Introduction

Ceramics are prized for their exceptional hardness, heat resistance, and chemical stability, but these properties make them some of the most challenging materials to machine. Manufacturers frequently struggle with ceramic material brittleness that leads to cracking, rapid tool wear due to extreme hardness, and achieving precise surface finish on delicate parts. This article addresses these pain points by exploring the ceramic materials used in CNC machining, breaking down effective processes, highlighting key applications, and discussing recent technological advancements, providing you with the expertise to navigate ceramic machining successfully.

Ceramic Materials for CNC Machining

Common Ceramic Types and Their Properties

Several ceramic materials are widely used in CNC machining, each with unique characteristics. Alumina ceramics (Al₂O₃) are the most common, offering high ceramic hardness (1500–2000 HV) and excellent ceramic thermal conductivity (20–30 W/(m·K)), making them ideal for high-temperature applications. Zirconia ceramics (ZrO₂) stand out for their ceramic toughness—up to 10 MPa·m¹/², far higher than alumina—resisting fracture in applications like ceramic bearings.

Silicon carbide ceramics (SiC) boast extreme hardness (2500–3000 HV) and thermal conductivity (80–120 W/(m·K)), suitable for abrasive and high-heat environments such as industrial nozzles. All these ceramics share ceramic material properties like chemical inertness and low electrical conductivity, but their varying hardness and toughness require tailored machining approaches.

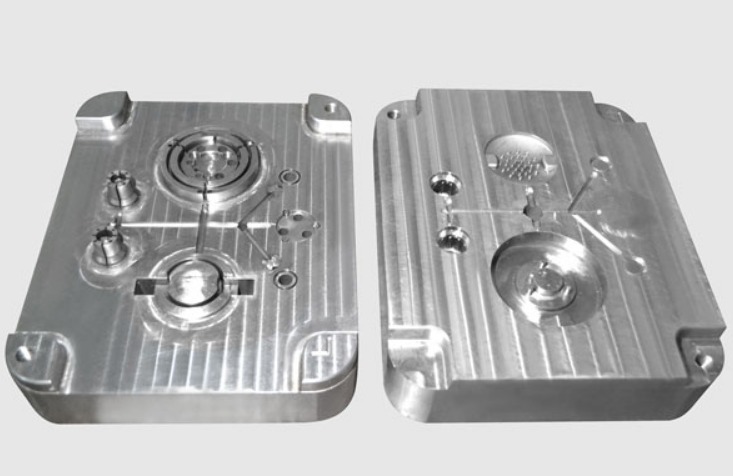

CNC Machining Processes for Ceramics

Milling, Turning, and Grinding

CNC milling ceramics demands diamond tools due to their hardness. Spindle speeds range from 5000–20000 rpm with feed rates of 0.01–0.05 mm/rev to minimize cracking. Rigid machine setups are critical to avoid vibration, which can shatter brittle ceramics.

CNC turning ceramics uses diamond-tipped inserts with negative rake angles to reduce cutting forces. Cutting speeds of 10–50 m/min and shallow depths of cut (0.1–0.5 mm) prevent chipping, while coolant (typically water-based with lubricants) dissipates heat and flushes away debris.

CNC grinding ceramics is essential for achieving precise finishes. Diamond grinding wheels with grit sizes of 80–400 mesh produce surface finish values as low as Ra 0.02 μm, suitable for sealing surfaces in medical and aerospace components.

Advanced Processes: Laser Cutting and EDM

For complex shapes, laser cutting ceramics offers precision without physical contact, reducing fracture risk. Fiber lasers with 1064 nm wavelength cut through ceramics by vaporization, achieving tight tolerances of ±0.01 mm. EDM (Electrical Discharge Machining) ceramics is another option, using electrical sparks to erode material—effective for conductive ceramics like silicon carbide.

Tool selection for ceramic machining is dominated by diamond tools: polycrystalline diamond (PCD) for milling and turning, and diamond grinding wheels for finishing. Cutting parameters for ceramics must prioritize low cutting forces and high speeds to avoid brittle failure, with adjustments based on the ceramic type—zirconia, for example, can tolerate slightly higher feeds than alumina due to its toughness.

Applications of CNC-Machined Ceramics

Aerospace, Medical, and Industrial Uses

CNC-machined ceramics excel in demanding industries. In aerospace, aerospace ceramic components like turbine blades and heat shields leverage alumina and silicon carbide’s heat resistance. The medical field uses medical implants (ceramic) such as zirconia hip and knee replacements, thanks to their biocompatibility and wear resistance.

Ceramic cutting tools made from silicon carbide outperform metal tools in machining abrasive materials, while electronic ceramic parts (alumina substrates) provide insulation in circuit boards. Automotive ceramic parts like oxygen sensors and turbocharger components use alumina’s heat resistance, and industrial ceramic nozzles (silicon carbide) withstand abrasive slurries in mining and manufacturing.

Challenges in CNC Machining Ceramics

Key Obstacles and Solutions

Ceramic material brittleness is the primary challenge—ceramics lack ductility, making them prone to cracking under uneven pressure. This requires sharp tools, low feed rates, and vibration-free setups to minimize stress. Tool wear in ceramic machining is another issue: diamond tools, while effective, wear quickly, with costs 5–10 times higher than carbide tools. Advanced tool coatings and optimized cutting paths help extend tool life.

Achieving consistent surface finish of machined ceramics is difficult due to micro-cracking. Post-machining processes like polishing and annealing reduce surface defects, ensuring reliability in critical applications. Thermal stress in ceramic machining can also cause cracking—coolant systems with precise temperature control (20–25°C) mitigate this risk by maintaining stable thermal conditions.

Advancements in Ceramic CNC Machining Technology

Recent innovations have transformed ceramic machining. Advanced ceramic machining tools like nanocrystalline diamond (NCD) coatings extend tool life by 30–50% compared to traditional PCD tools. High-speed machining of ceramics with spindle speeds up to 40000 rpm reduces cutting time while minimizing heat buildup, thanks to improved machine rigidity and dynamic balancing.

Precision CNC machines for ceramics integrate real-time monitoring systems that detect vibration and adjust feeds/speeds automatically, preventing fractures. Additive manufacturing of ceramics (3D printing) complements CNC machining, producing complex shapes that are then finish-machined for precision. Additionally, software for ceramic CNC machining now includes ceramic-specific algorithms that optimize tool paths to reduce stress and improve surface quality.

Yigu Technology's Perspective

At Yigu Technology, we specialize in CNC machining ceramics, leveraging advanced diamond tools and high-speed machining centers to tackle brittleness and tool wear. Our expertise with alumina, zirconia, and silicon carbide ensures precise parts with superior surface finish. We integrate real-time monitoring and additive manufacturing preforms to handle complex geometries, delivering reliable ceramic components for aerospace, medical, and industrial applications. Trust us to turn your ceramic machining challenges into high-performance solutions.

FAQ

- Why are diamond tools necessary for machining ceramics?

- Ceramics’ extreme hardness (1500+ HV) exceeds the capabilities of carbide tools; diamond tools (hardness 7000+ HV) are the only materials hard enough to cut them effectively.

- What is the typical tolerance achievable in ceramic CNC machining?

- With advanced processes, tolerances of ±0.005–0.01 mm are achievable, though this depends on ceramic type—zirconia’s toughness allows tighter tolerances than brittle alumina.

- How do advancements like 3D printing impact ceramic machining?

- 3D printing creates near-net-shape ceramic parts, reducing the amount of CNC machining needed, lowering costs, and enabling complex geometries that would be impossible with traditional machining alone.