melting (EBM), which uses an electron beam in a vacuum environment to melt metal powder. These processes are highly valued in industries like aerospace, automotive, and medical, where high - strength, complex - shaped metal parts are essential.

Comparison Table

Here is a comparison table summarizing the key characteristics of the seven types of additive manufacturing:

| Type | Materials | Speed | Precision | Cost (Equipment & Materials) | Complexity of Parts | Applications |

| Sheet Lamination | Paper, plastic, metal | Moderate - Slow | Low - Moderate | Low - Moderate | Low - Moderate | Large - scale prototypes, architectural models |

| Direct Energy Deposition | Metal powder, wire | Slow - Moderate | Low - Moderate | High | High | Aerospace, large - scale components |

| Material Extrusion | Thermoplastic filaments (e.g., ABS, PLA, PETG) | Slow | Low - Moderate | Low | Low - Moderate | Hobbyist projects, educational use, low - cost prototyping |

| Material Jetting | Liquid resin, wax | Slow - Moderate | High | High | High | Jewelry making, micro - mechanical components |

| Binder Jetting | Metal, ceramic, sand powder | Fast | Low - Moderate | Moderate - High | High | Large - scale parts, high - volume production of simple parts |

| Vat Photopolymerization | Liquid photopolymer resin | Slow - Fast (depending on technique) | High | Moderate - High | High | Dental prosthetics, jewelry casting, small intricate parts |

| Powder Bed Fusion | Metal, plastic, composite powders | Slow - Moderate | High | High | High | Aerospace, automotive, medical |

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology highly values the role of these seven types of additive manufacturing technologies. These technologies have brought great convenience to custom production. For plastic products, material extrusion can be a cost - effective choice for creating prototypes with common plastic filaments like ABS and PLA. When it comes to metal products, powder bed fusion technologies such as SLM and DMLS can produce high - strength, complex - shaped metal parts. We believe that by understanding the characteristics of these different additive manufacturing technologies, we can better meet the diverse needs of customers, providing more accurate, efficient, and high - quality custom - made products.