Introduction

In the dynamic realm of aviation, the advent of 3D printed airplane parts has emerged as a game - changing innovation. As the demand for more efficient, cost - effective, and customizable aircraft components continues to grow, 3D printing technology, also known as additive manufacturing, has stepped into the spotlight. But what exactly are the implications of this technology? How does it revolutionize the traditional manufacturing processes in the aviation industry? And what challenges and opportunities lie ahead?

This article will explore the world of 3D printed airplane parts, delving into their numerous advantages, the hurdles that must be overcome, real - world case studies, and the exciting future prospects. Whether you're an aviation enthusiast, an industry professional, or simply curious about the latest technological advancements, read on to discover the transformative power of 3D printed airplane parts.

The Basics of 3D Printed Airplane Parts

What is 3D Printing?

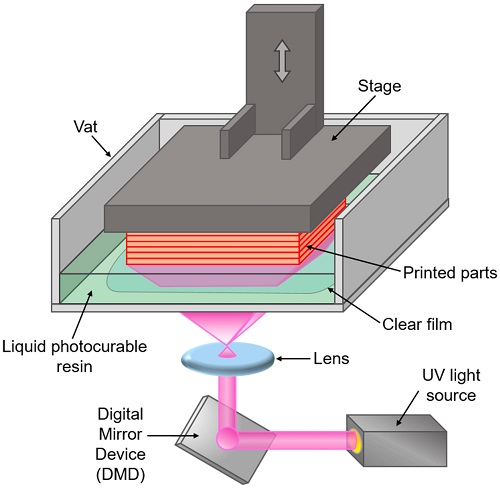

3D printing, also known as additive manufacturing, is a revolutionary technology that constructs three - dimensional objects by layering materials based on a digital model. The process starts with a 3D design created using computer - aided design (CAD) software. This digital file is then sliced into thin cross - sectional layers by the 3D printer's software.

The printer reads these layer - by - layer instructions and deposits or fuses the chosen material, such as plastic, metal, or ceramic, one layer at a time. For example, in fused deposition modeling (FDM), which is one of the most common 3D printing methods, a spool of thermoplastic filament is melted and extruded through a nozzle. The nozzle moves precisely according to the design, depositing the melted material in the right places to build up the object layer upon layer. This additive approach is a stark contrast to traditional manufacturing methods like machining, which often involve subtracting material from a larger block to create the desired shape, leading to significant material waste.

How are 3D Printed Airplane Parts Made?

When it comes to making 3D printed airplane parts, the first step is the design phase. Engineers use advanced CAD software to create highly detailed 3D models of the parts. These models are not only designed to meet the functional requirements of the aircraft but also take into account the unique capabilities and limitations of 3D printing technology. For instance, complex internal geometries that would be extremely difficult or impossible to achieve with traditional manufacturing can be easily designed for 3D printing.

Once the design is complete, the appropriate 3D printing technology and material are selected. In the aviation industry, materials need to meet strict safety and performance standards. Common materials used for 3D printed airplane parts include high - strength plastics like polyetheretherketone (PEEK), which offers excellent heat resistance and mechanical properties, and various metals such as titanium alloys. Titanium is favored for its high strength - to - weight ratio, corrosion resistance, and ability to withstand the harsh conditions of flight.

For metal 3D printing, processes like selective laser melting (SLM) are often employed. In SLM, a high - power laser is used to melt and fuse metal powder layer by layer according to the digital model. This results in a fully dense metal part with precise dimensions. After the printing process is finished, the parts usually undergo post - processing steps. This may include heat treatment to improve the material's mechanical properties, machining to achieve the final required tolerances, and surface finishing to enhance the part's appearance and corrosion resistance.

Case Studies of 3D Printed Airplane Parts in Use

SpaceX's Application

SpaceX, a leader in the aerospace industry, has been at the forefront of adopting 3D printing technology for rocket parts. In their Falcon 9 rockets, they have used 3D printed components such as the main oxidizer valve (MOV) body in the Merlin 1D engines. This 3D printed part has proven to function flawlessly under high - pressure liquid oxygen conditions, as well as endure high vibrations and low temperatures.

The use of 3D printed parts by SpaceX has led to significant cost savings. For instance, traditional manufacturing methods for such complex parts often involve multiple steps, expensive tooling, and a high amount of material waste. By contrast, 3D printing allows for a more streamlined production process. The cost of manufacturing certain engine parts through 3D printing can be reduced by up to 50% compared to traditional methods. This cost - effectiveness enables SpaceX to offer more competitive launch services in the market.

In terms of performance, 3D printed parts can be designed with optimized geometries. For example, the internal channels and structures of 3D printed engine components can be precisely engineered to enhance fuel flow and combustion efficiency. This has led to a boost in the overall performance of the Falcon 9 rockets, allowing them to achieve higher thrust - to - weight ratios and more efficient space missions.

NASA's Research and Development

NASA has also made remarkable strides in using 3D printing for rocket engine components. One of the notable achievements is the development of 3D printed rocket engines like the RS - 25 engine with 3D printed fuel nozzles. These nozzles are not only lighter in weight but also can withstand the extremely high temperatures and pressures generated during rocket launches.

The development of 3D printed rocket engines by NASA has shortened the production time significantly. In the past, manufacturing a rocket engine could take months or even years, involving complex machining and assembly processes. With 3D printing, the production time of some engine components has been reduced by 75%. This acceleration in production allows NASA to conduct more frequent tests and development cycles, leading to faster technological advancements.

Moreover, the use of 3D printing in engine manufacturing has enabled NASA to explore more innovative designs. The technology allows for the creation of intricate internal cooling channels in the engine components. These channels help in dissipating heat more effectively, which is crucial for the long - term reliability and performance of the engines during the intense heat - generating space missions. Overall, NASA's research and development in 3D printed rocket parts are paving the way for more efficient, cost - effective, and powerful space exploration in the future.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology is highly optimistic about the prospects of 3D printed airplane parts. The ability to create complex geometries with high - strength materials aligns well with our expertise in custom manufacturing. We believe that as 3D printing technology in aviation continues to evolve, there will be more opportunities for cooperation in material research and development. Our company is eager to contribute to the supply of specialized materials that can meet the stringent requirements of 3D printed airplane parts production. We are also interested in collaborating on the technological innovation of 3D printing processes, aiming to further enhance the quality and efficiency of manufacturing these critical aviation components.

FAQ

1. Are 3D printed airplane parts as safe as traditionally manufactured parts?

Yes, 3D printed airplane parts are as safe as traditionally manufactured ones. Stringent testing and certification processes are in place to ensure their safety. For example, they undergo fatigue testing, which simulates the repeated stress the parts will experience during flight over a long period. They also go through material property testing to verify that the 3D printed materials meet the required strength, durability, and heat - resistance standards. In fact, many 3D printed parts have been certified by aviation authorities such as the Federal Aviation Administration (FAA) in the United States, indicating that they are deemed just as safe for use in aircraft as traditionally made parts.

2. What types of airplane parts can be 3D printed?

A wide variety of airplane parts can be 3D printed. Engine components like fuel nozzles, which need to withstand high temperatures and pressures, are often 3D printed. These nozzles can be designed with complex internal channels for better fuel atomization and combustion efficiency. Wing structure parts such as brackets and ribs can also be 3D printed. Their optimized geometries can reduce weight while maintaining structural integrity. Interior components like seat brackets, overhead bin parts, and ventilation ducts are common 3D printed items. They can be customized to fit specific cabin designs and passenger comfort requirements.

3. How much can 3D printing reduce the cost of airplane part production?

3D printing can reduce the cost of airplane part production by approximately 30% - 50% in many cases. However, this cost reduction is influenced by multiple factors. The complexity of the part plays a significant role. For highly complex parts with intricate geometries, the cost savings can be more substantial as traditional manufacturing would require expensive multi - step processes and custom tooling. Material costs also matter. Some 3D printing materials are still relatively expensive, but as the technology advances and the market grows, material prices are gradually decreasing. Additionally, the production volume affects cost. For low - volume production, 3D printing is often more cost - effective since it doesn't require the high - cost setup associated with traditional mass - production methods.