What is 3D Printing Bronze?

Definition and Basics

3D printing bronze, also known as bronze 3D printing, is an innovative manufacturing process that combines the art of 3D printing with the classic metal material - bronze. In traditional 3D printing, materials are typically plastics or resins. However, 3D printing bronze uses powdered bronze alloy as the raw material.

The process starts with a digital 3D model created using computer - aided design (CAD) software. This model is then sliced into thin layers by the 3D printing software. For bronze 3D printing, technologies like Selective Laser Sintering (SLS) are commonly used. In SLS, a high - power laser scans the powdered bronze according to the cross - sectional shape of each layer in the sliced model. The heat from the laser sinters (fuses) the bronze powder together, layer by layer, gradually building up the three - dimensional object.

Bronze Material Properties

Bronze is an alloy mainly composed of copper and tin, with some other elements sometimes added to enhance specific properties. It has a long - standing reputation for its remarkable characteristics, which make it an excellent choice for 3D printing in various applications.

- High Thermal Conductivity: Bronze has good thermal conductivity, which means it can efficiently transfer heat. For example, in applications where heat dissipation is crucial, such as in some high - performance electronic components or heat exchangers, 3D - printed bronze parts can help maintain optimal operating temperatures. This property allows the material to handle heat - related stress well, ensuring the longevity and reliability of the printed components.

- Good Electrical Conductivity: Similar to its thermal conductivity, bronze also exhibits decent electrical conductivity. This makes it suitable for 3D - printed electrical connectors, circuit components, and other applications in the electronics industry. The ability to conduct electricity effectively enables the creation of complex and precise electrical components through 3D printing, which can be customized according to specific design requirements.

- High Machinability: Bronze is relatively easy to machine. After 3D printing, if there are any post - processing requirements, such as drilling, milling, or polishing, bronze parts can be machined with relative ease. This is in contrast to some other materials that may be too brittle or hard to be machined effectively. Machinability allows for the final shaping and finishing of 3D - printed bronze objects to meet strict dimensional tolerances and surface quality standards.

- Exceptional Corrosion Resistance: Bronze has excellent corrosion resistance, especially when compared to many other metals. This property makes 3D - printed bronze parts suitable for outdoor applications, marine environments, or any situation where the component will be exposed to moisture, chemicals, or other corrosive agents. For instance, 3D - printed bronze sculptures can maintain their luster and structural integrity for years outdoors without significant degradation.

- High Strength and Durability: Bronze offers high strength and durability, making it ideal for manufacturing parts that need to withstand mechanical stress, wear, and tear. Whether it's for industrial machinery components, gears, or even some high - end consumer products, 3D - printed bronze can provide the necessary strength and long - term performance.

3D Printing Technologies for Bronze

There are several 3D printing technologies suitable for bronze, each with its own characteristics and applications.

Selective Laser Melting (SLM)

- Working Principle: SLM is a powder - bed fusion technology. A high - power laser is used as the heat source. First, a 3D model is created in CAD software and sliced into thin layers. Then, the laser scans the powdered bronze according to the cross - sectional shape of each layer. The intense heat from the laser fully melts the bronze powder, and as the layers are built up successively, a solid 3D object is formed. For example, in a typical SLM process, the laser beam with a power density of up to \(5\times10^{6}W/cm^{2}\) can quickly melt the bronze powder particles, fusing them together atomically.

- Advantages and Disadvantages:

- Advantages: It offers high precision, capable of achieving complex geometries with feature sizes down to the micron level. The material utilization rate is high, as the un - melted powder can be recycled, usually with a waste rate of less than 5%. The mechanical properties of the printed parts are excellent, often approaching or even surpassing those of conventionally manufactured parts. For instance, in the production of small, intricate bronze components for jewelry, the high precision of SLM can capture every fine detail.

- Disadvantages: The equipment cost is relatively high, including the purchase price of the SLM machine and its maintenance expenses. The printing speed is slow, especially for large - scale parts, which may limit its application in high - volume production scenarios. The surface roughness of the printed parts is relatively high, often requiring post - processing such as polishing to meet the required surface quality standards.

- Application Cases: In the aerospace industry, SLM - printed bronze components are used in some high - performance engine parts due to their high strength - to - weight ratio and excellent mechanical properties. For example, certain bronze alloy parts in satellite engines can be produced by SLM to reduce weight while maintaining high reliability. In the automotive manufacturing field, SLM - printed bronze parts are used in high - end sports cars for components like engine valves and transmission gears, where the high - precision and high - strength features of SLM - printed parts can improve the overall performance of the vehicle.

Selective Electron Beam Melting (SEBM)

- Working Principle: SEBM is also a powder - bed fusion technology. It creates a 3D model in the same way as SLM. However, instead of using a laser, it employs an electron beam as the heat source. The electron beam is deflected by electromagnetic coils to selectively melt the bronze powder layers, gradually building the 3D object. The process occurs in a high - vacuum environment.

- Differences and Similarities with SLM:

- Similarities: Both are powder - bed fusion technologies and can produce complex 3D metal parts layer - by - layer from a digital model.

- Differences: The heat source is different; SLM uses a laser, while SEBM uses an electron beam. SEBM operates in a high - vacuum environment, which can prevent oxidation during the melting process, while SLM usually operates in an inert gas environment.

- Advantages: The high - vacuum environment in SEBM effectively avoids oxidation of the bronze during the melting process, ensuring high - quality parts. It has a lower reflectivity issue compared to SLM when processing bronze, as the interaction between the electron beam and the powder is different from that of a laser. This makes it more suitable for processing high - reflectivity materials like bronze. For example, when printing large - scale bronze art sculptures, the high - vacuum and low - reflectivity advantages of SEBM can ensure better quality and less energy loss during the printing process. In most cases, post - heat treatment is not required because the SEBM forming process involves pre - heating the substrate, which helps to reduce internal stress in the printed parts.

Binder Jetting (BJ)

- Working Process: BJ starts with spreading a layer of bronze powder on the build platform. Instead of melting the powder directly, a print head sprays a liquid binder onto the powder in the shape of the cross - section of the part for that layer. The binder bonds the powder particles together. After each layer is printed, the build platform is lowered, a new layer of powder is spread, and the process repeats. Once the part is fully printed, it is removed from the powder bed and undergoes a sintering process in a high - temperature furnace. During sintering, the binder is burned off, and the bronze particles fuse together, densifying the part.

- Advantages: BJ is highly efficient and can be used for large - scale production. It is capable of manufacturing complex - shaped parts with ease, even parts with overhangs and internal cavities, without the need for complex support structures as in some other 3D printing methods. For example, in the production of large - scale bronze architectural decorations, BJ can quickly produce the required parts in large quantities. The equipment cost of BJ is relatively lower compared to SLM and SEBM, making it more accessible for some small - and medium - sized enterprises. Additionally, it allows for the use of a wider range of materials, as long as they can be made into powder form and have a suitable binder.

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology sees great potential in 3D printing bronze. In custom - made production, 3D printing bronze enables the creation of highly customized parts with complex geometries that are difficult to achieve through traditional manufacturing methods. This allows us to meet the unique requirements of our clients precisely.

However, we also face some challenges. The high cost of 3D printing equipment and bronze powder can increase production costs. Moreover, ensuring consistent quality in large - scale production is a hurdle. To address these, we are constantly exploring cost - effective printing technologies and optimizing material utilization. We also invest in quality control systems to guarantee the reliability of 3D - printed bronze products. By doing so, we aim to provide our clients with high - quality, customized 3D - printed bronze solutions at a reasonable cost.

FAQs about 3D Printing Bronze

What are the common 3D printing technologies for bronze?

- Selective Laser Melting (SLM): As mentioned before, it uses a high - power laser to fully melt bronze powder layer by layer. It offers high precision, with feature sizes down to the micron level, and high material utilization. For example, it can achieve a dimensional accuracy of ±0.05mm for small - sized parts.

- Selective Electron Beam Melting (SEBM): Employs an electron beam as the heat source in a high - vacuum environment. It has the advantage of preventing oxidation during melting and has a lower reflectivity issue when dealing with bronze compared to SLM.

- Binder Jetting (BJ): Sprays a liquid binder onto bronze powder layers. It is highly efficient for large - scale production, can create complex - shaped parts easily, and has a relatively low equipment cost.

How to choose the right 3D printing technology for bronze?

- Consider Part Complexity: For parts with extremely complex geometries and high - precision requirements, such as small, intricate jewelry components or some aerospace parts with complex internal channels, SLM is a good choice. If the part has large - scale complex shapes like large - scale art sculptures, SEBM or BJ can be considered. BJ can handle complex shapes well for large - scale production, while SEBM can ensure quality in a high - vacuum environment during the printing of large parts.

- Think about Production Scale: For small - batch production of high - value parts, SLM or SEBM can be used. When it comes to large - volume production, BJ is more suitable due to its high - efficiency and cost - effective characteristics. For example, if you need to produce 100 high - end bronze engine valves for a luxury car model, SLM might be appropriate; but if you need to produce 10,000 bronze architectural decorations, BJ would be a better option.

- Evaluate Cost: SLM and SEBM have high equipment costs, and the operation and maintenance costs are also relatively high. BJ has a lower equipment cost. If cost is a major concern and the part does not require extremely high precision, BJ can be a preferred choice. However, if the quality and performance of the parts are crucial and cost is not the most restrictive factor, SLM or SEBM may still be considered for their superior mechanical properties and precision.

What are the main applications of 3D printed bronze parts?

- Aerospace: In the aerospace industry, 3D - printed bronze parts are used in engine components. For example, bronze alloy parts in some satellite engines can be produced by 3D printing to reduce weight while maintaining high strength and reliability. The high - strength and heat - resistant properties of bronze make it suitable for parts that need to withstand high - temperature and high - stress environments in aerospace applications.

- Automotive: In the automotive field, 3D - printed bronze parts are applied to engine valves, transmission gears, and other components. The high - precision and high - strength features of 3D - printed parts can improve the overall performance of the vehicle. For high - end sports cars, the use of 3D - printed bronze parts can enhance engine efficiency and transmission smoothness.

- Electronics: Due to its good electrical conductivity, 3D - printed bronze is used in electrical connectors and circuit components. For example, in some high - performance electronic devices, bronze connectors printed by 3D technology can ensure stable electrical connection and efficient signal transmission.

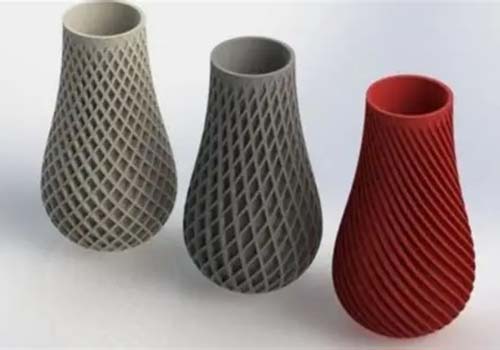

- Art and Design: 3D - printed bronze is widely used in creating art sculptures and high - end jewelry. The ability to create complex and detailed shapes through 3D printing allows artists and designers to bring their creative ideas to life. For instance, unique bronze artworks with intricate patterns can be produced, and in the jewelry industry, custom - designed bronze jewelry with fine details can be made.