Introduction to SLA 3D Printing

Stereolithography (SLA) 3D printing is a cutting-edge technology that has significantly impacted industries that require high-resolution and precise prototyping. SLA utilizes a laser to cure liquid photopolymer resin layer by layer, producing parts with extraordinary detail and smooth surface finishes. This technology is known for its ability to handle complex designs, intricate geometries, and delicate features with remarkable accuracy. In this article, we’ll explore the key features, benefits, and applications of SLA 3D printing services, and compare them to other 3D printing technologies.

Definition and Technology Overview

What is SLA 3D Printing?

Stereolithography (SLA) is an additive manufacturing process that uses a laser to solidify a photopolymer resin layer by layer, based on a 3D CAD model. A vat filled with liquid resin is exposed to ultraviolet (UV) light, which cures each layer as the laser traces out the shape of the object. The process continues, layer by layer, until the complete object is formed. The precision of this method allows for the creation of highly detailed and intricate designs.

How Does SLA Work?

- Design Preparation: A 3D object is designed using CAD software, which is then converted into an STL file that breaks the object into horizontal layers.

- Resin Application: A build platform is lowered into a vat of liquid resin.

- Laser Scanning: A UV laser scans the surface of the resin, curing it layer by layer.

- Layer Formation: After one layer is cured, the platform lowers slightly, and a new layer of resin is applied.

- Repeat Process: Steps 3 and 4 are repeated until the object is fully formed.

- Post-Processing: The printed object is removed from the build platform and excess resin is cleaned off. It may then undergo curing under UV light, sanding, or painting for a finished look.

Key Features of SLA 3D Printing Services

1. High Resolution and Detail

One of the standout features of SLA 3D printing is its exceptional resolution. SLA printers can achieve layer resolutions as fine as 0.025 mm, resulting in smooth surfaces and intricate details. This makes SLA ideal for applications that demand precision, such as medical devices, aerospace components, and jewelry design. The fine resolution means that the printed object can capture complex geometries and delicate features with ease.

2. Layer-by-Layer Precision

SLA 3D printing produces objects layer by layer with exceptional accuracy. Each layer adheres seamlessly to the previous one, resulting in a high degree of precision. The laser ensures that each layer is precisely cured, contributing to the structural integrity of the final product. This capability makes SLA perfect for applications that require complex internal structures or features that would be difficult or impossible to create using traditional methods.

3. Material Versatility

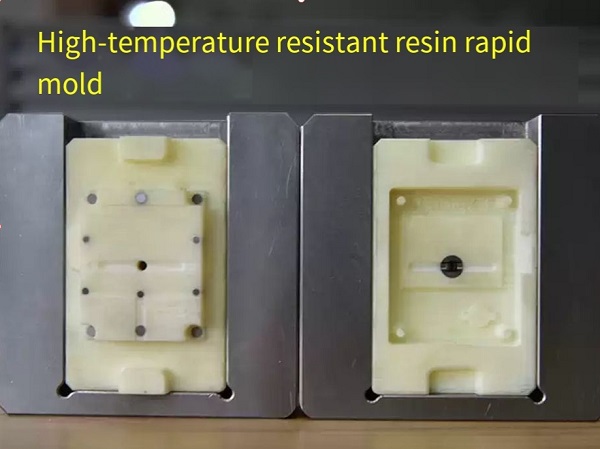

SLA printing supports a wide range of materials, offering various properties such as flexibility, strength, heat resistance, and biocompatibility. These include:

- Standard Photopolymer Resins: For general-purpose prototyping.

- Engineering-grade Resins: For parts that require specific mechanical properties.

- Dental Resins: For producing dental models, crowns, and bridges.

- Biocompatible Resins: For medical devices and implants.

- Casting Resins: Used for making molds for metal casting.

The ability to use specialized resins makes SLA highly versatile and adaptable to different industries.

Benefits of SLA 3D Printing

1. Accuracy and Surface Finish

SLA is renowned for producing parts with minimal layer lines and an excellent surface finish. The precision of the laser and the use of liquid resin result in parts with smooth surfaces, often requiring little to no post-processing. This is particularly beneficial for industries where surface finish is critical, such as in aerospace or consumer product design.

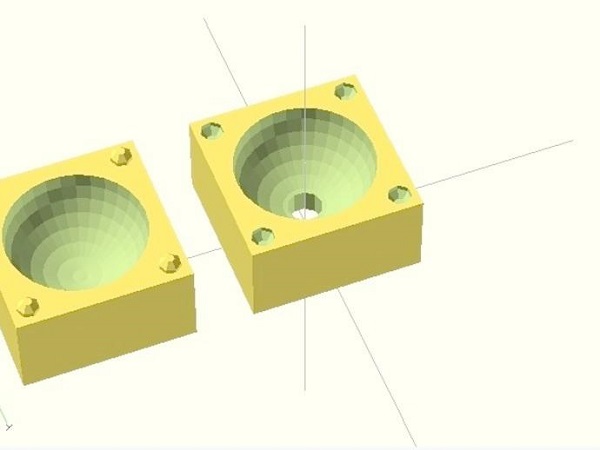

2. Complex Geometry Capability

SLA 3D printing excels in creating complex geometries that would be difficult, if not impossible, to produce with traditional manufacturing methods. The process does not require tooling or molds, making it easier to create intricate parts with internal structures, undercuts, and thin features. This design freedom is a major advantage for engineers and designers, enabling them to push the boundaries of what’s possible in product development.

3. Rapid Prototyping and Small Batch Production

SLA is a fast and cost-effective method for rapid prototyping. It allows designers and engineers to quickly produce high-quality prototypes for testing, validation, and iteration. This speed is crucial in industries where time-to-market is a competitive advantage. Furthermore, SLA is well-suited for small batch production, making it ideal for industries that require low-volume, custom, or highly detailed parts, such as medical implants or luxury goods.

Applications of SLA 3D Printing

1. Automotive Industry

In the automotive sector, SLA 3D printing is widely used for creating concept models, functional prototypes, and lightweight components. The high resolution allows for the development of detailed interior parts, functional assemblies, and design iterations that are tested for aerodynamics, fit, and form. SLA is especially beneficial in producing parts that require precision engineering or complex geometry.

2. Aerospace Sector

The aerospace industry benefits from SLA 3D printing’s ability to produce high-strength, lightweight parts with intricate designs. SLA is used to prototype aircraft components, engine parts, and tools. The material choices available also allow for parts that meet specific aerospace standards, including heat resistance and durability. SLA’s precision makes it suitable for parts that need to meet rigorous tolerances for aerodynamic performance and safety.

3. Medical Field

SLA 3D printing is making a profound impact in the medical field. The high resolution allows for the production of patient-specific implants, prosthetics, surgical guides, and anatomical models for planning complex surgeries. Certain biocompatible resins are FDA-approved for use in medical applications, making SLA an ideal choice for creating devices that come into direct contact with the human body.

4. Consumer Products

SLA is increasingly used in the production of customized consumer goods, such as jewelry, fashion accessories, and toys. The ability to create intricate designs with high precision allows companies to produce unique, bespoke products that stand out in a competitive market. Additionally, SLA is ideal for creating models or mockups of consumer products before going into full-scale production.

Comparison with Other 3D Printing Technologies

SLA vs. FDM (Fused Deposition Modeling)

FDM and SLA are both popular 3D printing technologies, but they differ significantly:

- Resolution and Surface Finish: SLA offers a much higher resolution and smoother surface finish compared to FDM, which often produces more visible layer lines.

- Material Options: FDM uses thermoplastic filaments, which may not offer the same material properties as the photopolymer resins used in SLA.

- Speed: FDM is often faster for larger parts but lacks the fine detail SLA provides.

- Applications: SLA is better for highly detailed, precise parts, while FDM is often used for functional prototypes or larger, less intricate parts.

SLA vs. DLP (Digital Light Processing)

Both SLA and DLP use light to cure resin, but they differ in their approach:

- SLA uses a laser to cure resin layer by layer, making it more precise, especially for fine details.

- DLP uses a digital light projector to flash an entire layer at once, making it faster than SLA for certain applications but often less precise, especially for intricate features.

- Applications: SLA is preferred for applications requiring high detail and precision, while DLP is suited for quicker, less detailed production.

FAQs

Q1: What materials can be used in SLA 3D printing?

A1: SLA supports a wide range of materials, including standard photopolymer resins, engineering-grade resins, dental resins, medical-grade resins, and casting resins. These materials offer various properties like flexibility, strength, heat resistance, and biocompatibility, making SLA versatile for many industries.

Q2: How accurate is SLA 3D printing?

A2: SLA 3D printing is known for its high accuracy, with layer resolutions as fine as 0.025 mm. The laser precision ensures that each layer is accurately cured, resulting in smooth surfaces and fine details, making it ideal for applications requiring exact geometries and complex designs.

Q3: What are the main benefits of SLA 3D printing over other 3D printing technologies?

A3: SLA provides benefits such as high resolution, excellent surface finish, complex geometry capability, and material versatility. These features make SLA ideal for industries like medical, aerospace, and automotive, where precision and the ability to produce intricate parts are critical.

SLA 3D printing services offer exceptional accuracy, detail, and material options that are valuable across multiple industries. Whether you’re in automotive, medical, aerospace, or consumer products, SLA can deliver high-quality prototypes and end-use parts that push the boundaries of innovation and design.