Introduction to 3D Printed Aircraft Parts

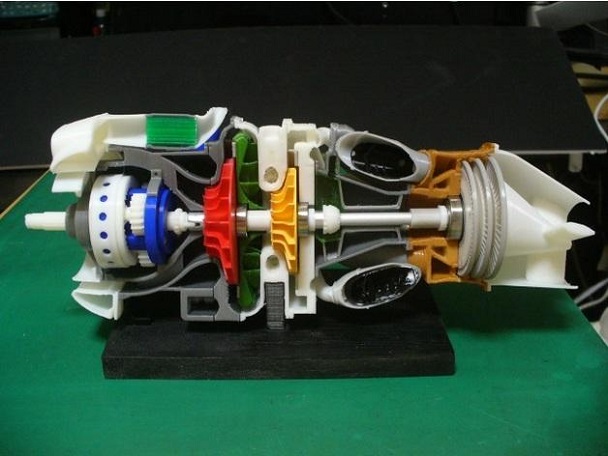

The aviation industry, known for its rigorous standards in safety, quality, and performance, is being transformed by the adoption of 3D printed aircraft parts. This innovative technology, also called additive manufacturing (AM), allows manufacturers to design, produce, and maintain aircraft components with unprecedented precision and efficiency. By constructing parts layer by layer based on digital blueprints, 3D printing is enabling the production of complex geometries and lightweight structures that were previously unimaginable using traditional manufacturing methods. The adoption of 3D printing in aviation promises not just novelty but significant gains in performance, cost-efficiency, and sustainability across the industry.

Overview of Additive Manufacturing

Additive manufacturing (AM) involves the process of building objects layer by layer from a digital model, typically in a manner that allows for greater precision and complexity than traditional methods. Unlike subtractive manufacturing, which removes material from a solid block, 3D printing deposits material precisely where it’s needed. This offers several key benefits:

- Design Flexibility: AM enables the creation of intricate shapes that were once difficult or impossible to make, allowing for optimized performance and lightweight components.

- Material Efficiency: Since material is added only where required, AM minimizes waste. This is especially advantageous when using expensive materials like titanium or carbon composites, which are commonly used in aerospace.

- Speed: AM enables faster prototyping and production, leading to reduced lead times for parts and faster responses to critical maintenance needs.

These capabilities make 3D printing particularly suited for the aviation sector, where reducing weight, enhancing performance, and optimizing production time are key priorities.

Advantages Over Traditional Manufacturing

1. Design Flexibility and Complex Geometries

One of the primary benefits of 3D printing in aviation is the ability to produce complex geometries that optimize both performance and aerodynamics. For example, lattice structures—internally complex and lightweight—can be integrated into parts like brackets, engine supports, or interior structures. These structures not only reduce weight but also improve the strength-to-weight ratio, which enhances aircraft performance. The ability to optimize designs without worrying about manufacturing constraints allows engineers to push the boundaries of innovation.

- Lattice Structures: Parts with intricate internal geometries, like honeycomb structures, provide lightweight solutions without compromising strength.

2. Weight Reduction and Fuel Efficiency

In aviation, every gram of weight matters. 3D printing allows for the design of parts that are both stronger and lighter compared to traditional methods. By utilizing advanced metal alloys and optimized designs, manufacturers can significantly reduce the weight of aircraft components, leading to lower fuel consumption and reduced carbon emissions.

- Fuel Savings: A lighter aircraft consumes less fuel, leading to long-term cost savings and more sustainable operations.

- Improved Aerodynamics: 3D printing enables the design of parts that can help reduce drag and improve overall aerodynamic performance.

3. Cost and Maintenance Benefits

The cost savings from 3D printing extend across several aspects of the aviation industry:

- Tooling and Setup Costs: Traditional manufacturing often requires expensive molds or dies. With 3D printing, tooling costs are eliminated, and there’s no need for extensive machine setups.

- On-Demand Production: Instead of maintaining large inventories of spare parts, manufacturers and airlines can 3D print parts on demand, especially for rare, obsolete, or hard-to-source components. This reduces inventory storage costs and eliminates the risk of overproduction.

- Faster Repairs: 3D printing allows for quicker repairs and modifications, reducing aircraft downtime and ensuring that planes remain operational with fewer delays.

Impact on the Aviation Industry

The introduction of 3D printed aircraft parts is reshaping the aviation industry in several key ways:

1. Operational Efficiency

For airlines and maintenance crews, the ability to rapidly produce spare parts means that aircraft can be repaired and returned to service faster. This capability is especially valuable in remote locations where access to spare parts is limited, reducing the dependency on lengthy supply chains and improving fleet turnaround times.

- Faster Turnaround: Parts can be produced locally, reducing delays associated with waiting for parts to be shipped from central warehouses.

- Global Maintenance Networks: Airlines can set up distributed 3D printing hubs in maintenance facilities worldwide to produce parts on-site, streamlining operations.

2. Sustainability

The environmental impact of aviation is a growing concern, and 3D printing offers an opportunity to make the industry more sustainable:

- Material Efficiency: By using only the amount of material needed to create a part, 3D printing reduces waste compared to traditional methods, where a significant amount of material is cut away and discarded.

- Circular Economy: The ability to produce parts on demand reduces overproduction and waste associated with traditional mass manufacturing. Parts can be recycled or repurposed, contributing to more sustainable practices.

3. Innovation and Competitive Edge

Aviation companies that adopt 3D printing gain a significant competitive advantage. The technology enables them to accelerate innovation, produce customized parts, and quickly test new prototypes. By utilizing AM for rapid prototyping, businesses can reduce time-to-market, enhance design iterations, and bring new products or features to market more quickly than competitors.

- Rapid Prototyping: Manufacturers can quickly create prototypes, allowing them to test designs and make changes before committing to mass production.

- Customization: The ability to design parts specifically for different models of aircraft allows for greater product differentiation and tailored solutions.

Challenges and Future Prospects

1. Quality Assurance and Regulatory Approval

While 3D printing offers numerous advantages, there are significant challenges that must be addressed for widespread adoption in aviation:

- Safety and Quality Assurance: 3D printed parts must meet the rigorous safety standards set by aviation authorities like the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency). Manufacturers must demonstrate that their 3D printed components can withstand the extreme conditions of flight, including temperature changes, pressure variations, and fatigue stress.

- Certification: Gaining certification for 3D printed parts is a complex process, requiring validation of materials, design, and manufacturing processes. However, as the technology matures, we can expect more streamlined certification processes.

2. Scalability and Material Development

Another challenge is the scalability of 3D printing for high-volume production. While the technology is well-suited for small-batch manufacturing and spare parts production, scaling up to full-scale production of all aircraft components remains a challenge. Additionally, the development of new materials that can withstand the demanding conditions of aviation is ongoing.

- Material Advancements: There is ongoing research into developing new metal alloys and composites that can be used in 3D printing and meet the high-strength and durability requirements of aviation components.

- Standardization: Standardizing the 3D printing process for aviation parts is crucial to ensure consistency and reliability in the final product.

3. Integration into Current Systems

Integrating 3D printed parts into existing aircraft designs and production systems requires significant changes to current practices. However, as the technology matures and becomes more cost-effective, it is expected that the industry will embrace additive manufacturing as a core part of its operations.

Regulatory Approvals and Safety Concerns

The approval of 3D printed aircraft parts is a critical step in ensuring their safety and performance. The FAA and EASA are developing frameworks and guidelines to allow for the safe integration of 3D printed components into commercial aircraft. These agencies require extensive testing to ensure that parts meet safety standards and can withstand the stressors of flight.

- Certification: Manufacturers must demonstrate that 3D printed parts can meet rigorous performance standards, undergo extensive testing, and gain approval for use in commercial aircraft.

- Ongoing Research: Regulatory bodies are also working with manufacturers to ensure the safe and efficient integration of additive manufacturing into aviation operations.

Potential for Widespread Adoption in Aviation

The potential for widespread adoption of 3D printing in aviation is vast. As the technology improves and becomes more accepted within the industry, we can expect it to be used not just for custom components and spare parts, but for full-scale production of entire aircraft components. The combination of faster production, design flexibility, and cost savings could fundamentally alter how aircraft are designed, produced, and maintained.

- Commercial Aircraft: 3D printing is expected to be adopted for both civilian and military aircraft, enabling lower costs, greater customization, and more efficient operations.

- Military Aviation: In military aviation, 3D printing can reduce logistical challenges, allowing for on-site production of parts and equipment.

FAQ

Q1: Are 3D printed aircraft parts as strong as traditionally manufactured parts?

A1: Yes, 3D printed parts can be as strong, if not stronger, than traditionally manufactured parts. Using high-performance materials like titanium, stainless steel, and specialized polymers, 3D printed components meet the stringent strength requirements of the aviation industry. Moreover, optimized design features, such as lattice structures, can enhance the strength-to-weight ratio.

Q2: How long does it take to produce a 3D printed aircraft part compared to a traditionally manufactured part?

A2: The production time for a 3D printed aircraft part is often much faster than traditional manufacturing methods. For instance, simple components can be printed in a few hours, while more complex parts may take several days. Traditional methods like casting or machining may take weeks, making 3D printing a much quicker solution for prototyping and spare part production.

Q3: What are some common materials used in 3D printing for aircraft parts?

A3: Common materials used for 3D printed aircraft parts include metals like titanium, aluminum, and stainless steel, as well as high-performance polymers like PEEK (Polyether Ether Ketone) and Ultem. These materials are chosen for their strength, heat resistance, and lightweight properties, making them ideal for use in aircraft components.

Conclusion

3D printed aircraft parts are driving a revolution in the aviation industry by enabling lighter, more efficient, and cost-effective production methods. As technology matures and regulatory hurdles are addressed, we can expect broader adoption across various sectors of aviation, including commercial, military, and private aviation. By embracing additive manufacturing, the industry stands to achieve new levels of performance, sustainability, and innovation.