Introduction

In the dynamic field of engineering, 3D printing has emerged as a revolutionary technology, offering engineers a world of possibilities. It has transformed the way products are designed, prototyped, and even manufactured. With 3D printing, engineers can bring their most intricate ideas to life, break free from the constraints of traditional manufacturing methods, and accelerate the development process.

This article delves into a variety of 3D printing projects tailored for engineers. Whether you are a seasoned professional looking to explore new applications or a budding engineer eager to gain hands - on experience, these projects will not only enhance your skills but also open up new avenues in the exciting realm of 3D printing.

3D Printing Projects Examples

DIY Camera Slider

A DIY camera slider is an excellent project for engineers interested in the intersection of mechanical engineering and 3D printing. The principle behind a camera slider is to provide a smooth, linear motion for a camera, allowing for the creation of professional - looking tracking shots in photography and videography.

To make a DIY camera slider using 3D printing, you first need to design the components. This includes the base, the rails, the carriage that holds the camera, and any necessary mounting brackets. For example, the rails could be designed with a T - shaped cross - section to ensure smooth movement of the carriage, and the carriage itself should have bearings or bushings to reduce friction. Once the design is complete, you can print these components using a 3D printer. Materials like PLA or PETG are commonly used due to their ease of printing and relatively high strength. After printing, you assemble the parts, add any additional hardware such as screws, nuts, and bolts, and then attach the camera. This project helps engineers to understand mechanical design principles, such as motion transfer, friction reduction, and load - bearing capacity, while also getting hands - on experience with 3D printing technology.

Engineering Model

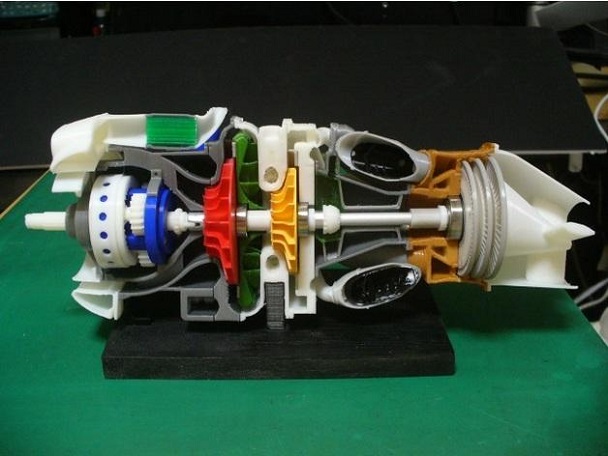

The process of making an engineering model with 3D printing begins with a detailed design phase. Engineers use CAD (Computer - Aided Design) software to create a 3D model of the object they want to represent. For instance, if it's a complex mechanical part, they will define all the dimensions, shapes, and internal structures accurately.

Once the CAD model is ready, it is converted into a format that the 3D printer can understand, usually STL (Stereolithography) format. Then, the 3D printing process starts. Different types of 3D printers, such as FDM (Fused Deposition Modeling), SLA (Stereolithography Apparatus), or SLS (Selective Laser Sintering), can be used depending on the requirements of the model, like material properties and precision. After the printing is complete, post - processing steps may be needed, such as removing support structures, sanding, and painting.

Engineering models created through 3D printing are invaluable for understanding complex structures. They allow engineers to visualize and analyze how different parts fit together, identify potential design flaws, and optimize the design. For example, in the design of an aircraft engine, a 3D - printed model can help engineers study the flow of air through the engine's components, enabling them to make improvements to increase efficiency.

Custom Camera Gear

When it comes to custom camera gear, the design 思路 is centered around the specific needs of the user. For example, a photographer might want a custom - designed lens hood that is not only functional but also fits a particular camera model perfectly. Using 3D printing, engineers can create a lens hood with unique shapes and features. They can start by measuring the camera lens diameter and the desired length and shape of the hood. Then, in the CAD software, they design the lens hood, adding features like anti - glare ridges or a collapsible structure for easy storage.

3D printing excels in meeting these 个性化需求. Traditional manufacturing methods often have high costs and long lead times for custom products, but 3D printing can quickly produce one - off or small - batch custom camera gear. It allows for the integration of complex geometries and the use of a variety of materials, such as flexible filaments for parts that require some degree of flexibility, like camera grips. This not only provides photographers with unique and tailored equipment but also gives engineers the opportunity to experiment with innovative designs.

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology sees great potential in 3D printing for custom - made production. 3D printing allows for the creation of highly customized products that precisely meet clients' unique requirements. This not only reduces waste but also shortens the production cycle, especially beneficial for small - batch and one - off projects.

However, there are challenges. The limited range of printable materials restricts the application scope, and the relatively high cost of 3D printing, especially for large - scale production, is a hurdle. Also, ensuring consistent quality across prints can be difficult.

Looking ahead, Yigu Technology believes that with the continuous development of 3D printing technology, such as the emergence of new materials and more efficient printing processes, 3D printing will play an even more significant role in the custom - manufacturing industry. It will enable the production of more complex and high - performance non - standard products, further meeting the diverse needs of the market.

FAQ

What are the most suitable 3D printing materials for engineering projects?

For engineering projects, several materials stand out. PLA (Polylactic Acid) is popular due to its ease of printing, low toxicity, and good surface finish. It is biodegradable and sourced from renewable resources like corn or sugarcane. However, it has relatively low strength and heat resistance. ABS (Acrylonitrile Butadiene Styrene) is another common choice. It offers high strength, good heat resistance, and is durable, making it suitable for functional prototypes and parts that need to withstand mechanical stress. Metal materials such as aluminum, titanium, and stainless - steel are used for high - strength and high - performance applications. Aluminum is lightweight and corrosion - resistant, while titanium offers excellent strength - to - weight ratio and biocompatibility, which is crucial in aerospace and medical applications.

How to ensure the accuracy of 3D printed parts?

To ensure the accuracy of 3D printed parts, start with proper model design. Avoid creating overly complex geometries that could cause printing issues. Use high - resolution CAD software and make sure the model has no errors or overlapping parts. When it comes to printer settings, adjust parameters like layer height, printing speed, and temperature. A smaller layer height generally results in a more accurate and smoother surface, but it also increases printing time. Printing speed should be optimized to avoid vibrations that could affect accuracy. Temperature control is vital as incorrect temperatures can lead to inconsistent material flow. After printing, post - processing steps such as sanding, polishing, and machining can further improve the accuracy and surface finish of the parts.

Can 3D printing be used for mass production in engineering?

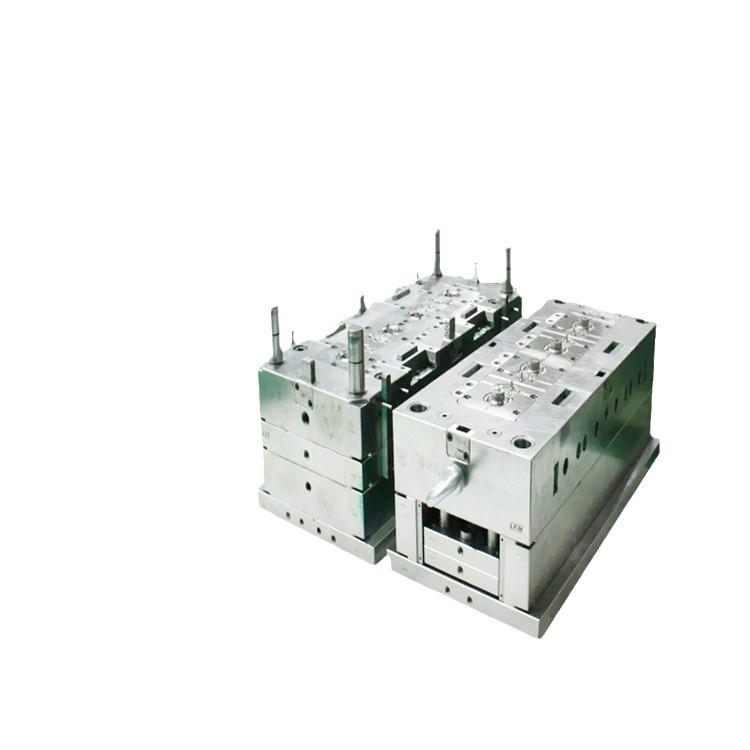

Currently, 3D printing has some limitations for mass production in engineering. The speed of 3D printing is relatively slow compared to traditional mass - production methods like injection molding or CNC machining. The cost per unit can be high, especially when using expensive materials such as high - performance plastics or metals. Also, ensuring consistent quality across a large number of prints can be challenging. However, for small - batch production or customized parts, 3D printing is highly advantageous. It allows for rapid production of unique parts without the need for expensive tooling. In the future, with the development of faster printers, more cost - effective materials, and improved quality control, 3D printing may become more viable for mass production in engineering.