What are Custom 3D Printed Parts?

Custom 3D printed parts are components created to meet specific requirements, distinct from mass - produced, standardized items. They are brought to life through 3D printing technology, also known as additive manufacturing.

The process begins with a digital model, often designed using computer - aided design (CAD) software. This digital file serves as the blueprint for the 3D printer. The printer then builds the part layer by layer, starting from the bottom and gradually adding material until the entire three - dimensional object is formed. The materials used can vary widely, including plastics like PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene), metals such as titanium and aluminum, and even ceramics and composites in some advanced applications. For example, in the aerospace industry, custom 3D printed titanium parts are used due to their high strength - to - weight ratio. These parts can be designed to have complex internal geometries that would be nearly impossible to achieve with traditional manufacturing methods, such as casting or machining.

Different Materials for Custom 3D Printed Parts

Plastics

Plastics are among the most commonly used materials in 3D printing. Here are some of the popular ones:

| Plastic Material | Properties | Typical Applications |

| PLA (Polylactic Acid) | Biodegradable, easy to print, low warping, relatively low strength. It has a smooth surface finish and comes in a variety of colors. | Ideal for consumer products like phone cases, toys, and simple prototypes. For example, a small - scale designer might use PLA to create unique, custom - designed jewelry pieces. |

| ABS (Acrylonitrile Butadiene Styrene) | Stronger and more heat - resistant than PLA, but more difficult to print as it has a tendency to warp. It is rigid and has good impact resistance. | Used in applications where strength is important, such as automotive parts prototypes, like interior trim components, and in the creation of functional prototypes for electronic enclosures. |

| PETG (Polyethylene Terephthalate Glycol - modified) | Combines the strength of ABS with the ease - of - printing of PLA. It has high chemical resistance, transparency, and is shatter - resistant. | Suited for applications that require both strength and transparency, such as food containers, water bottles, and display cases. |

Metals

Metal 3D printing has opened up new possibilities in various industries.

- Titanium Alloy: Titanium alloys offer an excellent strength - to - weight ratio. They are highly corrosion - resistant, which makes them ideal for aerospace applications. For instance, in the construction of aircraft engines, custom 3D printed titanium alloy parts can reduce the weight of the engine components while maintaining high strength, thus improving fuel efficiency.

- Aluminum Alloy: Aluminum alloys are lightweight and have good thermal conductivity. They are widely used in the automotive industry for manufacturing engine parts, like cylinder heads. The 3D printing process allows for the creation of complex internal cooling channels, which can enhance the engine's performance.

Other Materials

- Ceramics: Ceramic 3D printing is used for applications that require high - temperature resistance and chemical stability. For example, in the production of heat - resistant furnace linings or high - precision dental crowns. The 3D printing process enables the creation of intricate shapes that are difficult to achieve with traditional ceramic manufacturing methods.

- Composites: Composites, which are combinations of different materials, are also being explored in 3D printing. For example, carbon fiber - reinforced composites can be 3D printed to create parts with high strength and stiffness. These are used in high - performance applications such as in the production of sports equipment, like bicycle frames, where the combination of light weight and high strength is crucial.

The Process of Creating Custom 3D Printed Parts

Creating custom 3D printed parts is a multi - step process that requires precision and attention to detail at every stage.

Designing the Model

The design phase is the foundation of creating custom 3D printed parts. Designers typically use computer - aided design (CAD) software. This software allows for the creation of highly detailed 3D models. For example, in the development of a custom - designed prosthetic limb, CAD software enables the designers to precisely map out the shape, taking into account the patient's specific limb measurements, range of motion requirements, and aesthetic preferences. The software also allows for the easy modification of the design. If a particular feature needs adjustment, it can be done with just a few clicks, saving a significant amount of time compared to traditional design methods. Designers can also perform simulations within the CAD environment to test the functionality of the part before moving to the printing stage.

Pre - processing

Once the design is complete, the model needs to be prepared for printing through pre - processing steps. One of the crucial pre - processing steps is slicing. Slicing software takes the 3D model and divides it into hundreds or even thousands of thin layers. The thickness of these layers, known as the layer height, is a critical parameter. A smaller layer height, such as 0.1mm, will result in a smoother surface finish but will also increase the printing time. On the other hand, a larger layer height, like 0.3mm, can speed up the printing process but may lead to a more noticeable layer - by - layer appearance on the final part. Other pre - processing tasks may include adding support structures. For parts with overhangs or complex geometries, support structures are necessary to prevent the part from collapsing during printing. These supports are typically made of the same or a similar material as the part itself and can be removed after printing.

Printing

There are several 3D printing technologies available, each with its own set of advantages and suitable applications.

- Fused Deposition Modeling (FDM): This is one of the most common 3D printing technologies. It works by heating a plastic filament until it becomes molten. The molten plastic is then extruded through a nozzle and deposited layer by layer to build the part. FDM is popular because it is relatively low - cost, and the equipment is easy to operate. It is often used for creating prototypes, such as a simple prototype of a new smartphone case. However, the surface finish of FDM - printed parts is usually not as smooth as those printed with other technologies.

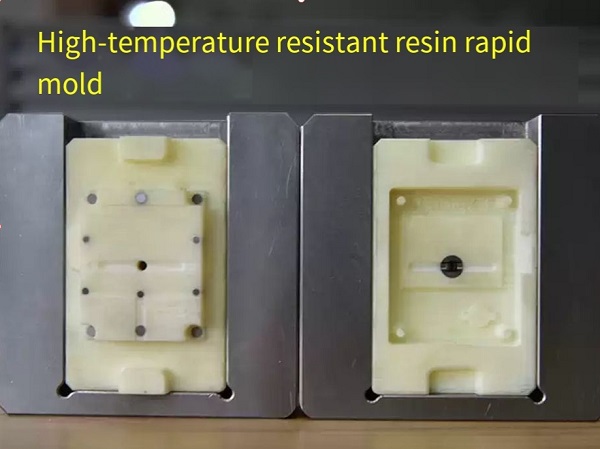

- Stereolithography (SLA): SLA uses a laser to cure a liquid resin, layer by layer, to form the 3D object. This technology can achieve very high precision, with layer thicknesses as small as 0.05mm. SLA is ideal for applications that require high - detail parts, such as jewelry casting models or dental crown prototypes. The surface finish of SLA - printed parts is smooth, making it suitable for parts where aesthetics matter.

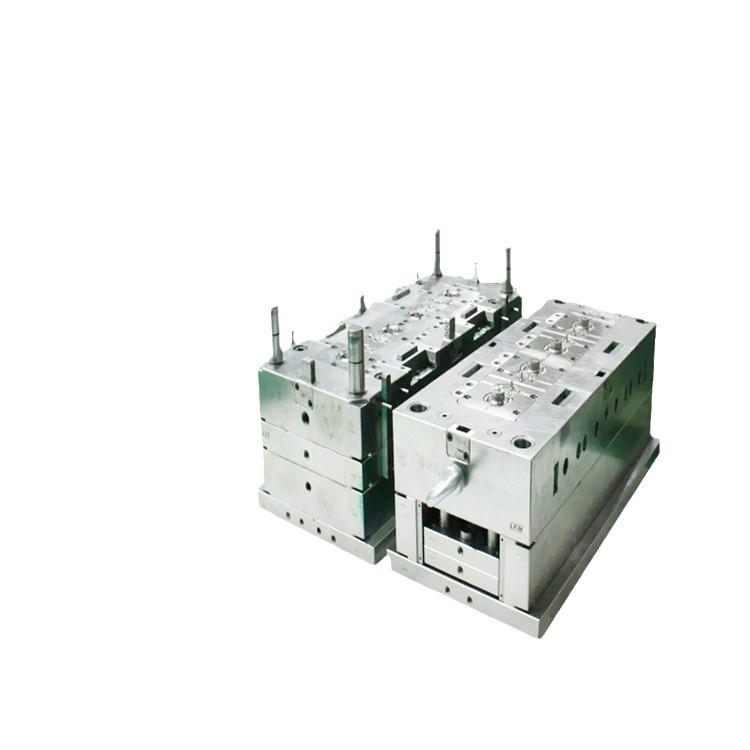

- Selective Laser Sintering (SLS): SLS uses a laser to sinter powdered materials, such as plastic or metal powders. The laser fuses the powder particles together in the shape of each layer, gradually building up the part. SLS is known for its ability to produce strong and durable parts without the need for support structures, as the unsintered powder supports the part during the printing process. It is often used in the production of functional parts in industries like automotive and aerospace.

Post - processing

After the printing is complete, post - processing is often required to achieve the desired final product. One common post - processing step is sanding. Sanding helps to smooth out the surface of the part, removing any rough edges or layer lines. For parts that require a high - quality finish, multiple sanding steps may be involved, starting with a coarse - grit sandpaper to remove larger imperfections and gradually moving to finer - grit sandpapers for a smoother finish. Painting is another post - processing option. It can enhance the appearance of the part and also provide additional protection. For example, a 3D printed plastic part that will be used outdoors may be painted with a weather - resistant paint to prevent degradation. Other post - processing techniques may include polishing, which gives the part a shiny, mirror - like finish, and heat - treating for metal parts to improve their mechanical properties.

Yigu Technology's Viewpoint

Yigu Technology firmly believes that custom 3D printed parts are revolutionizing the non - standard plastic and metal products sector. These parts can meet the diverse and unique needs of different industries, from the complex requirements of aerospace to the personalized demands of consumer products.

With a professional team of engineers and state - of - the - art equipment, Yigu Technology is well - equipped to handle custom 3D printing projects. We understand the nuances of different materials and printing processes, ensuring that each custom part we produce meets the highest quality standards. Whether it's a one - off prototype or a small - batch production, we can provide efficient and high - quality services, helping clients turn their ideas into tangible products.

FAQ

What is the lead time for custom 3D printed parts?

The lead time for custom 3D printed parts can vary significantly. Generally, it ranges from a few days to several weeks. For simple parts with a small quantity, it might only take 3 - 5 days. For example, if you order a small batch of simple plastic prototypes, they could be ready within a week. However, for complex parts with intricate geometries or large - scale production runs, it could take up to 4 - 6 weeks. Factors such as the complexity of the design, the type of material used, and the availability of the 3D printing equipment all contribute to the lead time.

Can I get a sample before mass production?

Yes, most 3D printing service providers, including Yigu Technology, offer the option to produce a sample before mass production. This is a crucial step as it allows you to verify the design, dimensions, and overall quality of the part. Once you are satisfied with the sample, the production of the full batch can commence. This helps to avoid costly mistakes and ensures that the final products meet your expectations.

What if there are defects in the custom 3D printed parts?

If there are defects in the custom 3D printed parts, the first step is for the supplier to conduct a thorough analysis to determine the root cause. This could be due to issues with the design, the printing process, or the material. Once the cause is identified, the supplier, like Yigu Technology, will typically offer to re - print the parts at no additional cost. In some cases, if re - printing is not feasible, they will work with you to find an alternative solution, such as providing a discount on the order or offering a replacement part of a different design that still meets your requirements.