What is Fused Deposition Modeling?

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is a popular 3D printing technology that falls under the category of material extrusion in additive manufacturing. It is widely used for creating three - dimensional objects by building them layer by layer. As one of the most common 3D printing methods, FDM has found applications in various fields, from prototyping in product design to creating custom - made parts in small - scale manufacturing. Understanding how FDM works is crucial for anyone looking to utilize this technology effectively, whether you are a hobbyist, a designer, or a manufacturer.

The Working Principle of Fused Deposition Modeling

Material Preparation

FDM commonly uses thermoplastic filaments as materials, such as ABS (Acrylonitrile Butadiene Styrene), PLA (Polylactic Acid), PETG (Polyethylene Terephthalate Glycol), and more. For instance, ABS is known for its strength and heat - resistance, making it suitable for applications that require durability. PLA, on the other hand, is a popular choice due to its environmental - friendliness and ease of printing.

The process begins with loading the filament into the 3D printer. The filament is typically wound on a spool and fed into the printer's extruder mechanism. Once inside, the material is guided towards the print head. The print head contains a heating element, which raises the temperature of the filament to its melting point. For ABS, this temperature is usually around 220 - 250°C, while for PLA, it is in the range of 180 - 220°C. As the filament melts, it becomes a semi - liquid state, ready to be extruded for the printing process.

The Printing Process

Once the material is melted, the printing process commences. The print head, which is connected to a three - axis (X, Y, Z) motion system, is controlled by a computer. The computer reads the G - code, which is generated from a 3D model that has been sliced into thin layers.

The print head moves in the X and Y directions across the build platform, extruding the melted material in a precise pattern. For example, if you are printing a cube, the print head will first create the perimeter of the bottom layer of the cube, extruding the material in a square shape. Then, it will fill in the interior of the square with a specific infill pattern, such as a honeycomb or grid. The extrusion rate is carefully controlled to ensure that the right amount of material is deposited. A typical extrusion rate might be in the range of 5 - 50 mm³/s, depending on the printer and the material being used.

Layer - by - Layer Stacking

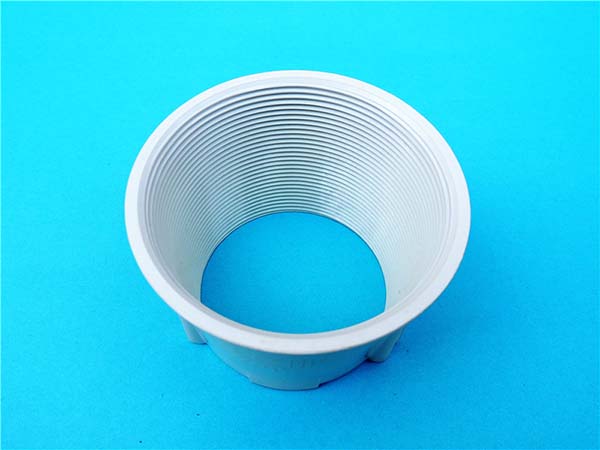

After the first layer is complete, the build platform either lowers (in most common FDM printers) or the print head raises (in some models) by a distance equal to the thickness of a single layer. This layer thickness can vary, but common values are between 0.1 mm and 0.4 mm. For high - resolution prints, a thinner layer thickness like 0.1 mm is chosen, which results in a smoother surface finish but longer print times. For less detailed prints or larger objects, a thicker layer thickness such as 0.3 mm or 0.4 mm can be used to speed up the printing process.

The print head then begins depositing the next layer of material on top of the previously printed layer. The newly deposited material bonds with the underlying layer due to the heat and the adhesive properties of the thermoplastic. This process continues layer by layer until the entire 3D object is fully formed. As an example, a small figurine that is 10 cm tall and has a layer thickness of 0.2 mm would require 50 layers to be printed.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the role of Fused Deposition Modeling (FDM) in the field of custom product manufacturing.

One of the significant advantages of FDM in custom product applications is its flexibility. It allows for the creation of highly customized parts with complex geometries. For example, when manufacturing small - batch, customized plastic components, FDM can quickly turn design ideas into physical products, reducing the lead - time compared to traditional manufacturing methods. This is crucial for industries that require rapid prototyping and short - cycle production.

However, FDM also faces some challenges. The relatively low resolution compared to some other 3D printing technologies can be a drawback when high - precision parts are needed. Additionally, the limited material selection in some FDM printers may restrict its application in certain high - performance product manufacturing scenarios.

Despite these challenges, the future potential of FDM is promising. With the continuous development of materials science and 3D printing technology, we expect to see more advanced filaments with improved mechanical properties and heat - resistance. This will expand the scope of FDM in manufacturing more functional and durable non - standard products. Yigu Technology will continue to explore and apply FDM technology to better serve our customers' custom - manufacturing needs.

FAQ

What materials can be used in FDM 3D printing?

Common materials for FDM 3D printing include ABS, PLA, PETG, TPU (Thermoplastic Polyurethane), and Nylon. ABS offers high strength and heat - resistance, suitable for functional prototypes and parts that need to withstand stress. PLA is biodegradable, easy to print, and has a relatively low melting point, making it a great choice for beginners and environmentally - conscious projects. PETG has good chemical resistance and transparency, often used for creating clear enclosures or parts that require chemical stability. TPU is flexible, ideal for items like phone cases or flexible hinges. Nylon has high strength and abrasion resistance, suitable for parts that need to endure wear and tear, such as gears.

How to improve the surface quality of FDM printed parts?

To enhance the surface quality, start by optimizing print parameters. Reduce the layer height; a thinner layer (e.g., 0.1mm instead of 0.2mm) results in a smoother surface. Adjust the extrusion temperature to ensure the material flows evenly. A slightly higher temperature for some materials can improve adhesion between layers and reduce visible layer lines.

Post - processing also plays a crucial role. Sanding the printed part can smooth out rough surfaces. Start with a coarse grit sandpaper to remove large imperfections and then gradually move to finer grits for a polished finish. Another option is chemical vapor smoothing, especially for ABS parts. Acetone vapor can be used to dissolve the surface layer slightly, creating a smooth and glossy finish.

What are the common problems in FDM printing and how to solve them?

One common issue is nozzle clogging. This can be caused by debris in the filament or inconsistent filament diameter. To solve it, first, try heating the nozzle and manually pushing the filament through. If that doesn't work, disassemble the nozzle and clean it thoroughly. Using a nozzle cleaning kit can be very helpful.

Another problem is uneven material extrusion. This might be due to a faulty extruder gear or a problem with the filament feeding mechanism. Check the extruder gear for signs of wear and ensure the filament is being fed smoothly. Adjust the tension of the filament feeder if necessary.

Layer delamination can also occur, often because of poor adhesion between layers. To fix this, increase the bed temperature to improve adhesion, or use a bed adhesive like glue stick or hairspray to help the first layer stick better to the build platform.