Plastic & Metal industry knowledge

Transfer the value information of rapid prototypes, mold and injection molding industry

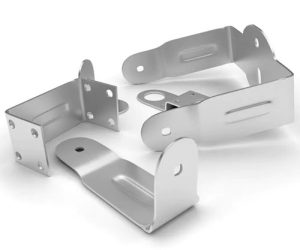

Sheet Metal Cold-Rolled Steel: Properties, Processes, Practical Applications

Introduction Manufacturers and fabricators often face a range of challenges when selecting materials for their projects. When it comes to sheet metal, common pain points include finding a material that...

Die Casting Lead-Based Alloys: A Comprehensive Guide to Properties, Processes, Applications

Introduction In the realm of metal casting, manufacturers often face a series of challenges when working with specific alloys. For those dealing with lead-based alloys, common pain points include ensuring...

Die Casting Pewter (Sn - Sb - Cu): A Comprehensive Exploration of Material, Process, Applications, Benefits

Introduction In the world of metal casting, manufacturers often grapple with several pain points. Quality issues such as porosity, shrinkage, and surface roughness can plague the final products, affecting their...

Die Casting Lead & Tin Alloys: Versatile Materials for Precision and Solderability

You’ve turned to lead-tin alloys for their exceptional solderability and casting fluidity, expecting parts that excel in electrical connectors and precision components. But your production is facing issues: the molten...

Die Casting Bronze (Cu-Sn): The Wear-Resistant Alloy for Heavy-Duty Applications

You’ve chosen bronze (Cu-Sn) for its legendary wear resistance and corrosion resistance, expecting parts that excel in bearings and heavy-duty gears. But your production is facing hurdles: the molten bronze’s...

Die Casting Brass (Cu-Zn): The Versatile Alloy for Conductive and Corrosive Applications

You’ve chosen brass (Cu-Zn) for its unbeatable combination of electrical conductivity, corrosion resistance, and workability, expecting parts that excel in plumbing components and electrical connectors. But your production is hitting...

Die Casting Copper Alloys: Conductive Strength for Critical Applications

You’ve turned to copper alloys for their unrivaled electrical and thermal conductivity, expecting parts that deliver reliable performance in electrical connectors and heat-dissipating components. But your production is facing challenges:...

Die Casting AM50A: Balanced Magnesium Alloy for Versatile Applications

You’ve selected AM50A magnesium alloy for its reputation as a balanced material, expecting parts that combine moderate strength, good ductility, and reliable corrosion resistance for automotive parts and consumer products....

Die Casting AM60B: The Ductile Magnesium Alloy for Impact-Resistant Parts

You’ve chosen AM60B magnesium alloy for its reputation as a ductile, impact-resistant material, expecting parts that can absorb energy without breaking—ideal for automotive parts like door beams and bumpers. But...

Die Casting AZ91D: The Workhorse Magnesium Alloy for High-Volume Production

You’ve selected AZ91D magnesium alloy for its reputation as the most versatile magnesium die casting material, expecting parts that balance strength, light weight, and cost for high-volume applications. But your...

Die Casting Magnesium Alloys: Ultra-Light Strength for Modern Engineering

You’ve turned to magnesium alloys for their unrivaled strength-to-weight ratio, expecting parts that slash weight without sacrificing durability for aerospace components and electric vehicles. But your production is hitting roadblocks:...

Die Casting A356: High-Strength Aluminum for Precision Applications

You’ve chosen A356 aluminum alloy for its reputation as a high-strength, corrosion-resistant material, expecting parts that balance durability and light weight for aerospace components and engine parts. But your production...

Die Casting A390: High-Silicon Aluminum for Extreme Wear Applications

You’ve turned to A390, a high-silicon aluminum alloy, for its reputation as the most wear-resistant aluminum die casting alloy, expecting parts that can withstand constant friction and high temperatures. But...

Die Casting A360: Corrosion-Resistant Aluminum Alloy for Demanding Environments

You’ve chosen A360 aluminum alloy for its reputation as a corrosion-resistant, high-performance material, expecting parts that can withstand harsh environments while maintaining strength. But your production is facing issues: the...

Die Casting A383 (ADC12): The Global Workhorse Aluminum Alloy

You’ve selected A383 (also known as ADC12 in Asian standards) for its reputation as a cost-effective, high-fluidity aluminum alloy, expecting parts that balance strength and production efficiency. But your operation...

Die Casting A380: The Workhorse Aluminum Alloy for Precision Parts

You’ve chosen A380 aluminum alloy for its reputation as a reliable, all-purpose die casting material, expecting parts with consistent flow, strength, and finish. But your production line is hitting snags:...

Die Casting Aluminum Alloys: Lightweight Strength for Modern Manufacturing

You’ve chosen aluminum alloys for their unbeatable combination of light weight and strength, expecting die cast parts that reduce weight without sacrificing durability. But your production is facing hurdles: the...

Die Casting ZA (Zinc-Aluminum): High-Strength Zinc Alloys for Demanding Applications

You’ve turned to zinc-aluminum alloys (ZA) for their promise of higher strength than standard ZAMAK, expecting parts that can handle heavier loads and higher temperatures. But your production is struggling:...

Die Casting ZAMAK (Zn-Al-Cu-Mg): The Gold Standard of Zinc Alloys

You’ve chosen ZAMAK for its reputation as a high-performance zinc alloy, expecting parts with consistent strength, smooth finishes, and easy castability. But your production line is struggling: some castings are...

Die Casting Zinc Alloys: Strength, Precision, and Affordability

You’ve chosen zinc alloys for die casting, drawn to their reputation for high precision and low cost. But your parts are falling short: the castings have unsightly pores that weaken...