Applications of 3D Print Service in London

In the Manufacturing Industry

In the manufacturing industry, 3D print service in London has become an indispensable tool. For rapid prototyping, it allows companies to quickly transform their design concepts into physical models. For example, a local product design startup in London saved about 40% of the time in the prototype development phase by using 3D printing compared to traditional manufacturing methods. This enabled them to bring their innovative products to market much faster, gaining a competitive edge.

When it comes to custom manufacturing, 3D printing can produce complex and customized parts that are difficult to manufacture with traditional methods. A manufacturing company in London once received an order for a set of parts with intricate internal structures for a high - end equipment. With 3D printing technology, they successfully completed the production, which not only met the special requirements of the customer but also reduced the production cost by about 30% compared to outsourcing the parts to overseas manufacturers.

In the Medical Field

The application of 3D print service in the medical field in London has brought revolutionary changes. In the aspect of custom - made prosthetics, doctors can create prosthetics that fit patients' bodies perfectly according to their specific physical conditions. A study showed that 95% of patients who used 3D - printed prosthetics reported better comfort and functionality compared to traditional prosthetics.

In the production of medical devices, 3D printing also plays an important role. For instance, some hospitals in London use 3D - printed surgical guides, which can improve the accuracy of surgeries. In a complex orthopedic surgery, with the help of 3D - printed surgical guides, the operation time was reduced by about 20%, and the success rate of the surgery increased by 15%. Additionally, 3D - printed anatomical models are widely used for medical education and preoperative planning, helping medical students better understand human anatomy and surgeons better plan surgical procedures.

In the Art and Design Sphere

3D print service has opened up new creative possibilities for the art and design world in London. Artists can use 3D printing to create unique artworks with complex shapes and structures that were previously difficult to achieve. London - based artist Jane Smith created a series of 3D - printed sculptures that combined traditional art elements with modern digital technology. These artworks attracted a lot of attention in the art exhibitions and were highly praised for their innovation.

Designers also benefit a lot from 3D printing. Fashion designers can create customized clothing with unique textures and shapes. A local fashion brand in London launched a 3D - printed clothing collection, which was well - received in the fashion market for its avant - garde design. Graphic designers can use 3D printing to turn their flat designs into three - dimensional objects, adding a new dimension to their works.

How to Choose a 3D Print Service Provider in London

Consider the Equipment and Technology

When choosing a 3D print service provider in London, the equipment and technology they use are crucial factors. Different 3D printing technologies have their own characteristics and application scenarios. For example, FDM (Fused Deposition Modeling) is a widely used technology. It works by heating and extruding thermoplastic filaments layer by layer to form objects. It has the advantages of relatively low cost, a wide range of available materials such as PLA, ABS, and PETG, and is suitable for creating large - scale prototypes and functional parts with simple structures. A startup in London that develops simple mechanical prototypes may choose an FDM - based 3D print service because they can quickly produce prototypes at a lower cost to test their design concepts.

On the other hand, SLA (Stereolithography) uses a laser to cure liquid photopolymer resin layer by layer. It offers high - precision printing, capable of creating fine details and smooth surfaces. This makes it ideal for applications like jewelry design, dental models, and intricate artworks. A London - based jewelry designer would prefer an SLA 3D print service to bring their detailed and delicate jewelry designs to life. Another technology, SLS (Selective Laser Sintering), sinters powdered materials such as nylon to form solid objects. It is suitable for producing parts with complex internal structures and high - strength requirements, often used in the automotive and aerospace industries.

Evaluate the Material Options

The material options provided by a 3D print service in London are also very important. Common materials used in 3D printing in London include:

- PLA (Polylactic Acid): Made from renewable resources like corn starch or sugarcane. It is easy to print, has a low melting point, and produces minimal odor during printing. It is often used for creating decorative items, educational models, and simple prototypes due to its good printability and environmental - friendliness.

- ABS (Acrylonitrile Butadiene Styrene): A strong and heat - resistant thermoplastic. It has high impact resistance and is suitable for making mechanical parts, functional prototypes, and durable products. However, it requires a heated printing bed as it has a relatively high shrinkage rate, which can cause warping during cooling.

- Resin: Used in SLA and DLP (Digital Light Processing) 3D printing. Resin can achieve high - resolution and detailed prints. There are different types of resins, such as general - purpose resin for normal models, flexible resin for creating elastic parts, and high - temperature - resistant resin for applications that need to withstand heat.

Yigu Technology's View

Yigu Technology, as a non - standard plastic metal products custom Supplier, closely follows the global trend of 3D printing technology. Currently, 3D printing is witnessing a remarkable development worldwide. It has been gradually integrated into various industries, bringing about significant changes in production methods.

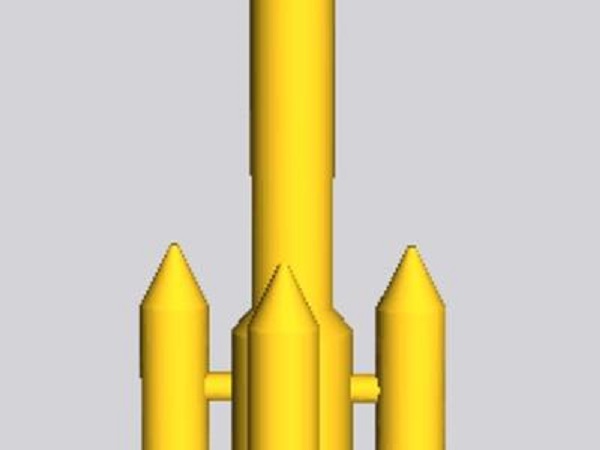

One of the most prominent advantages of 3D printing is its ability to realize the forming of parts with complex structures, which is a major bottleneck for traditional manufacturing methods. This not only enriches the design space for engineers but also enables the production of high - performance products that were previously unattainable. Additionally, 3D printing can effectively reduce production costs and shorten the production cycle, especially in small - batch production and customization scenarios. For example, in the production of non - standard plastic metal products, 3D printing can quickly produce samples and small - batch products according to customer requirements, avoiding the high cost of traditional mold - making.

In the future, 3D printing technology is expected to have even greater potential in various fields. In the manufacturing industry, it will further promote the transformation towards intelligent and customized manufacturing. In the medical field, it may play a more crucial role in personalized treatment and organ transplantation. Yigu Technology believes that by continuously exploring and applying 3D printing technology, it can better meet the diverse needs of customers and contribute to the development of the industry.

FAQ

What types of materials can be used for 3D printing in London?

In London, a wide variety of materials can be used for 3D printing. PLA (Polylactic Acid) is a popular choice. It is made from renewable resources like corn starch or sugarcane, making it environmentally friendly. PLA has a relatively low melting point, which makes it easy to print with, and it produces minimal odor during the printing process. It is often used for creating decorative items, educational models, and simple prototypes. For example, schools in London may use PLA to print 3D models for science classes.

ABS (Acrylonitrile Butadiene Styrene) is another common material. It is a strong and heat - resistant thermoplastic. ABS has high impact resistance, which makes it suitable for making mechanical parts, functional prototypes, and durable products. However, it requires a heated printing bed due to its relatively high shrinkage rate. For instance, a local engineering firm in London might use ABS to print parts for small - scale mechanical devices.

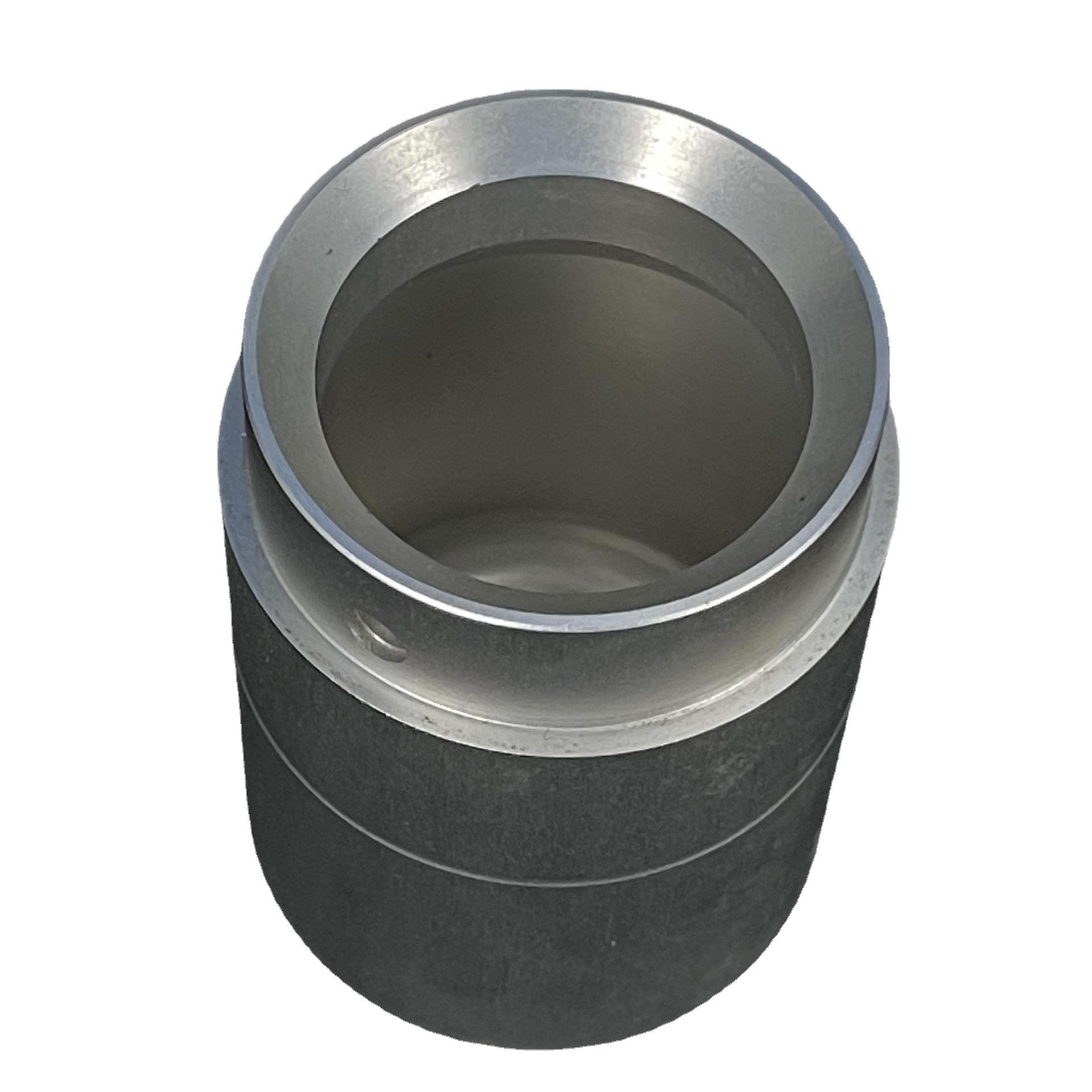

Metal powders such as aluminum, titanium, and stainless steel are also used in 3D printing, especially in industrial and high - tech applications. Aluminum powder is lightweight and has good thermal conductivity, so it is used in the aerospace and automotive industries. Titanium powder is known for its high strength - to - weight ratio and excellent corrosion resistance, making it ideal for medical implants and aerospace components. Stainless steel powder is used for creating parts that require high strength and corrosion resistance, like in the food and chemical industries.

How long does it usually take to complete a 3D printing project in London?

The time it takes to complete a 3D printing project in London depends on several factors. The complexity of the model is a major factor. A simple, small - scale model with a basic geometric shape may take only a few hours to print. For example, a small 3D - printed keychain in a simple shape could be completed in 2 - 3 hours on a standard desktop 3D printer.

The size of the model also matters. Larger models will naturally take longer to print as more material needs to be deposited layer by layer. A large - scale architectural model that is several feet in size might take days to complete.

The number of printers available for the job also affects the delivery time. If a 3D print service in London has multiple high - speed printers running simultaneously, they can complete projects more quickly. In general, for a moderately complex and average - sized object, it could take anywhere from 12 hours to 2 days. However, for very large or highly intricate projects, the time could extend to a week or more.