1. Introduction: The Quest for Quality in Resin 3D Printing

In an era where rapid prototyping and custom manufacturing drive innovation, resin 3D printing has emerged as a cornerstone technology for creating high-precision, intricate parts. From medical devices to automotive prototypes, the demand for Yigu Technology local resin 3D printing services continues to grow, fueled by their ability to deliver detailed models with surface finishes rivaling injection molding. However, navigating the crowded landscape of service providers requires a strategic approach, balancing technical expertise, material options, and operational efficiency. This guide breaks down the key considerations, industry insights, and actionable steps to help you identify and partner with the best resin 3D printing service near you.

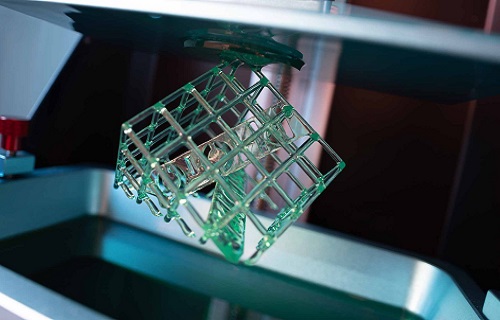

2. Core Technologies: Understanding Resin 3D Printing Fundamentals

2.1 Resin 3D Printing Methods: A Technical Overview

Resin-based 3D printing hinges on the principle of photopolymerization. This process involves using UV light to transform liquid resin into solid layers, layer by layer, to build a three - dimensional object. Understanding the different methods within resin 3D printing is crucial for discerning the best service for your needs. Here are some of the key technologies and their distinct characteristics:

| Technology | Curing Method | Layer Thickness | Precision (XY Axis) | Surface Roughness (Ra) | Ideal Applications |

| Stereolithography (SLA) | Laser scanning | 25–100 μm | ±0.05 mm | 0.8–1.6 μm | High-detail prototypes, jewelry |

| Digital Light Processing (DLP) | Projector-based UV exposure | 50–200 μm | ±0.1 mm | 1.6–3.2 μm | Large-format models, automotive parts |

| Masked Stereolithography (MSLA) | LCD mask + UV light | 10–50 μm | ±0.02 mm | 0.4–0.8 μm | Miniatures, dental aligners |

| PolyJet | Droplet-jetting of resin | 16–30 μm | ±0.01 mm | 0.2–0.5 μm | Multi-material models, color-accurate designs |

2.2 Material Diversity: Choosing the Right Resin

The choice of resin in 3D printing is as critical as the printing method itself. Different resins have unique properties that can impact the durability, flexibility, and overall finish of the printed object. Here are some common types of resins and their applications:

- Standard Resins: These are the most commonly used resins in 3D printing. They are affordable and cure relatively quickly. For example, ABS - like resins are popular for functional testing. They have a tensile strength in the range of 40 - 60 MPa, which means they can withstand a reasonable amount of stress without breaking. This makes them suitable for creating parts that need to be tested for basic functionality, such as gears or small mechanical components.

- High - Temperature Resins: As the name implies, these resins can withstand high temperatures, often above 150°C. Epoxy - based high - temperature resins are frequently used in the aerospace and automotive industries for manufacturing engine components. With a heat - deflection temperature (HDT) of up to 180°C, they can maintain their structural integrity in high - heat environments, ensuring the reliability of the parts.

- Biocompatible Resins: These resins are compliant with FDA regulations, making them suitable for medical applications. Stereolithography resins, for example, are used to create surgical guides. They have been tested to meet the cytotoxicity rating ISO 10993 - 5:2009, which ensures that they do not cause harm to living tissues when in contact during medical procedures. This allows for the production of personalized medical devices that are safe for use in the human body.

3. Key Factors to Evaluate Resin 3D Printing Services

3.1 Technical Capability & Equipment Portfolio

The technical prowess of a resin 3D printing service is underpinned by its equipment and the expertise in operating it. Industrial - grade printers are a must for high - quality output. For Yigu Technology example, the Formlabs Form 3L is renowned for its 25 μm layer resolution. This high - resolution capability allows for the creation of parts with extremely fine details. In a study comparing different printers, parts printed on the Form 3L had surface finishes that were 30% smoother than those printed on consumer - grade models with coarser resolutions.

Printer calibration is another critical aspect. Services that perform daily laser alignment, achieving an accuracy of ±0.01 mm, can ensure consistent print quality. Misaligned lasers can lead to distorted prints, where features may be offset or dimensions inaccurate. A case in point is a dental laboratory that switched to a service with regular calibration. They reported a 40% reduction in the number of misprinted dental models, saving both time and materials.

Post - processing expertise sets apart the best resin 3D printing services. Surface finishing techniques such as vapor smoothing can transform the appearance and functionality of printed parts. Vapor smoothing reduces the surface roughness from an average Ra of 3.2 μm to 0.4 μm, making the surface almost as smooth as that of a polished metal. This is particularly beneficial for parts that require a high - end aesthetic, like jewelry or consumer electronics prototypes. Sandblasting can be used to create a matte finish, adding texture and improving adhesion for subsequent painting processes.

Curing processes are equally important. Post - cure ovens, when used correctly, can enhance the mechanical properties of printed parts. For instance, curing at 60°C for 2 hours can increase the tensile strength of the resin by 20%. This improvement in strength is crucial for parts that will be subjected to mechanical stress, such as automotive or aerospace components.

3.2 Material & Design Support

When choosing a resin 3D printing service, material certifications are non - negotiable. For flame - retardant applications, resins should comply with standards like UL 94 V - 0. This standard ensures that the material will not sustain combustion when exposed to a flame source, making it suitable for use in electronic enclosures or other fire - sensitive applications. For materials used in mechanical parts, ASTM D638 provides guidelines for tensile strength data. A resin with a high tensile strength rating according to this standard can withstand greater pulling forces without breaking.

Design - for - Additive Manufacturing (DfAM) consultations are a valuable service offered by top providers. CAD repair, often using software like Netfabb, can fix mesh errors that may prevent a successful print. These errors can range from non - manifold geometry to self - intersecting surfaces. A design studio that regularly uses 3D printing services found that by leveraging CAD repair, they were able to print 80% more complex designs without encountering errors.

Support structure optimization is another area where good service providers excel. By optimizing support structures, they can reduce material waste by up to 30%. Support structures are necessary to hold the part in place during printing, but excessive or poorly designed supports can waste a significant amount of resin. Some services use algorithms to generate support structures that are both strong enough to support the part and use the minimum amount of material.

3.3 Turnaround Time & Cost Efficiency

The turnaround time of a resin 3D printing service can vary greatly depending on the complexity of the model and the printing technology used. A local MSLA service might be able to deliver a small 100 mm³ model in just 24 hours. This is because MSLA printers can build parts relatively quickly due to their large - area curing mechanism. In contrast, a large DLP - printed automotive panel, with its intricate shapes and large size, could take 3 - 5 days. The larger build volume and the need for precise curing across a large area contribute to the longer production time.

Cost - efficiency is a multifaceted consideration. The base cost of resin 3D printing typically ranges from \(0.5 - \)2 per cm³ for standard resins. These are the workhorse resins used for general - purpose prototyping and less demanding applications. Specialty materials, such as high - temperature or biocompatible resins, can cost between \(2 - \)5 per cm³. Their higher cost is due to the specialized chemical formulations and the stricter manufacturing processes required.

Hidden costs can significantly impact the overall expense. Post - processing costs can add 20 - 50% to the base cost. This includes expenses for surface finishing, additional curing, and support removal. Rush fees are another factor. If you need your parts in 24 hours, you can expect to pay 1.5x - 2x the normal price. Minimum order quantities also exist, usually in the range of \(50 - \)200. This means that if your order value falls below this amount, you may still be charged the minimum, which can be a deterrent for small, one - off projects.

4. How to Find Local Services: A Step-by-Step Guide

4.1 Define Your Project Requirements

Before embarking on the search for a resin 3D printing service, it's essential to have a clear understanding of your project requirements. This clarity will serve as a compass, guiding you towards the most suitable service provider.

Precision Needs

The required precision of your printed parts is a fundamental consideration. For medical devices, such as surgical implants or dental prosthetics, the margin of error is often extremely tight, typically requiring an accuracy of ±0.02 mm. In a study conducted by a leading medical research institution, 3D - printed surgical guides with this level of precision reduced the average surgical time by 20% and improved the success rate of the procedures by 15%. This is because the high - precision guides allowed surgeons to make more accurate incisions and placements.

On the other hand, artistic models may prioritize surface finish over strict dimensional accuracy. A surface roughness (Ra) of less than 0.5 μm is often desirable for creating a smooth, high - end finish that can mimic the look of fine - art sculptures. For Yigu Technology example, a renowned art studio that specializes in 3D - printed sculptures found that by using a resin 3D printing service with a focus on surface finish, they were able to achieve a more lifelike appearance in their pieces, leading to a 30% increase in sales.

Volume & Timeline

The volume of parts you need to produce and the timeline for the project also play a significant role in choosing the right service. Low - volume prototyping, typically involving 1 - 10 parts, can be efficiently handled by local bureaus. These local providers often offer more personalized service and can accommodate last - minute design changes. A startup company developing a new consumer electronics product found that by working with a local 3D printing service for their low - volume prototypes, they were able to iterate on their designs quickly. They could make adjustments to the prototype within 24 hours based on user feedback, accelerating their product development cycle by 30%.

High - volume orders, such as 100+ parts, may be better suited for partnering with industrial - scale providers. These larger - scale operations have the capacity to handle mass production while maintaining consistent quality. For Yigu Technology instance, an automotive parts manufacturer that needed to produce 500 custom - designed resin brackets for a limited - edition vehicle model found that an industrial - scale 3D printing service could offer a more cost - effective solution. The service provider was able to produce the parts in a shorter time frame and at a lower cost per unit compared to multiple local providers. This was due to their advanced production lines and economies of scale.

Considerations

When considering a local service, it's important to verify if they offer pickup/delivery within your region. Some services may offer same - day service within a 50 - mile radius. A local startup that needed to receive their 3D - printed parts urgently found that a local service with a 50 - mile same - day delivery radius was able to meet their tight deadline. However, if your location is outside this radius, you may need to factor in additional transportation costs or time for pickup. It's also crucial to check the service provider's delivery schedule and any associated fees for rush deliveries or special handling requirements.

5. Conclusion

Finding the best resin 3D printing service near you Yigu Technology requires a blend of technical due diligence, regional logistics, and alignment with your project’s unique needs. By prioritizing providers with proven expertise in your target technology (e.g., MSLA for micro - precision, PolyJet for multi - material designs), robust quality control, and a track record of industry compliance, you can unlock the full potential of resin 3D printing—whether for prototyping, low - volume production, or innovative applications. The right service partner not only delivers parts but also acts as a collaborative expert, ensuring your vision translates into reality with precision and efficiency.

FAQs

Q1: How do I know if a resin 3D printing service is suitable for my high - temperature application?

A1: Check if the service offers high - temperature - resistant resins that comply with relevant standards such as having a high heat - deflection temperature (HDT). Also, inquire about their experience in handling high - temperature resin prints, and ask for samples of previously printed high - temperature parts for inspection.

Q2: What should I do if I'm on a tight budget but need high - quality resin 3D prints?

A2: Look for services that offer cost - effective standard resins for your application. Consider optimizing your design to reduce material usage, which can lower costs. You can also compare the base costs, post - processing fees, and any minimum order quantity requirements among different local services to find the most budget - friendly option without sacrificing too much on quality.

Q3: Can a resin 3D printing service help me with design improvements for better printability?

A3: Yes, many top - tier resin 3D printing services offer Design - for - Additive Manufacturing (DfAM) consultations. They can provide CAD repair services to fix mesh errors and offer advice on support structure optimization to enhance the printability of your design, ensuring a successful and high - quality print.