What is an Acrylic Prototype?

An acrylic prototype is a preliminary model of a product crafted from acrylic material, which serves as a vital tool in the product design and development process. Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic renowned for its excellent optical clarity, high strength - to - weight ratio, and weather resistance.

The Role in Product Development

- Visualization: In the early stages of product design, an acrylic prototype allows designers and clients to visualize the final product in three - dimensional form. For example, when developing a new smartphone case, an acrylic prototype can accurately represent the shape, size, and curvature of the case, enabling stakeholders to assess its aesthetic appeal and ergonomics. This is far more effective than just looking at 2D sketches or CAD (Computer - Aided Design) renderings on a screen.

- Function Testing: It can be used to test the functionality of a product concept. Suppose a company is designing a new type of dispenser. An acrylic prototype can be built to test the flow rate of the liquid, the ease of operation of the dispensing mechanism, and the stability of the overall structure. This helps in identifying design flaws early on, saving both time and money in the long - run.

Comparison with Other Prototype Materials

| Material | Cost | Strength | Transparency | Machinability |

| Acrylic | Moderate | High for its weight | Excellent (up to 92% light transmission) | Good, can be easily cut, drilled, and polished |

| Wood | Low - Moderate | Varies | Not transparent | Good for basic shaping, but may splinter |

| Metal | High | High | Opaque | Requires specialized tools for complex shapes |

| ABS Plastic | Low - Moderate | Moderate | Translucent to opaque | Fairly easy to work with, but may have surface roughness |

As shown in the table, acrylic stands out for its combination of good mechanical properties and high transparency, making it an ideal choice for prototypes where visual inspection and some level of mechanical strength are required.

Applications of Acrylic Prototypes

In the Electronics Industry

Acrylic prototypes play a significant role in the electronics industry. For instance, they are widely used in manufacturing the outer casings of various electronic devices. The high transparency of acrylic allows for the design of see - through cases, which can be both functional (showcasing internal components for diagnostic or aesthetic purposes) and visually appealing. In smartphones, acrylic prototypes can be used to test the fit and finish of the casing, ensuring that all ports, buttons, and camera cutouts are in the correct position.

Moreover, acrylic is an excellent material for creating display protectors. Its scratch - resistance and optical clarity make it suitable for safeguarding the screens of tablets, laptops, and monitors. In fact, some high - end display protectors are made from acrylic - based materials that can block harmful UV rays while maintaining the screen's high - definition visual experience.

In the Automotive Industry

In the automotive sector, acrylic prototypes are crucial for interior design development. Car manufacturers often use acrylic to create mock - ups of dashboards, center consoles, and door panels. This enables them to test the ergonomics, such as the reachability of controls and the comfort of the driver's and passengers' interaction with the interior components.

When it comes to headlights and taillights, acrylic prototypes are used to perfect the lens design. The material's ability to be molded into complex shapes and its high light - transmission properties make it ideal for this application. A well - designed acrylic lens can improve the efficiency of the lighting system, providing better illumination on the road while also enhancing the vehicle's aesthetic appearance.

In the Medical Field

In the medical field, acrylic prototypes are indispensable. They are used to create models of complex medical devices. For example, in the development of surgical instruments, acrylic prototypes allow surgeons and designers to test the functionality and usability of the instruments before mass production. This can help in reducing the risk of errors during actual surgeries.

Acrylic is also used in prosthetics design. By creating acrylic prototypes of prosthetic limbs, designers can adjust the shape, size, and fit to better suit the patient's needs. The lightweight nature of acrylic makes it a suitable material for prosthetics, reducing the burden on the patient while also providing enough strength for daily use. Additionally, the transparency of acrylic can be beneficial in some medical imaging applications, allowing for better visualization of internal structures when combined with appropriate imaging techniques.

How to Create an Acrylic Prototype?

Design Phase

The design phase is the cornerstone of creating an acrylic prototype. Using CAD (Computer - Aided Design) software is essential for precise design work. CAD software allows designers to create highly detailed 2D and 3D models of the prototype. For example, SolidWorks and AutoCAD are popular CAD software in the industry. With these tools, designers can accurately define the dimensions, shapes, and internal structures of the acrylic prototype. They can also perform simulations to check for potential design flaws, such as stress points in a mechanical part or improper fit between components. By making adjustments in the virtual environment, the chances of errors during the actual manufacturing process are significantly reduced.

Material Selection

There are different types of acrylic materials, each with its own characteristics and suitable application scenarios.

- General - purpose acrylic: This is the most commonly used type. It offers good optical clarity, with a light transmission rate of up to 92%, and is relatively easy to machine. It is suitable for a wide range of applications, such as display cases, signage, and simple product prototypes. For instance, a small - scale art exhibition might use general - purpose acrylic to create display stands for artworks due to its cost - effectiveness and good appearance.

- Impact - resistant acrylic: As the name implies, this type has enhanced impact resistance. It contains additives that improve its toughness, making it suitable for applications where the prototype may be subject to physical stress, like in automotive interior components or industrial equipment covers. In a car's interior, impact - resistant acrylic can be used to make the housing for some control panels, protecting the internal components from potential knocks.

- UV - stabilized acrylic: This acrylic is designed to resist the degradation caused by ultraviolet (UV) light. It is ideal for outdoor applications, such as outdoor signage or the lenses of solar - powered devices. Outdoor advertising signs made from UV - stabilized acrylic can maintain their color and clarity even after long - term exposure to sunlight.

Manufacturing Process

Several common manufacturing processes are used to create acrylic prototypes:

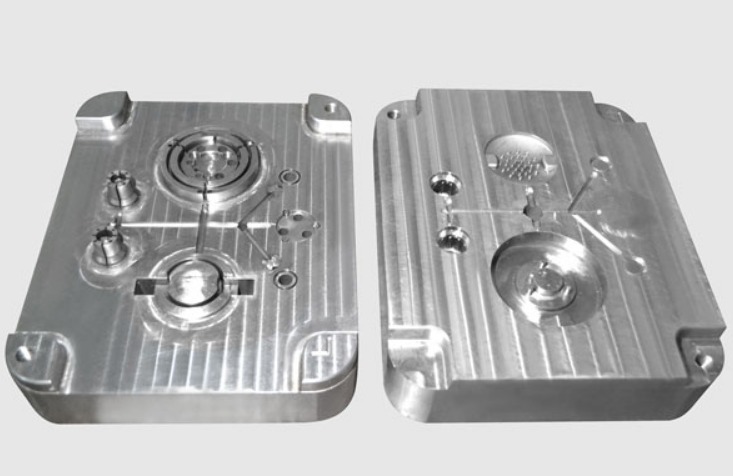

- CNC (Computer Numerical Control) machining: This process involves using computer - controlled machines to precisely cut, drill, and mill the acrylic material. CNC machining can achieve high precision, with tolerances as low as ±0.05 mm in some cases. It is suitable for creating prototypes with complex shapes and accurate dimensions. For example, when making a prototype of a custom - designed electronic device housing, CNC machining can create the precise cutouts for buttons, ports, and other components.

- 3D printing: In recent years, 3D printing has become an increasingly popular method for creating acrylic prototypes. Fused Deposition Modeling (FDM) and Stereolithography (SLA) are two common 3D - printing techniques used for acrylic. FDM 3D printers extrude molten acrylic filament layer by layer to build the prototype, while SLA uses a laser to cure liquid acrylic resin. 3D printing is advantageous for its ability to quickly create complex geometries without the need for extensive tooling. For example, a startup developing a unique - shaped medical device can use 3D printing to rapidly produce a functional prototype for initial testing.

- Laser cutting: Laser cutting is a process that uses a high - power laser to cut the acrylic material. It can create intricate shapes and patterns with high precision. Laser - cut edges are often smooth, reducing the need for extensive post - processing. This method is suitable for creating flat - shaped acrylic prototypes or parts that require precise cutouts, such as stencils or decorative panels. A jewelry designer might use laser cutting to create a prototype of an acrylic pendant with detailed patterns.

Yigu Technology's View

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values the role of acrylic prototypes. In our custom services, acrylic prototypes are frequently used due to their versatility. The excellent transparency of acrylic allows us to create prototypes for products that require visual inspection, such as display - related items. For example, when custom - making a unique display stand for a client, an acrylic prototype can quickly show the final look and functionality.

The cost - effectiveness and ease of machining of acrylic also make it an attractive option. We can efficiently produce prototypes with complex shapes using techniques like CNC machining or laser cutting, which are part of our service offerings. This helps our clients to test their product ideas without high costs. In addition, the wide range of available acrylic types enables us to meet different requirements from clients, whether it's impact - resistance for industrial products or UV - stability for outdoor - use items.

FAQ

What is the typical turnaround time for creating an acrylic prototype?

The typical turnaround time for creating an acrylic prototype can vary depending on several factors. For a relatively simple acrylic prototype made through processes like laser cutting, it might take as little as 1 - 3 business days. This is because laser cutting is a fast process for flat - shaped designs. However, if the prototype is complex and requires CNC machining, especially when multiple operations such as milling, drilling, and polishing are involved, the turnaround time could be 5 - 7 business days. 3D printing an acrylic prototype also depends on the complexity of the model and the type of 3D - printing technology used. FDM 3D printing might be faster for simple geometries, usually within 2 - 4 days, while SLA, which can offer higher precision for more intricate parts, could take 3 - 6 days. Rush orders can sometimes be accommodated, but this often incurs additional costs.

Can I request custom colors for my acrylic prototype?

Yes, you can request custom colors for your acrylic prototype. Acrylic sheets are available in a wide range of standard colors, including clear, black, white, and various primary and secondary colors. If you need a non - standard color, there are two common ways to achieve this. One is by using colored acrylic pigments or dyes during the manufacturing of the acrylic material. This method ensures that the color is consistent throughout the prototype. Another option is to apply a custom - colored coating or paint to the surface of the acrylic prototype after it has been fabricated. However, when choosing the coating method, it's important to ensure that the paint or coating adheres well to the acrylic surface to avoid peeling or discoloration over time.