Introduction

In recent years, 3D printing, also known as additive manufacturing, has been making waves across the manufacturing industry. This revolutionary technology has transformed the way products are designed, prototyped, and produced. From aerospace to automotive, healthcare to consumer goods, 3D printing is being embraced by various sectors, offering a host of benefits such as reduced production time, cost - effectiveness in small - batch production, and the ability to create highly customized and complex designs.

As the technology continues to evolve and become more accessible, the number of 3D printing applications in manufacturing is expanding at an astonishing rate. In this article, we will explore some real - world examples of 3D printing in manufacturing, highlighting how different companies and industries are leveraging this technology to gain a competitive edge. By examining these examples, you'll get a better understanding of the potential of 3D printing and how it can be applied to your own manufacturing processes.

3D Printing in Manufacturing: Examples

Rapid Prototyping

One of the most prominent applications of 3D printing in manufacturing is rapid prototyping. Take, for example, a leading consumer electronics company. When developing a new smartphone model, they used 3D printing technology to quickly create multiple prototypes of the phone's casing.

In the past, creating a prototype would involve a complex and time - consuming process of mold - making. First, a design would be created on a computer - aided design (CAD) software. Then, a mold would have to be machined from metal, which could take weeks or even months. Each time a design change was required, the mold had to be re - machined, incurring significant costs.

With 3D printing, the company was able to skip the mold - making step. The CAD models were directly fed into the 3D printer, which then built the casings layer by layer. This process reduced the time to produce a prototype from several weeks to just a few days. As a result, the development cycle of the new smartphone was shortened by nearly 30%, allowing the company to bring the product to market faster and gain a competitive edge. It also saved the company a substantial amount of money as they no longer needed to invest in expensive mold - making equipment and materials for each design iteration.

Customized Parts Production

3D printing is also a game - changer when it comes to customized parts production. Consider a medical device manufacturer that caters to patients with unique anatomical features. They often need to produce customized prosthetics or surgical instruments.

Before 3D printing, custom - made medical parts were extremely expensive and had long lead times. Traditional manufacturing methods required creating a new production line or highly customized tooling for each unique part. This involved high setup costs and long production schedules. For instance, a customized prosthetic limb would take weeks to produce, and the cost could be upwards of several thousand dollars.

However, with 3D printing, the manufacturer can create customized parts with relative ease. They use 3D scanning technology to capture the patient's unique anatomy. The data from the scan is then used to create a 3D model, which is sent to the 3D printer. The printer can then produce the customized part in a matter of hours. This not only reduces the production time significantly but also cuts down on costs. Now, the same customized prosthetic limb can be produced at a much lower cost, perhaps a few hundred dollars, and be ready for the patient in a day or two.

Small - batch Production

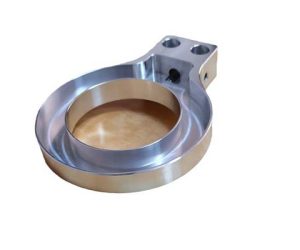

In the realm of small - batch production, 3D printing offers distinct advantages. A small - scale automotive parts manufacturer serves as a great example. This manufacturer specializes in producing rare and high - performance parts for classic and sports cars.

Previously, for small - batch production runs of these parts, the manufacturer had to rely on traditional manufacturing techniques like injection molding. Injection molding requires creating expensive molds, which are only cost - effective for large - scale production. For small - batch production, the cost per part was extremely high due to the upfront mold - making costs. If they wanted to produce 100 units of a particular part, the cost of the mold alone could be tens of thousands of dollars, making the overall production cost unfeasible.

By adopting 3D printing, the manufacturer can produce these small - batch parts without the need for expensive molds. They can quickly adjust the design for each batch according to customer requests. The production time has also been reduced. For example, a batch of 50 specialized engine components that used to take a month to produce can now be completed in just a week. This has allowed the small - scale manufacturer to be more competitive in the market, offering high - quality, customized small - batch parts at a reasonable price.

3D Printing vs Traditional Manufacturing: A Comparison

To better understand the impact of 3D printing, let's compare it with traditional manufacturing methods in several key aspects:

| Aspect | 3D Printing | Traditional Manufacturing |

| Cost for Small - batch Production | Low upfront costs as no expensive molds are needed. For a batch of 50 specialized parts, the cost can be 30 - 50% lower compared to traditional methods in some cases. | High upfront costs due to mold - making. For the same batch of 50 parts, the cost can be significantly higher, mainly because of the cost of mold production, which can range from thousands to tens of thousands of dollars depending on the complexity of the part. |

| Production Time | Can be very fast, often completing a small - batch production in a matter of days. For example, a batch of small - scale automotive parts that used to take a month can now be done in a week. | Typically longer, especially when considering the time for mold - making, setup, and production runs. For complex parts, the production time can stretch to weeks or even months. |

| Design Freedom | Allows for highly complex and customized designs with ease. Designers can create intricate geometries that were previously impossible or extremely difficult to manufacture, such as lattice structures for lightweight yet strong components. | Limited in terms of design complexity. Complex designs often require multiple manufacturing steps, special tooling, and can be very costly to produce. For instance, creating a part with internal cavities using traditional methods might involve assembly of multiple sub - parts, while 3D printing can produce it as a single piece. |

| Material Waste | Minimal as material is added only where needed. Material utilization can be as high as 90% in some 3D printing processes. | High material waste, especially in subtractive manufacturing processes like machining. In traditional metal machining, up to 70 - 80% of the raw material can be wasted as chips and scraps. |

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom Supplier, Yigu Technology firmly believes that 3D printing is revolutionizing the non - standard plastic and metal products customization industry. This technology enables us to bring our clients' complex design concepts to life with precision, meeting the diverse needs of different projects. Whether it's for creating highly customized parts for a unique industrial equipment or realizing personalized designs for consumer products, 3D printing offers a level of flexibility that traditional methods can't match.

However, we also recognize the challenges, such as limited material options in some cases and the need for continuous improvement in large - scale production efficiency. Despite these, the future of 3D printing in our field looks bright. Yigu Technology will keep a close eye on the development of 3D printing technology and actively apply it to our business, striving to provide better - quality products and more efficient services to our clients.

FAQ

What are the most common materials used in 3D printing for manufacturing?

The most common materials used in 3D printing for manufacturing include plastics like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid). ABS is known for its strength and heat - resistance, making it suitable for applications such as automotive parts prototypes and functional prototypes in various industries. PLA, on the other hand, is a biodegradable material, often used for consumer products, educational models, and in applications where environmental friendliness is a concern. Metal powders, such as stainless steel, titanium, and aluminum, are also popular, especially in aerospace and automotive industries for manufacturing high - strength components. Additionally, 光敏 resins are used in stereolithography 3D printing, ideal for creating highly detailed and accurate models, often in jewelry making, dental applications, and small - scale manufacturing of intricate parts.

Can 3D printing be used for large - scale mass production?

Currently, 3D printing faces some limitations for large - scale mass production. The printing speed is relatively slow compared to traditional mass - production methods like injection molding. For example, while a high - speed injection molding machine can produce hundreds of parts per hour, a typical 3D printer might take hours to print a single part. Also, the cost of 3D printing materials and equipment can be high, especially when considering the volume needed for mass production. However, with the continuous development of 3D printing technology, there is potential for change. Newer, faster 3D printing techniques are being developed, and as the technology matures and economies of scale are achieved, the cost may decrease, making large - scale mass production more feasible in the future.

How accurate is 3D printing in manufacturing?

The accuracy of 3D printing in manufacturing is influenced by multiple factors, including the type of 3D printing technology used, the quality of the printer, and the settings chosen. For instance, fused deposition modeling (FDM) printers typically have an accuracy in the range of 0.1 - 0.4 mm. Stereolithography (SLA) printers can achieve higher precision, often with an accuracy of around 0.05 - 0.1 mm, making them suitable for applications that require fine details. Selective laser sintering (SLS) also offers good accuracy for certain materials. To improve accuracy, factors such as proper calibration of the printer, high - quality materials, and optimized printing parameters need to be considered. Some advanced 3D printing systems are now capable of achieving sub - millimeter accuracy, meeting the requirements of many high - precision manufacturing applications.