Introduction

In the landscape of modern manufacturing, innovation and efficiency are the keys to success. Among the numerous technological advancements, SLS printing has emerged as a revolutionary technology, playing a crucial role in various industries. But what exactly is SLS printing? If you've been puzzled by the term “sls printing meaning” and are eager to understand its ins and outs, you've come to the right place. This article will explore the meaning, working principle, applications, and advantages of SLS printing, aiming to provide you with a comprehensive understanding of this remarkable technology.

Definition of SLS Printing

1. Technical Explanation

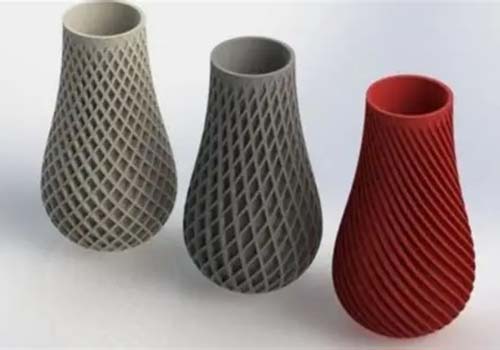

SLS printing, short for Selective Laser Sintering, is an advanced additive manufacturing technology. Its core principle lies in the utilization of a high - energy laser beam to selectively sinter powdered materials layer by layer to create three - dimensional objects.

Here's a more in - depth look at the process. First, a thin layer of powder material, which can be a variety of substances such as plastics (like nylon), metals, or ceramics, is evenly spread across a powder bed. The powder is pre - heated to a temperature slightly below its melting point. Then, a computer - controlled laser scans the cross - sectional pattern of the object to be fabricated onto the powder layer. As the laser beam hits the powder, the heat causes the powder particles to fuse together, forming a solid layer that corresponds to the shape of the cross - section. Once one layer is completed, the powder bed is lowered by a certain thickness (usually in the range of 0.08 - 0.3mm), a new layer of powder is spread, and the laser - sintering process is repeated. This iterative process continues until the entire three - dimensional object is built.

2. Key Components Involved

- Laser Source: This is the heart of the SLS printing system. High - power lasers, such as CO₂ lasers or fiber lasers, are commonly used. The laser must be able to emit a focused and intense beam to provide sufficient energy for sintering the powder materials. For example, a CO₂ laser can generate a laser beam with a wavelength of around 10.6 micrometers, which is highly absorbed by many powder materials, facilitating the sintering process.

- Powder Bed: It serves as the platform on which the powder is placed and the object is built. The powder bed needs to have precise movement control in the vertical direction to ensure accurate layer - by - layer deposition. It is usually made of materials that can withstand the heat generated during the sintering process without deforming.

- Scanning System: Comprising galvanometer - based mirrors or other scanning mechanisms, the scanning system is responsible for directing the laser beam accurately across the powder bed according to the digital model's cross - sectional data. It can quickly and precisely move the laser beam to cover the entire area of each layer, with high - speed scanning speeds reaching up to several meters per second in some advanced SLS printers.

- Powder Delivery and Recoating System: This system is in charge of evenly spreading a new layer of powder over the previously sintered layer. It typically includes a powder hopper to store the powder and a recoating blade or roller that moves across the powder bed to ensure a uniform powder thickness for each layer.

Working Process of SLS Printing

1. Step - by - Step Illustration

- Powder Preparation and Spreading:

- First, the chosen powder material is carefully prepared. This may involve processes such as sieving to ensure uniform particle size distribution. For example, if using nylon powder for SLS printing, it needs to be sieved to remove any large agglomerates that could affect the sintering process.

- A layer of the powder, typically around 0.08 - 0.3mm thick, is evenly spread across the powder bed. A recoating mechanism, such as a roller or a blade, is used to achieve this uniform spreading. This layer serves as the base for the first cross - section of the object to be built.

- Laser Sintering:

- Once the powder layer is in place, a high - energy laser beam, controlled by a computer - aided design (CAD) model of the object, scans the surface of the powder. The laser beam follows the cross - sectional pattern of the object at that particular layer. As the laser hits the powder, it raises the temperature of the powder particles to their melting or sintering point. For instance, in metal SLS printing, the laser energy causes the metal powder particles to fuse together through a sintering process, forming a solid layer that corresponds to the shape defined by the CAD model's cross - section at that height.

- Layer - by - Layer Building:

- After the first layer is sintered, the powder bed is lowered by the thickness of one layer. A new layer of powder is then spread over the previously sintered layer. The laser sintering process is repeated for this new layer, bonding it to the underlying layer. This iterative process continues layer by layer. Each layer is a two - dimensional cross - section of the three - dimensional object, and as more layers are added, the object gradually takes shape.

- Cooling and Finishing:

- Once the entire object has been built layer by layer, the printed part needs to cool down. This cooling process is crucial as it allows the sintered material to solidify properly and maintain its shape. After cooling, the part may require some post - processing steps. These can include removing any excess powder that is still adhered to the part, sanding to improve surface finish, and in some cases, heat - treating to enhance the mechanical properties of the printed object. For example, metal SLS - printed parts may be heat - treated to relieve internal stresses and improve hardness.

Comparison with Other Printing Methods

1. Tabular Comparison with FDM (Fused Deposition Modeling)

FDM (Fused Deposition Modeling) is another popular 3D printing technology. Here is a comparison between SLS printing and FDM from multiple aspects:

| Comparison Items | SLS Printing | FDM |

| Cost | - Equipment cost is relatively high, but in the long run, for large - scale production, the cost per unit can be reduced due to high - efficiency production and less post - processing requirements. - Material cost depends on the powder material, but overall, it can be cost - effective for certain materials. | - Equipment cost is generally lower, especially for entry - level desktop FDM printers. - Material cost for filaments like PLA and ABS is relatively affordable, but some high - performance filaments can be costly. However, material waste is relatively high as the support structures often need to be made of the same material as the model. |

| Precision | High precision, with layer thicknesses typically ranging from 0.08 - 0.3mm. It can achieve fine details, suitable for complex geometric models. | Generally lower precision compared to SLS. Layer thickness is often in the range of 0.1 - 0.4mm, which may result in visible layer lines and less accurate reproduction of fine features, especially for small - scale or complex designs. |

| Material Selection | Wide range of materials, including various plastics (such as nylon, polypropylene), metals (e.g., titanium, aluminum alloy powders), and ceramics. Different materials can meet diverse application requirements, like high - strength metal parts for aerospace or biocompatible materials for medical use. | Mainly limited to thermoplastic materials such as PLA, ABS, PETG, TPU, etc. Although the variety of available filaments is growing, it still has a narrower range compared to SLS in terms of material types. |

| Prototyping Speed | Faster in building complex structures as it doesn't require support structures in most cases. The powder bed can be quickly recoated, and the laser can sinter multiple areas simultaneously in some advanced SLS systems. | Slower for complex models because the extrusion head needs to move along the contour to deposit materials layer by layer, and support structures need to be printed as well, which adds to the printing time. |

2. Comparison with SLA (Stereolithography Apparatus)

SLA (Stereolithography Apparatus) is a 3D printing technology that uses a laser to cure liquid resin layer by layer. Here is a comparison in a list form:

- Material State:

- SLS Printing: Utilizes powdered materials. This allows for a wide range of materials to be used, including some that are difficult to process in a liquid state like certain high - temperature - resistant plastics and metals.

- SLA: Works with liquid 光敏树脂. The resin needs to have specific light - curing properties, and the range of available resins is more limited compared to SLS powder materials.

- Precision and Surface Finish:

- SLS Printing: Offers high precision, especially suitable for complex internal structures. However, the surface finish may be slightly rougher compared to SLA in some cases, although post - processing can improve it significantly.

- SLA: Generally provides an extremely smooth surface finish, making it ideal for applications where aesthetics are crucial, such as jewelry design and dental models. It can achieve very high precision, with layer thicknesses as low as 0.025mm in some high - end SLA printers.

- Strength of Printed Parts:

- SLS Printing: Produces parts with relatively high strength, especially when using materials like metal powders. The sintering process can create a dense and strong structure, suitable for functional parts in industries like automotive and aerospace.

- SLA: Printed parts made from resin are usually more brittle. Although there are high - strength resins available, the overall strength of SLA - printed parts is generally lower than SLS - printed parts in applications that require high mechanical stress resistance.

- Application Scenarios:

- SLS Printing: Is suitable for manufacturing functional prototypes, end - use parts in industries with high - performance requirements (e.g., automotive, aerospace, and industrial machinery), and parts with complex internal geometries where support structures are difficult to implement.

- SLA: Is mainly used in fields where high - precision and smooth surface finishes are required, such as jewelry making, dental applications (creating dental crowns and bridges), and the production of small, detailed models for product design visualization.

Conclusion

In summary, SLS printing, or Selective Laser Sintering, is a remarkable 3D printing technology that uses a laser to sinter powdered materials layer by layer to create 3D objects. It offers several advantages, such as high design freedom, no need for support structures in most cases, a wide range of available materials, and relatively high - strength printed parts. These advantages have led to its widespread application in industries like automotive, aerospace, medical, and consumer goods.

However, SLS printing also faces some challenges, including high initial equipment costs, limited material availability compared to traditional manufacturing, and the need for post - processing in some cases to improve surface finish. Despite these challenges, with the continuous development of technology and the expansion of material research, SLS printing has great potential for growth. It is expected to play an even more significant role in modern manufacturing, driving innovation and enabling the production of more complex and high - performance products. As the technology matures, it may also become more accessible and cost - effective, further expanding its application scope across various industries.

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom Supplier, Yigu Technology has witnessed the profound impact of SLS printing on product manufacturing. SLS printing enables the production of products with complex structures that were previously difficult to achieve through traditional manufacturing methods. For example, in the production of some plastic components with intricate internal channels and hollow structures, SLS printing can directly create these complex geometries without the need for multiple assembly processes, thus improving product performance and reducing production costs.

In terms of material utilization, SLS printing shows great advantages. The un - sintered powder can be recycled, which not only reduces material waste but also lowers production costs. This is especially beneficial for high - cost metal powders. Yigu Technology has applied SLS technology to produce some small - batch metal parts. The production efficiency has been significantly improved compared with traditional machining methods. It can quickly respond to customer needs and shorten the product development cycle. Moreover, the mechanical properties of the parts produced by SLS printing can meet the requirements of most applications, which makes it an ideal choice for custom - made non - standard products.

FAQ

1. What materials can be used in SLS printing?

Common materials used in SLS printing include nylon, which is popular for its strength, flexibility, and chemical resistance; metal powders like titanium, aluminum alloy, and stainless steel, suitable for high - strength applications in aerospace and automotive industries; ceramic powders for applications requiring high - temperature resistance and wear resistance; and some composite powders. The choice of material significantly impacts product performance. For example, nylon - based materials are great for functional prototypes and end - use parts in consumer goods due to their good mechanical properties and relatively low cost. Metal powders, on the other hand, can produce parts with high strength and heat resistance, making them ideal for engine components in the automotive and aerospace sectors.

2. How accurate is SLS printing?

The accuracy of SLS printing typically has a tolerance range of ±0.1 - 0.2mm. However, this can be affected by multiple factors. The precision of the SLS equipment itself plays a crucial role. High - end SLS printers with advanced laser scanning systems and precise powder bed movement control can achieve better accuracy. Material characteristics also matter. For instance, the particle size and distribution of the powder can influence the smoothness and accuracy of the sintered layers. Smaller and more uniform powder particles generally result in higher - precision prints. Additionally, process parameters such as laser power, scanning speed, and layer thickness setting can all impact the final accuracy. A well - optimized combination of these parameters is necessary to obtain the best - possible accuracy.

3. Is SLS printing suitable for mass production?

SLS printing has both advantages and limitations for mass production. In terms of cost, although the initial investment in SLS equipment is high, for complex parts with high - value materials, the cost per unit can be reduced in large - scale production due to high material utilization and less need for post - processing compared to some traditional manufacturing methods. Regarding efficiency, SLS can build multiple parts simultaneously in the powder bed, which is beneficial for medium - to - high - volume production. It also doesn't require the time - consuming setup of molds or fixtures like traditional manufacturing. However, SLS printing may face challenges in mass production, such as relatively slow printing speed compared to high - volume injection molding for simple parts, and the need for careful quality control to ensure consistent part quality across large production runs, as factors like powder aging and equipment wear can affect the quality of printed parts over time.