Understanding STL Format in 3D Printing

In the fascinating realm of 3D printing, the STL format stands as a cornerstone. It serves as the crucial link that bridges the gap between the digital models meticulously crafted in the virtual world of 3D design software and the tangible, physical objects that are brought to life through the magic of 3D printing technology.

What is STL Format?

STL, short for “Standard Tessellation Language,” is a file format widely utilized in 3D printing. It describes the surface geometry of a three - dimensional object through a triangular mesh. Imagine you have a complex 3D model of a human skull. The STL format breaks down the smooth surface of this skull model into a vast number of tiny triangles. These triangles, when combined, approximate the shape of the original object. Each triangle is defined by three vertices in three - dimensional space. For example, if we consider a simple cube in 3D space, its STL file would contain a set of triangles that make up each face of the cube. This triangulation method allows the 3D printer to understand the shape and structure of the object precisely, as it can interpret these simple geometric primitives (triangles) and use them to build the object layer by layer during the 3D printing process.

Its Significance in 3D Printing

The STL format holds the status of an industry - standard format in 3D printing. It is an essential part of the 3D printing workflow. Virtually all 3D modeling software, ranging from professional - grade tools like Blender, Maya, and 3ds Max to more beginner - friendly options such as Tinkercad, support the export of models in STL format. This universality means that regardless of which software you use to create your 3D design, you can easily convert it into a format that can be used by 3D printers.

On the printer side, nearly every 3D printer, whether it's a low - cost desktop FDM (Fused Deposition Modeling) printer like the Creality Ender series or a high - end industrial SLA (Stereolithography Apparatus) printer, is designed to accept STL files as input. Without the STL format, the seamless transfer of 3D models from the design stage to the printing stage would be extremely difficult, if not impossible. It enables designers, hobbyists, and manufacturers to share 3D models across different platforms and devices, making 3D printing accessible and efficient.

The Process of STL Format 3D Printing

Understanding the process of STL format 3D printing is crucial for anyone looking to dive into the world of 3D printing. This process is like a well - choreographed dance, with each step being essential for a successful outcome.

3D Modeling and STL Export

The journey begins with 3D modeling. You can use a plethora of 3D modeling software. For instance, if you are into character creation, Blender or Maya might be your go - to tools. Blender, being open - source, is a favorite among hobbyists and indie developers. To create a 3D model, you start by defining the basic shape, like building a simple cube as a base for a more complex structure. Then, you gradually add details, such as smoothing the edges, adding textures, and defining the object's dimensions.

Once the model is complete, it's time to export it as an STL file. When exporting, pay close attention to the settings. The tolerance setting is crucial. A low tolerance value will result in a more accurate representation of the model, with smaller triangles approximating the surface more precisely. However, this can also lead to a larger file size. On the other hand, a high tolerance value will create a coarser approximation with fewer triangles, reducing the file size but potentially sacrificing some details. For example, if you are creating a highly detailed jewelry model, you would want a low tolerance to capture all the fine details.

Slicing the STL File

After obtaining the STL file, the next step is slicing. This is where a slicing software, like Cura or PrusaSlicer, comes into play. The slicing software reads the STL file and slices the 3D model into multiple two - dimensional layers.

The slicing process involves several important parameters. The layer height is one of the most critical ones. A smaller layer height, such as 0.1mm, will result in a smoother surface finish but will increase the printing time as more layers need to be printed. In contrast, a larger layer height, like 0.3mm, will speed up the printing process but may lead to a more visible layer - by - layer appearance on the printed object. Another parameter is the infill density. A high infill density, say 100%, will make the printed object solid and sturdy but will also use more material and increase the weight. A lower infill density, like 20%, will save material and weight but may reduce the object's strength.

Printing with a 3D Printer

Finally, it's time for the 3D printer to work its magic. The 3D printer reads the G - code generated by the slicing software and starts the printing process.

There are different types of 3D printing technologies, each with its own compatibility with the STL format. FDM (Fused Deposition Modeling) printers are the most common desktop printers. They work by melting a filament (usually ABS or PLA) and extruding it layer by layer to build the object. FDM printers have no trouble handling STL files. SLA (Stereolithography Apparatus) printers use a laser to cure a photosensitive resin layer by layer. The STL file provides the precise geometry for the SLA printer to accurately create the object. SLS (Selective Laser Sintering) printers sinter powdered materials, such as nylon or metal powders, together. The STL format ensures that the SLS printer knows exactly where to fuse the powder particles to build the desired object. During the printing process, factors like the printer's temperature settings, the speed of the print head movement, and the adhesion of the printed layers to the build plate can all impact the final quality of the printed object.

Yigu Technology's Viewpoint

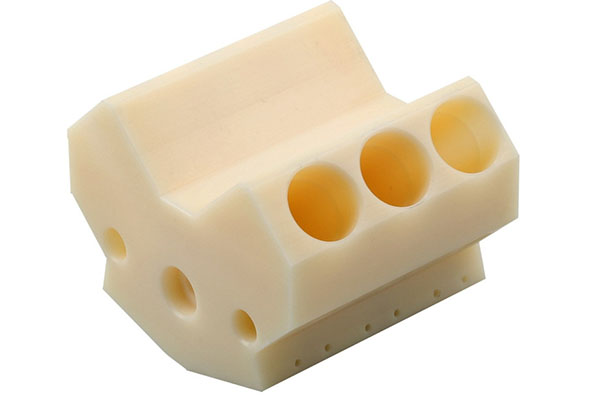

As a non - standard plastic metal products custom supplier, Yigu Technology highly values the role of STL format 3D printing. In our custom product development process, STL format 3D printing allows us to quickly create prototypes. By converting our digital designs into STL files and then printing them, we can physically visualize the product design at an early stage. This helps us to verify the design's feasibility, such as checking for any structural flaws or assembly issues. As a result, we can significantly shorten the product development cycle, saving both time and cost compared to traditional manufacturing methods.

Moreover, the ability to create complex structures with 3D printing using STL files is a huge advantage. It enables us to meet the unique and personalized needs of our customers. Whether it's a complex - shaped plastic part or a metal component with intricate internal structures, we can bring these designs to life. This not only enhances the functionality of the products but also gives our customers a competitive edge in the market.

FAQs about STL Format 3D Printing

Q1: Can I directly print an STL file on any 3D printer?

While the STL format is widely compatible with 3D printers, you can't directly print an STL file on any 3D printer without some considerations. Different 3D printers may have specific requirements regarding file parameters. For example, some printers may have limitations on the maximum file size they can handle. Additionally, the slicing settings need to be adjusted according to the printer's capabilities and the type of material being used. A low - cost FDM printer may require different layer height and infill settings compared to a high - end SLA printer. So, it's essential to check the printer's manual and adjust the settings accordingly before starting the print.

Q2: What factors should I consider when choosing the resolution of an STL file for 3D printing?

When choosing the resolution of an STL file for 3D printing, several factors come into play. First, consider the size of the printed object. A small, detailed object like a miniature figurine will require a higher resolution (smaller triangle size in the STL file) to capture all the fine details. On the other hand, a large, simple object such as a basic cube can be printed with a lower resolution without sacrificing much in terms of quality. The level of detail you want in the final printed product is also crucial. If you need a highly detailed surface finish, a higher - resolution STL file is necessary. Additionally, take into account the accuracy capabilities of your 3D printer. A printer with high precision can handle higher - resolution STL files better. Finally, the type of material you are using can influence the resolution choice. Some materials may not be able to accurately reproduce very fine details, so a very high - resolution STL file may not be necessary in such cases.