Introduction to CNC Manufacturing

Definition and History

Computer Numerical Control (CNC) manufacturing is a process where machines are controlled by pre-programmed computer software to perform precise operations like cutting, drilling, milling, and turning. The advent of CNC technology has transformed the manufacturing industry, enabling high precision, repeatability, and efficiency in producing parts and components across various industries.

The concept of CNC began in the 1940s with the development of numerical control (NC) systems, where punched tapes were used to control machine tools. However, it wasn’t until the 1970s, with the integration of computers into NC systems, that CNC became widely practical. Over the decades, CNC has evolved significantly, incorporating sophisticated software, automation, and high-speed operations that have made it indispensable in modern manufacturing.

Advantages Over Traditional Machining

CNC manufacturing offers several advantages over traditional manual machining methods:

- Precision and Accuracy: CNC machines are capable of producing parts with extremely tight tolerances and high repeatability, often down to microns.

- Efficiency: CNC machines operate automatically, reducing the risk of human error, increasing production speed, and optimizing material usage.

- Complexity: CNC allows for the creation of intricate, detailed designs that would be extremely difficult or impossible with manual methods.

- Consistency: Once programmed, CNC machines can produce identical parts with the same accuracy, ensuring consistency in large production runs.

- Cost-Effectiveness: Although the initial setup cost can be high, the efficiency, reduced labor costs, and high throughput of CNC systems offer long-term cost savings.

Applications of CNC in Industry

Automotive Sector

CNC manufacturing is essential in the automotive industry, where precision and reliability are critical. CNC machines are used to produce a wide range of components, including engine parts, transmission systems, brake systems, and body panels. These parts must meet exact specifications for performance, safety, and durability. Additionally, CNC technology enables rapid prototyping, which allows automotive manufacturers to test and iterate designs quickly before full-scale production.

Aerospace Industry

In aerospace manufacturing, CNC plays a crucial role in the production of components such as turbine blades, landing gear, aircraft body structures, and engines. The industry demands the highest levels of precision and performance, given the critical nature of its products. CNC technology helps meet stringent aerospace standards, creating lightweight yet durable components from materials like titanium, aluminum, and advanced composites. This ensures optimal fuel efficiency and structural integrity, which are vital for aircraft performance and safety.

Medical Device Manufacturing

CNC manufacturing is indispensable in the medical field, where the need for high precision and reliability is paramount. CNC machines are used to manufacture surgical instruments, prosthetics, implants, and orthopedic devices. These components require extreme accuracy, as even slight deviations can have serious implications for patient safety and device effectiveness. CNC also enables the production of customized medical devices, such as tailored implants, which are made to fit an individual patient's needs. The ability to handle biocompatible materials further expands the potential of CNC in medical manufacturing.

Types of CNC Machines

CNC Lathes

CNC lathes are used for turning operations, where the workpiece is rotated against a cutting tool to shape it. This type of machine is ideal for creating cylindrical parts such as shafts, spindles, and bushings. CNC lathes are known for their high precision and efficiency, making them a common choice for mass production of uniform parts.

CNC Mills

CNC milling machines use rotating cutters to remove material from a stationary workpiece. They can perform a variety of operations, including drilling, boring, cutting slots, and threading. CNC mills are capable of producing complex, three-dimensional shapes, making them versatile tools widely used in the automotive, aerospace, and electronics industries.

CNC Routers

CNC routers are similar to milling machines but are specifically designed for working with wood, plastics, composites, and other non-metallic materials. They are used in industries such as sign-making, woodworking, and model-making. CNC routers can perform intricate cuts, engravings, and carvings, making them ideal for both industrial and artisan applications.

CNC Machining Process

Programming and Setup

The CNC machining process starts with programming, which involves creating a 3D CAD model of the part. The design is then converted into G-code—a set of instructions that guide the machine’s movements and operations. This programming is critical because it determines the accuracy and efficiency of the final product. Once the program is ready, the machine is set up by loading the workpiece, securing it in place, and installing the necessary tools.

Material Selection

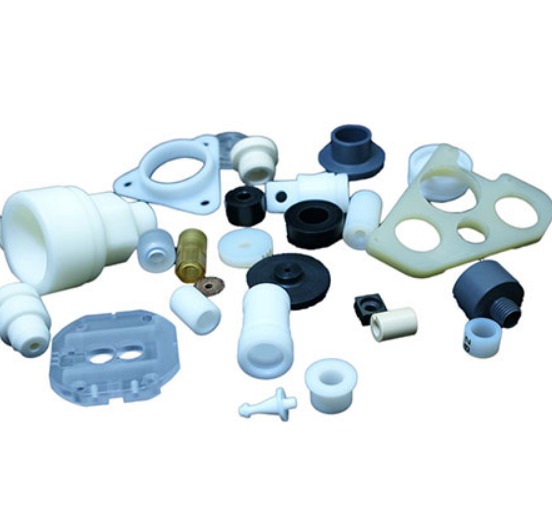

Choosing the appropriate material is key to achieving optimal performance. The selection depends on factors such as the part's mechanical properties, environmental resistance, and cost. Common materials used in CNC machining include:

- Metals: Aluminum, steel, titanium, copper.

- Plastics: ABS, polycarbonate, nylon.

- Composites: Carbon fiber, fiberglass.

Engineers must choose materials based on the part’s intended use and the machine's capabilities.

Machining Operations

Once setup is complete, the CNC machine begins its operations based on the programmed G-code. The machine removes excess material from the workpiece to shape it into the desired form. Depending on the complexity of the part, multiple machining operations may be required. After machining, parts may undergo post-processing such as deburring, polishing, heat treatment, or coating to improve their functionality, appearance, and durability.

Future Trends in CNC Technology

Automation and Robotics

The future of CNC manufacturing is increasingly tied to automation and robotics. Robotic arms can handle tasks such as loading and unloading materials, changing tools, and inspecting parts. These robots can work autonomously, reducing labor costs and minimizing human error. The integration of AI-powered robotics will further enhance the capabilities of CNC machines, making them smarter and more efficient.

Smart Factories

The rise of smart factories is transforming CNC manufacturing. These factories use Internet of Things (IoT) technologies to connect machines, sensors, and production systems in real-time. The data generated by CNC machines and other equipment can be analyzed to predict machine failures, optimize production schedules, and improve overall quality control. This connectivity allows manufacturers to implement predictive maintenance and continuously improve their processes.

Sustainable Manufacturing Practices

With sustainability becoming a priority for industries worldwide, CNC manufacturing is evolving to be more environmentally friendly. Key sustainable practices include:

- Reducing material waste through more precise cutting and efficient use of raw materials.

- Recycling scrap material and using eco-friendly lubricants.

- Energy-efficient CNC machines that lower power consumption.

- Eco-friendly cooling systems that minimize harmful emissions and reduce environmental impact.

CNC manufacturing can help industries meet their sustainability goals by adopting these eco-conscious approaches, playing a pivotal role in greener manufacturing.

FAQs

What makes CNC manufacturing superior to traditional methods?

CNC manufacturing offers unmatched precision, repeatability, and efficiency. Unlike traditional methods, CNC machines are capable of producing parts with extremely tight tolerances and can easily handle complex designs. The process is automated, which minimizes human error and speeds up production. Additionally, CNC technology allows for rapid prototyping, making it easier to test and iterate designs.

How does CNC technology benefit small businesses?

CNC technology enables small businesses to produce high-quality parts without needing a large workforce or significant infrastructure. It levels the playing field by giving small firms access to advanced manufacturing capabilities typically available to larger companies. CNC systems also make it easier to scale production and customize products to meet specific customer demands, all while keeping costs down.

Are there any limitations to using CNC machines?

While CNC machines are incredibly powerful, they do have some limitations:

- Initial investment: CNC machines can be expensive, especially for high-precision models.

- Skill requirements: Operating CNC machines requires specialized knowledge and training, which may be a barrier for small businesses without skilled personnel.

- Maintenance: Regular maintenance is necessary to keep machines running efficiently. Neglecting maintenance can lead to downtime and costly repairs.

Despite these challenges, the benefits of CNC manufacturing typically outweigh the limitations, especially with careful planning and investment.

Conclusion

CNC manufacturing has revolutionized modern industry, offering unparalleled precision, efficiency, and versatility across sectors like automotive, aerospace, and medical device production. As technology advances, CNC systems will continue to evolve, integrating automation, smart technologies, and sustainability practices that will define the future of manufacturing.