Introduction

In today's rapidly evolving technological landscape, 3D design and printing service have emerged as revolutionary forces across various industries. But what exactly are 3D design and printing service, and why are they so crucial?

3D design involves creating three - dimensional digital models using specialized software. These models can represent anything from a small jewelry piece to a large - scale architectural structure. It allows designers to visualize and manipulate objects in a virtual space, making it easier to experiment with different shapes, sizes, and features.

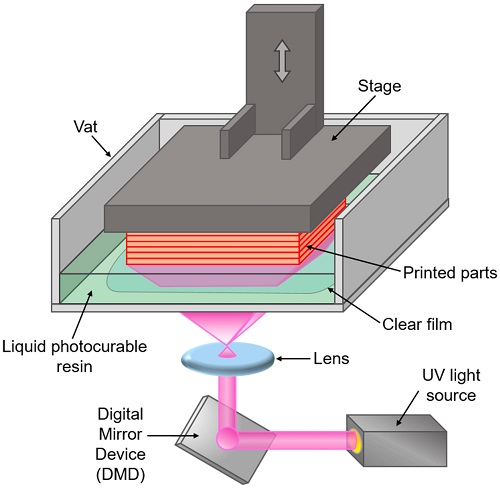

On the other hand, 3D printing, also known as additive manufacturing, is the process of turning these digital 3D models into physical objects. It works by layering materials such as plastics, metals, or ceramics based on the design specifications. This technology has opened up a world of possibilities, eliminating many of the limitations associated with traditional manufacturing methods.

The importance of 3D design and printing service cannot be overstated. In the manufacturing industry, they enable the production of complex parts with high precision and in a shorter time frame. For example, in aerospace, 3D - printed components can reduce the weight of aircraft, leading to fuel savings and increased efficiency. In healthcare, custom - made prosthetics and implants can be created to fit individual patients perfectly, improving their quality of life. The architectural and construction fields use 3D printing for creating detailed models and even building entire structures, streamlining the design - to - construction process.

As we delve deeper into this article, we will explore the different aspects of 3D design and printing service, from the types of technologies available to how they can solve specific problems in various industries, and why choosing the right service provider matters.

The Advantages of 3D Design and Printing Service

Rapid Prototyping

One of the most significant advantages of 3D design and printing service is rapid prototyping. In traditional manufacturing, creating a prototype can be a time - consuming process. For example, it might involve multiple steps such as creating molds, machining parts, and assembling them. This process could take weeks or even months.

However, with 3D design and printing, a prototype can be created in a matter of hours or days. According to a study by Wohlers Associates, in the automotive industry, the time to create a prototype has been reduced by up to 80% since the adoption of 3D printing technology. A car manufacturer was able to design and print a new engine component prototype in just 3 days, compared to the 15 days it took using traditional methods. This rapid turnaround allows companies to quickly test and iterate their designs, accelerating the overall product development cycle.

Cost - effectiveness

3D printing can be highly cost - effective, especially for small - batch production and complex designs. Consider the cost components in traditional manufacturing and 3D printing for a small - scale production of 100 custom - designed parts:

| Cost Aspect | Traditional Manufacturing | 3D Printing |

| Tooling Costs | High. Molds and dies for each part can cost thousands of dollars. | None. 3D printing is a tool - less process. |

| Material Waste | High. Traditional subtractive manufacturing often results in significant material waste. | Low. 3D printing is an additive process, using only the necessary amount of material. |

| Labor Costs | High. Multiple steps and skilled labor are required for machining, assembly, etc. | Relatively low. Once the 3D model is prepared, the printing process is mostly automated. |

For complex designs, traditional manufacturing may require additional steps or even multiple components to be assembled, increasing costs. In contrast, 3D printing can create complex geometries in one single print job, eliminating the need for additional assembly and reducing costs associated with joining multiple parts.

Design Flexibility

3D design offers unparalleled design flexibility. With traditional manufacturing methods, there are often limitations on the complexity of shapes that can be produced. For instance, creating an object with internal cavities or intricate lattice structures would be extremely difficult or even impossible with traditional machining.

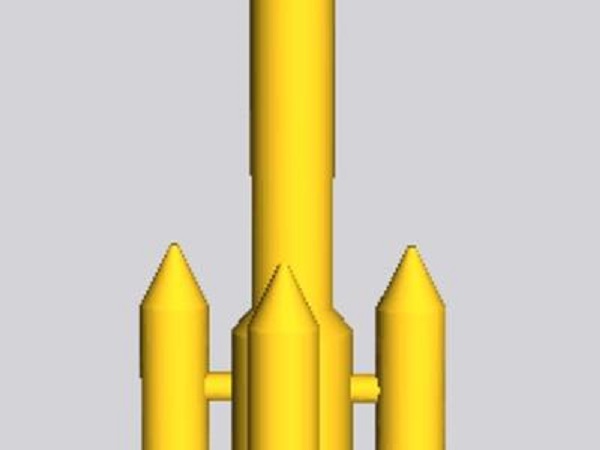

However, 3D design software allows designers to create highly complex and personalized designs. A famous example is the 3D - printed prosthetics. These can be custom - designed to fit the unique shape of a patient's limb, providing a more comfortable and functional solution. Another example is in the field of jewelry design. Designers can create one - of - a - kind pieces with elaborate patterns and interlocking elements that would be nearly impossible to achieve through traditional casting or carving methods. The freedom in 3D design truly unlocks a world of creative possibilities, enabling products that are not only functional but also aesthetically unique.

Yigu Technology's View on 3D Design and Printing Service

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values 3D design and printing service. In product development, 3D design allows our designers to quickly transform abstract ideas into detailed 3D models. This not only makes it easier for our clients to visualize the final product but also enables us to identify and address design flaws in the early stages.

When it comes to 3D printing, it provides us with a cost - effective solution for producing prototypes and small - batch products. For example, when developing a new non - standard plastic component, instead of spending a large amount of money on traditional mold - making, we can use 3D printing to quickly produce a sample for testing. This reduces the time and cost of the development cycle.

Moreover, the combination of 3D design and printing with our business also offers more customization options for our clients. We can create unique products that meet their specific requirements, whether it's in terms of shape, size, or functionality. In a nutshell, 3D design and printing service have become essential tools for Yigu Technology to enhance product development efficiency and meet the diverse needs of our customers.

FAQ

What types of materials can be used in 3D printing?

Common materials for 3D printing include plastics like PLA, ABS, and PETG. PLA, made from renewable resources such as corn starch, is easy to print, has a low melting point, and is environmentally friendly. It's often used for educational purposes and making simple models. ABS, on the other hand, has high strength and heat resistance, making it suitable for parts that need to withstand more stress, like functional prototypes in the automotive or electronics industries. PETG offers good transparency, low shrinkage, and is resistant to weather and chemicals, so it's great for creating clear enclosures or outdoor - use components.

Metals like stainless steel, titanium, and aluminum can also be 3D - printed. Stainless steel is popular for its strength and corrosion resistance, used in applications like manufacturing high - strength mechanical parts and medical devices. Titanium, being strong and lightweight with excellent biocompatibility, is widely used in aerospace and medical implants. Additionally, there are ceramic materials for high - temperature and wear - resistant applications, and even specialized materials like resin for high - precision, detailed prints in jewelry making or micro - scale models.

How accurate is 3D printing?

The accuracy of 3D printing can vary widely depending on several factors. For desktop FDM (Fused Deposition Modeling) 3D printers, which are more commonly used by hobbyists and small - scale users, the typical accuracy ranges from ±0.1mm to ±0.5mm. For example, a well - tuned mid - range FDM printer might have an accuracy of around ±0.2mm, meaning the final printed object could deviate from the original 3D model by up to 0.2mm in any dimension.

Industrial - grade 3D printers, especially those using technologies like SLA (Stereolithography) or SLM (Selective Laser Melting), can achieve much higher precision. SLA printers can reach accuracies as high as ±0.05mm or even better in some cases, making them ideal for creating very detailed and precise parts such as dental models or intricate jewelry pieces. SLM printers, used for metal 3D printing, can also offer high accuracy, with some models capable of achieving tolerances within ±0.1mm for metal components used in aerospace or high - end manufacturing. However, factors like the complexity of the model, material shrinkage during cooling, and the quality of the printer itself can all impact the final accuracy.

Can I use my own 3D design for 3D printing service?

Yes, you can use your own 3D design for 3D printing services. Most 3D printing service providers accept a variety of 3D file formats, such as STL (Standard Tessellation Language), OBJ (Object File Format), and 3MF (3D Manufacturing Format).

When submitting your own 3D design, there are several important things to note. First, ensure that your model is "watertight," meaning there are no holes or gaps in the geometry. This is crucial as 3D printers need a complete, closed - surface model to print accurately. You can use software tools like Netfabb or Meshmixer to check and repair any issues with your model's geometry. Second, consider the wall thickness of your design. Different 3D printing technologies and materials have minimum and recommended wall thickness requirements. For example, with FDM printing using PLA, a minimum wall thickness of around 1 - 2mm is often recommended to ensure structural integrity. Finally, if your design has overhangs or complex geometries, you may need to add support structures. Some 3D printing software can automatically generate these supports, but it's important to review and adjust them if necessary to ensure a successful print.