1. Introduction

What exactly is additive manufacturing powder bed fusion (PBF)? Additive manufacturing, also known as 3D printing, is a revolutionary technology that builds three - dimensional objects by layering materials based on a digital model. Powder bed fusion, a subset of additive manufacturing, is a process where thermal energy selectively fuses regions of a powder bed.

This technology has gained significant traction across various industries due to its unique capabilities. For instance, in the aerospace industry, parts produced via powder bed fusion can be designed with complex internal geometries that are impossible to achieve through traditional manufacturing methods. This not only reduces the weight of components but also improves their performance, leading to more fuel - efficient aircraft. In the medical field, custom - made implants can be created to fit individual patients precisely, enhancing the success rate of surgeries.

2. How Powder Bed Fusion Works

2.1 Basic Process

The powder bed fusion process begins with spreading a thin layer of powdered material, which can be metal, plastic, ceramic, or composite powder, evenly across a build platform. This is typically done using a recoater blade or a roller. For example, in metal powder bed fusion for aerospace component production, a layer of titanium powder with a thickness usually ranging from 20 - 100 micrometers is precisely spread.

Once the powder layer is in place, an energy source comes into play. The energy source selectively heats and fuses the powder particles in the areas defined by the digital 3D model. After the first layer is melted and solidified, the build platform is lowered by a distance equal to the layer thickness. Another layer of powder is spread, and the energy - melting process is repeated. This sequential layering and fusing continue until the entire 3D object is formed.

2.2 Energy Sources

Two of the most commonly used energy sources in powder bed fusion are lasers and electron beams.

Lasers:

- Advantages: Lasers offer high precision and can achieve fine feature resolution, often down to 50 - 100 micrometers. They are suitable for a wide range of materials, including metals, plastics, and ceramics. For instance, in the dental industry, laser - based powder bed fusion is used to create highly detailed dental crowns and bridges with complex geometries. Lasers can also be focused accurately, allowing for the creation of complex internal structures such as lattice patterns, which are beneficial for lightweight and high - strength designs in the aerospace and automotive industries.

- Disadvantages: Laser - based systems can be relatively slow, especially when building large - scale parts. They also require a significant amount of energy, which can lead to high operating costs. Additionally, the laser optics need regular maintenance to ensure optimal performance, and the initial investment in laser - equipped powder bed fusion machines is quite high.

Electron Beams:

- Advantages: Electron beam powder bed fusion (EBPBF) is much faster than laser - based systems, making it suitable for high - volume production. It also operates in a vacuum environment, which is advantageous when working with reactive materials like titanium. The vacuum helps prevent oxidation and contamination during the melting process. EBPBF can achieve high deposition rates, enabling the rapid construction of large components, such as the titanium landing gear components in some aircraft.

- Disadvantages: Electron beam systems are more complex and require a vacuum chamber, which increases the overall size and cost of the equipment. The electron beam technology is also more limited in terms of the materials it can process compared to lasers, and the precision may not be as high as laser - based systems, typically with a feature resolution in the range of 100 - 200 micrometers.

3. Materials Used in Powder Bed Fusion

3.1 Metal Powders

A variety of metal powders are suitable for powder bed fusion processes.

- Titanium Alloys: Titanium alloys, such as Ti - 6Al - 4V, are widely used in aerospace and medical applications. They offer an excellent strength - to - weight ratio, high corrosion resistance, and good biocompatibility. In the aerospace industry, components like engine parts and structural elements are produced using PBF with titanium alloy powders. For example, the landing gear components of some aircraft are made through this process, reducing weight by up to 30% compared to traditional manufacturing methods while maintaining high strength and durability.

- Aluminum Alloys: Aluminum alloys are popular for their low density and good thermal conductivity. Alloys like AlSi10Mg are commonly used in automotive and aerospace for applications such as engine blocks, heat exchangers, and structural components. In the automotive industry, 3D - printed aluminum alloy engine components can improve fuel efficiency due to their reduced weight, with weight savings of about 15 - 20% compared to conventionally - made parts.

- Stainless Steels: Stainless steels, including 316L and 17 - 4PH, are used in a wide range of applications due to their corrosion resistance and mechanical properties. In the food and beverage industry, 316L stainless steel is used to create custom - designed mixing components and valves via PBF. These components can be designed with complex internal channels for better fluid flow, improving the efficiency of production processes.

3.2 Other Materials

Beyond metals, other powder materials are also used in powder bed fusion.

- Plastic Powders: Plastic powders, such as nylon (PA12) and polypropylene (PP), are used in applications where lightweight, cost - effective parts are required. In the consumer goods industry, nylon powder is used to 3D - print custom - designed casings for electronics. These casings can be printed with complex geometries to provide better ergonomics and heat dissipation, and they are often 30 - 40% lighter than traditional injection - molded plastic parts.

- Ceramic Powders: Ceramic powders are used for applications that require high - temperature resistance, wear resistance, and chemical stability. For example, in the aerospace and electronics industries, ceramic powders are used to create components like turbine blades for high - temperature engines and insulating parts for electronic devices. However, ceramic powder bed fusion is more challenging due to the high melting points and brittleness of ceramics, often requiring special processing techniques and post - processing treatments.

4. Applications of Powder Bed Fusion

4.1 Aerospace

In the aerospace industry, powder bed fusion has become a game - changer. One of the key applications is in the manufacturing of complex engine components. For example, GE Aviation uses powder bed fusion to produce fuel nozzles for its LEAP engines. These nozzles have intricate internal channels that are designed to improve fuel - air mixing, leading to more efficient combustion. By using PBF, GE was able to reduce the number of parts in the nozzle from 20 to just 1, significantly improving reliability and reducing weight by up to 25%.

Another application is in the production of lightweight structural components. Spacecraft need to be as light as possible to reduce the amount of fuel required for launch. Powder bed fusion allows for the creation of components with lattice - like internal structures. These structures provide high strength while minimizing weight. For instance, some small - satellite manufacturers are using PBF - produced aluminum alloy components with lattice structures, which can reduce the weight of the satellite's structure by 40 - 50% compared to traditional manufacturing methods.

4.2 Automotive

In the automotive industry, powder bed fusion is being used for both custom - made and high - performance parts. For custom - made parts, car enthusiasts can now design and 3D - print unique interior components such as gear knobs, dashboards, or custom - fitting spoilers. This allows for a high degree of personalization that was previously not cost - effective with traditional manufacturing.

For high - performance parts, PBF is used to create lightweight and high - strength components. For example, some supercar manufacturers are using 3D - printed titanium alloy suspension components. These components can be designed with optimized geometries to improve handling and reduce unsprung weight. The weight reduction of these components can be around 30 - 40%, which in turn improves the vehicle's acceleration, braking, and fuel efficiency. Additionally, PBF enables rapid prototyping in the automotive industry. Designers can quickly produce and test new part designs, reducing the time it takes to bring a new vehicle model to market. A new prototype part can be printed and tested within a few days, compared to weeks or months with traditional prototyping methods.

4.3 Healthcare

In the healthcare field, powder bed fusion is revolutionizing the production of personalized implants and 医疗器械. One of the most significant applications is in the creation of custom - made orthopedic implants. For patients with complex bone fractures or bone diseases, traditional off - the - shelf implants may not fit properly. With powder bed fusion, doctors can create implants that are tailored to the patient's specific anatomy. For example, 3D - printed titanium alloy hip implants can be designed to match the patient's bone structure precisely, improving the implant's stability and reducing the risk of implant failure. These custom - made implants can also lead to better patient outcomes, with faster recovery times and reduced pain.

Another application is in the production of dental implants and prosthetics. PBF allows for the creation of highly detailed and accurate dental crowns, bridges, and dentures. These 3D - printed dental products can fit better in the patient's mouth, providing a more comfortable and natural - looking solution. Additionally, the use of PBF in the production of surgical instruments is on the rise. Custom - designed surgical instruments can be created to suit the specific needs of a surgical procedure, improving the precision and success rate of surgeries.

5. Yigu Technology's View

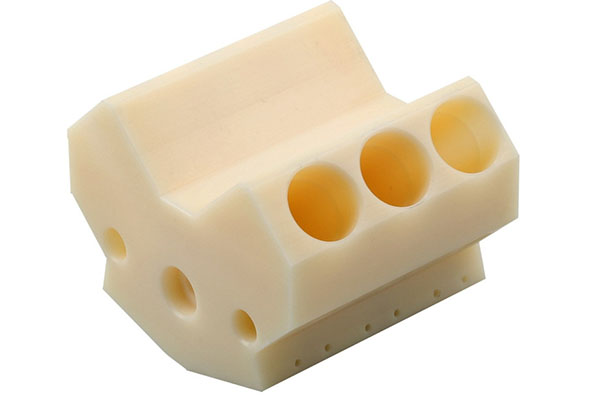

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values additive manufacturing powder bed fusion technology. In custom - made production, this technology offers significant advantages. It allows for the creation of complex and unique product structures that traditional manufacturing methods struggle to achieve, meeting the diverse needs of customers. For example, when producing custom - designed plastic - metal composite parts, powder bed fusion can precisely control the combination of different materials at the micro - level, enhancing the functionality and performance of the products.