1. The Basics of 3D Printing

1.1 What is 3D Printing?

3D printing, also known as additive manufacturing, is a revolutionary technology that constructs three - dimensional solid objects from a digital file. Instead of subtracting material like traditional manufacturing methods (such as cutting, milling), 3D printing builds objects layer by layer. It uses powdery metal, plastic, or other adhesive materials as the building blocks. For example, in a typical 3D printing process for creating a small plastic figurine, the printer takes instructions from a digital model file and deposits thin layers of melted plastic one on top of another until the entire figurine is formed. This technology has opened up new possibilities for product design, prototyping, and manufacturing, allowing for the creation of complex geometries that were previously difficult or impossible to achieve with traditional techniques.

1.2 How Does 3D Printing Work?

Three key elements are required for 3D printing: a digital file, a 3D printer, and materials.

- Digital File: This is the blueprint for the object to be printed. It is usually created using computer - aided design (CAD) software or obtained from a 3D scanner. The digital file contains all the geometric information about the object, including its shape, size, and internal structure.

- 3D Printer: The printer is the device that brings the digital model to life. It reads the digital file and precisely deposits the material layer by layer according to the instructions.

- Materials: There is a wide range of materials available for 3D printing. Common ones include metals (such as aluminum, titanium), nylon, glass fiber, PLA (polylactic acid, a biodegradable thermoplastic), resin, and rubber. For instance, PLA is popular among hobbyists and small - scale manufacturers because it is easy to print with, has a relatively low melting point, and is environmentally friendly.

There are several mainstream 3D printing technologies, each with its own working principle:

- FDM (Fused Deposition Modeling): In FDM, a filament of thermoplastic material (like ABS or PLA) is fed into a heated extruder nozzle. The material is melted and then extruded layer by layer onto a build platform. As the layers cool, they solidify and bond together to form the final object. FDM printers are relatively affordable and widely used for home and small - scale production. For example, many DIY enthusiasts use FDM printers to create custom - made phone cases, small toys, and prototypes.

- SLA (Stereolithography Apparatus): SLA uses a laser to cure layers of liquid photopolymer resin. The laser traces the cross - section of the object onto the surface of the resin, solidifying it. Each layer is cured one after another, and the build platform gradually lowers as the object is being built. SLA is known for its high - resolution prints and is often used in jewelry making, dental applications, and the production of detailed models.

- 3DP (Three Dimensional Printing and Gluing): This technology starts by spreading a layer of powder (such as ceramic, metal, or plastic powder). Then, a nozzle sprays an adhesive in the areas where the powder needs to be bonded together to form the cross - section of the object. This process is repeated layer by layer until the object is complete. 3DP is capable of producing objects with complex internal structures and can also create full - color prints in some cases.

- SLS (Selective Laser Sintering): SLS uses a laser to sinter powdered material. The laser heats the powder particles, causing them to fuse together. The process is carried out in a powder bed, and as each layer is sintered, a new layer of powder is spread on top. SLS is suitable for producing functional parts with high strength, such as components for the automotive and aerospace industries. However, it is a more complex and expensive technology compared to some others.

2. The Significance of Terraforming Mars

2.1 Reasons for Terraforming Mars

The Earth, our current home, is facing a series of serious challenges. The global population is booming. According to the United Nations, the world population is expected to reach 9.7 billion by 2050 and could exceed 10 billion by the end of the century. This rapid growth has led to an increasing demand for resources. For example, the demand for fresh water is soaring. Currently, about 2.2 billion people worldwide lack access to safe drinking water, and this number is projected to rise as the population grows. The shortage of food is also a severe issue. By 2050, global food production needs to increase by 60% to meet the demand of the growing population.

In addition, the over - exploitation of non - renewable resources such as fossil fuels is depleting these resources at an alarming rate. It is estimated that at the current rate of consumption, oil reserves may only last for about 50 more years, and natural gas for around 60 years. Moreover, environmental problems like climate change, caused mainly by the excessive emission of greenhouse gases from the use of fossil fuels, are making the Earth less habitable in some regions. Rising sea levels threaten coastal areas, extreme weather events such as hurricanes, droughts, and floods are becoming more frequent and intense.

Mars, with its relatively close proximity to Earth in the solar system, becomes an attractive option for human expansion. Terraforming Mars could potentially create a new living space for humanity, alleviating the pressure on Earth's resources and population. It offers the possibility of a backup plan for the human race in case of a global catastrophe on Earth, such as a large - scale asteroid impact, a super - volcanic eruption, or a global pandemic that could threaten the survival of the entire species.

2.2 Current Progress in Terraforming Mars Research

Scientists have made some promising progress in terraforming Mars research.

- Atmospheric Modification: One of the key aspects is to thicken the Martian atmosphere. Currently, the Martian atmosphere is mainly composed of carbon dioxide and is extremely thin, with a surface pressure less than 1% of Earth's. Some proposed methods include releasing greenhouse gases on Mars. A recent study by a team of scientists suggested using local resources on Mars to produce and release greenhouse gases. For example, by mining and processing Martian regolith (the loose surface material on Mars), certain compounds could be released to enhance the greenhouse effect, gradually warming the planet.

- Temperature Increase: Mars has an average surface temperature of about - 63°C. To make it more habitable, raising the temperature is crucial. Scientists have proposed using large - scale mirrors in space to reflect more sunlight onto the Martian surface, especially on the polar ice caps. This would melt the ice, releasing trapped carbon dioxide and further contributing to the greenhouse effect, thus increasing the temperature.

- Water Resource Exploration: Water is essential for life. Recent Mars exploration missions, such as NASA's Mars Reconnaissance Orbiter and the Chinese Tianwen - 1 mission, have provided strong evidence of the existence of water on Mars. There are large amounts of water ice at the poles, and some regions may also have underground water reserves. Understanding the distribution and accessibility of these water resources is a significant step towards making Mars habitable. Scientists are also researching methods to extract and purify this water for human use, agriculture, and industrial processes.

3. The Intersection of 3D Printing and Terraforming Mars

3.1 Construction on Mars with 3D Printing

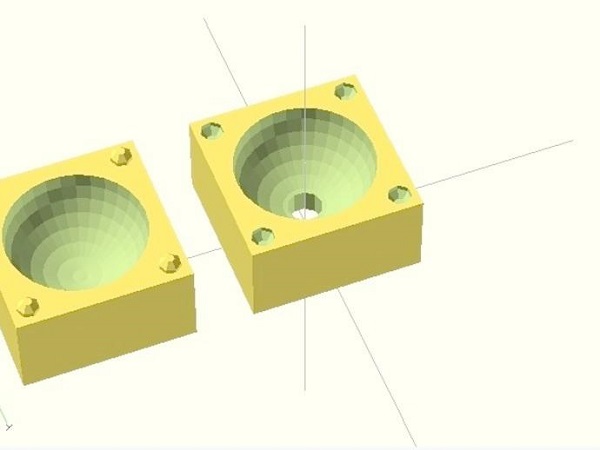

3D printing holds great promise for construction on Mars. One of the most significant applications is in building habitats for astronauts. Scientists envision using Martian soil, also known as regolith, as the raw material for 3D printing. A study by NASA has shown that by mixing Martian regolith with a binding agent, it is possible to create a printable material. This material can then be used to print the walls, floors, and other structural components of a habitat.

Compared to traditional construction methods, 3D printing offers several advantages. Firstly, it reduces the need to transport large amounts of building materials from Earth to Mars. The cost of transporting materials to Mars is extremely high, with estimates ranging from \(10,000 to \)100,000 per pound. By using local materials on Mars, this cost can be significantly reduced. Secondly, 3D printing allows for the creation of complex and optimized structures. Traditional construction methods are often limited by the shapes and sizes of pre - fabricated components. In contrast, 3D printing can create structures with intricate geometries, such as curved walls and domed ceilings, which can better withstand the harsh Martian environment, including high - speed winds and meteorite impacts. For example, a 3D - printed dome - shaped habitat could distribute stress more evenly, making it more durable than a traditional rectangular - shaped building.

3.2 Manufacturing Tools and Equipment

In addition to construction, 3D printing can be used to manufacture tools and equipment on Mars. During long - term Mars missions, tools may break or new equipment may be needed. Instead of relying on Earth - based supplies, astronauts could use 3D printers to produce the necessary items on - site.

A wide range of tools and equipment can be printed. Simple hand tools like wrenches, screwdrivers, and pliers can be easily printed using 3D printers. For more complex equipment, components can be printed and then assembled. For instance, parts of a rover, such as wheels, brackets, and even some electrical components, could be printed. This not only saves the cost and time of transporting these items from Earth but also provides a quick solution when repairs are needed. A study by the European Space Agency (ESA) has demonstrated the feasibility of 3D - printing metal components for space - related applications. By using Martian resources or materials brought from Earth in a more efficient way, the mission's self - sufficiency can be greatly enhanced.

3.3 Creating Life - Support Systems Components

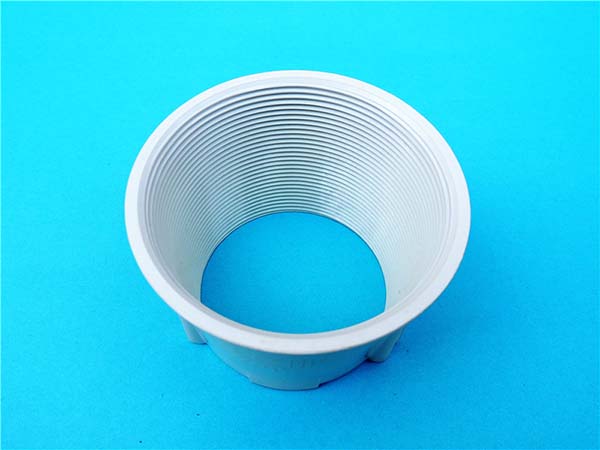

Life - support systems are crucial for the survival of astronauts on Mars, and 3D printing can play a vital role in manufacturing their components. Components such as air - filtering devices and water - recycling equipment are essential parts of the life - support system.

Air - filtering devices are needed to purify the Martian air, which is mainly composed of carbon dioxide with small amounts of other gases. 3D printing can be used to create complex filter structures with high - efficiency filtration capabilities. These filters can be designed to remove harmful particles and adjust the gas composition to make the air breathable for astronauts.

Water - recycling equipment is also a key component. Water is a scarce resource on Mars, and recycling is essential. 3D - printed water - recycling equipment can be customized to fit the specific needs of a Mars mission. For example, it can be designed to efficiently extract and purify water from sources such as Martian ice or the small amounts of water vapor in the atmosphere. A research project at a leading aerospace research institute has successfully 3D - printed a prototype of a water - recycling component, demonstrating the potential of this technology in supporting long - term human presence on Mars.

4. Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology recognizes the unique advantages that 3D printing brings to Mars - related projects. The technology's ability to create complex structures with local materials on Mars is a game - changer. Yigu Technology has the expertise to provide customized materials and components for 3D printing in the context of Mars missions. For example, we can develop special plastic - metal composite materials that are more suitable for the harsh Martian environment, such as materials with high - temperature resistance, strong radiation resistance, and excellent mechanical properties.

In the future, Yigu Technology is eager to participate in the research and development cooperation of 3D printing for terraforming Mars. We believe that our rich experience in custom - made products and in - depth understanding of material properties can contribute to the development of more advanced 3D printing solutions for Mars, helping to make the dream of terraforming Mars a reality faster.

5. FAQs

5.1 What are the main materials that can be used for 3D printing on Mars?

On Mars, the main materials for 3D printing include Martian soil, also known as regolith. Studies have shown that by adding a binding agent to Martian regolith, it can be made into a printable material. For example, a research project demonstrated that with the right binder, Martian regolith could be used to print the structural components of habitats. Besides, materials brought from Earth can also be used, such as metals like aluminum and titanium, which are strong and lightweight, suitable for manufacturing tools and equipment parts. Plastics like PLA can also be used for 3D printing on Mars, especially for creating small - scale objects or components that require certain flexibility and corrosion - resistance.

5.2 How accurate can 3D printing be in the low - gravity environment of Mars?

The low - gravity environment on Mars does have an impact on 3D printing accuracy. In low - gravity conditions, the flow and deposition of materials may be different from those on Earth. For instance, when using FDM technology, the extrusion and layering of the molten material might be affected, potentially leading to uneven layers. However, scientists are working on solutions. Some proposed methods include using magnetic or electrostatic fields to better control the movement and deposition of materials. Current research indicates that with proper adjustments and new control mechanisms, 3D printing on Mars can achieve an accuracy comparable to that on Earth in many cases, with dimensional accuracies within a few millimeters for small - scale objects, which is sufficient for most basic construction and tool - making needs on Mars.

5.3 Can 3D printing completely replace traditional manufacturing methods in terraforming Mars?

3D printing cannot completely replace traditional manufacturing methods in terraforming Mars. 3D printing has its own advantages, such as high customization, low material waste, and the ability to use local resources. It can quickly create complex - shaped components and structures on - site. However, traditional manufacturing methods also have their merits. For large - scale production of simple and standardized parts, traditional manufacturing methods like injection molding (if the equipment and materials are available) can be more efficient in terms of production speed. Traditional machining methods can also achieve very high precision for certain high - tolerance parts. In terraforming Mars, a combination of 3D printing and traditional manufacturing methods is more likely to be used. For example, 3D printing can be used for creating custom - made parts for life - support systems, while traditional manufacturing methods can be employed for mass - producing basic structural components like large - scale metal beams for building frameworks.