Anyone who’s stared at a CNC machine screen, watching a tool carve the wrong path because of a misplaced G-code, knows the frustration. A single mistyped digit in a G01 command can ruin hours of work on an automotive part, while incorrect feed rates might leave a rough surface finish on a critical aerospace component. These aren’t just minor errors—they cost shops an average of $2,000 per mishap, according to a 2024 survey of manufacturing professionals. Whether you’re struggling with circular interpolation for complex curves or debugging a subprogram loop, G codes machining can feel like navigating a maze without a map. In this guide, we’ll break down everything from G-code basics to advanced programming techniques, helping you avoid common pitfalls and achieve consistent precision.

G-Code Basics: The Language of CNC Machines

At its core, G-code is the numerical language that tells CNC machines what to do. Understanding its fundamentals is the first step to error-free programming:

- G-code syntax: Commands follow a simple structure—G (for preparatory function) + a number (e.g., G00 for rapid positioning) + parameters (like X, Y, Z coordinates). A typical line might look like: G01 X10.5 Y5.2 F200, where F sets the feed rate.

- Coordinate systems: Most programs use G54 (work offset) to set the part’s origin, though G55-G59 offer additional offsets. A study by the Manufacturing Technology Association found that 60% of programming errors stem from incorrect coordinate setup.

- Tool paths: Linear interpolation (G01) moves tools in straight lines, while circular interpolation (G02/G03) creates arcs. For example, G02 X20 Y15 I2 J0 draws a clockwise arc from the current position to X20 Y15, using I and J to define the arc center.

Mastering these basics reduces programming time by up to 40%, according to veteran CNC programmers. Even experienced users benefit from double-checking command structure—a missing decimal point in a coordinate can turn a 10mm move into a 1000mm disaster.

Machining Operations: Matching G-Codes to the Task

Different machining tasks require specific G-codes to achieve optimal results:

- Milling: G04 (dwell) pauses the tool to let chips clear, crucial for deep pocketing. G17 selects the XY plane, while G18/G19 switch to XZ/YZ for angled cuts.

- Turning: G71 (roughing cycle) removes large amounts of material quickly, saving up to 50% of cycle time compared to manual G01 steps. G70 (finishing cycle) follows to achieve tight tolerances.

- Drilling: G81 is basic peck drilling, but G83 (deep hole drilling) retracts the tool periodically to break chips—essential for holes deeper than 3x diameter in steel.

- Engraving: G01 with high spindle speeds (up to 10,000 RPM) and low feed rates (50-100 mm/min) creates crisp text, though G00 rapid moves must be programmed carefully to avoid gouging.

A recent case study showed a medical parts manufacturer reduced scrap rates by 35% after standardizing G-code templates for common operations like contouring and grinding.

Programming Techniques: From Manual to CAD/CAM

Choosing the right programming method depends on part complexity:

- Manual programming: Best for simple parts, like a 2D bracket with a few holes. A skilled programmer can write 100 lines of code in under an hour, but errors increase with length.

- CAD/CAM software: Tools like Mastercam or Fusion 360 automate code generation for complex parts. One aerospace supplier reported a 70% faster turnaround on turbine blades after switching from manual programming to CAD/CAM.

- Subprograms: G65 (macro call) lets you reuse code blocks, reducing file size by 60% for parts with repeated features, like a gear with 20 teeth.

- Tool compensation: G41/G42 adjusts for tool radius, critical for contouring to maintain dimensional accuracy. A 0.1mm tool radius error can lead to a 0.2mm part deviation.

The table below compares key techniques:

| Technique | Best For | Error Rate* | Time Savings |

| Manual Programming | Simple 2D parts | 8-12% | N/A |

| CAD/CAM | Complex 3D parts | 1-3% | 50-80% |

| Subprograms | Parts with repeated features | 2-5% | 30-50% |

*Based on industry average for 500-line programs

Machining Equipment: G-Code Compatibility Across Machines

Not all machines interpret G-codes the same way—knowing your equipment is key:

- CNC mills: Most support G00-G99, but 5-axis machines add G17-G19 for plane selection. Haas mills, for example, use G28 for reference point return, while Fanuc uses G30.

- Lathes: Special codes like G76 (thread cutting) vary by brand. A Okuma lathe might require different thread start parameters than a Doosan.

- Laser cutters: Use G00 for positioning but require G01 with low feed rates (10-50 mm/s) for precise cutting of thin materials.

- Water jet cutters: G-code controls both X/Y movement and water pressure, with G04 (dwell) critical for piercing thick aluminum.

Workholding devices also impact code—parts clamped off-center require G54 offsets adjusted accordingly, while tool changers need M06 (tool change) commands timed to avoid collisions.

Applications: Where G-Codes Drive Industry

G-code programming enables precision across sectors:

- Automotive: Engine blocks use G83 for deep oil passages and G71 for rough turning crankshaft journals.

- Electronics: PCB drills rely on G01 with micro-feeds (1-5 mm/min) to create 0.1mm holes without breaking tools.

- Prototyping: Rapid iteration with CAD/CAM-generated G-code lets shops produce a new prototype in 24 hours vs. 3-5 days with manual programming.

- Art and sculpture: Artists use G02/G03 for organic curves in metal sculptures, with spindle speeds adjusted to create textured surfaces.

In each field, the code must match material properties—titanium machining requires slower feed rates (50-100 mm/min) than aluminum (200-500 mm/min) to prevent tool wear.

Quality and Precision: Ensuring G-Code Delivers Results

Even perfect code can’t overcome poor execution—here’s how to maintain quality:

- Calibration: CNC machines need weekly calibration to ensure G01 moves 1mm when programmed. A 0.01mm per meter error accumulates on large parts, ruining tolerance.

- Inspection: After machining, CMMs verify dimensions against G-code coordinates. One study found 80% of out-of-spec parts trace back to uncalibrated machines, not bad code.

- Surface finish: G01 with constant feed rates (avoiding stops) reduces chatter marks. For Ra 0.8μm finishes, program F100-200 mm/min in steel.

- Tolerance control: Use G41/G42 radius compensation to account for tool wear. Replace tools when wear exceeds 0.02mm to stay within ±0.05mm tolerance requirements.

Adopting statistical process control (SPC) with G-code logging helps identify patterns—for example, if G03 arcs consistently run 0.01mm small, adjusting the machine’s backlash compensation fixes the issue.

Yigu Technology’s Perspective

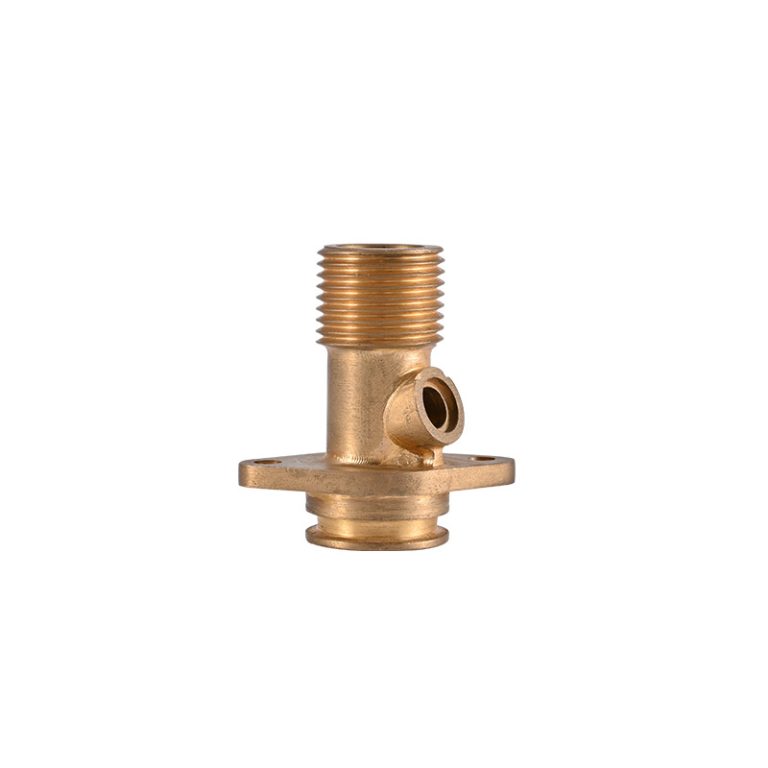

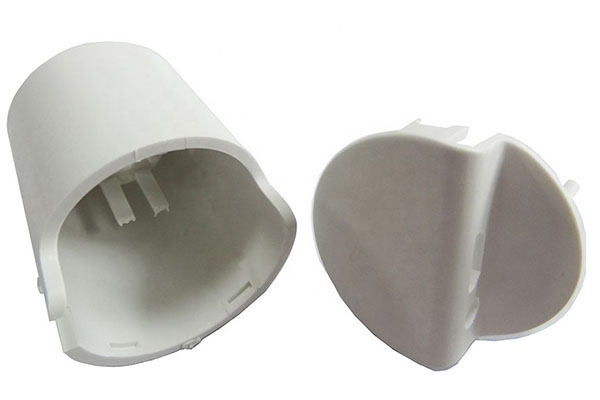

As a leading custom manufacturing supplier in China, Yigu Technology leverages G codes machining to deliver precision parts across industries. Our team combines manual programming for simple components with advanced CAD/CAM for complex aerospace and automotive parts, ensuring code efficiency and accuracy. We calibrate our CNC mills and lathes daily, using G-code verification software to catch errors before machining. Whether it’s optimizing feed rates for titanium or programming intricate engraving for custom tooling, we treat G-code as the foundation of quality—because we know that precise programming leads to precise parts.

FAQ

- What’s the most common G-code error, and how to fix it?

Missing or incorrect G20/G21 (inch/mm mode) causes dimension mismatches. Always start programs with G21 (metric) or G20 (inch) and verify with a dry run.

- Can G-codes be reused across different CNC machines?

Basic codes (G00, G01) work universally, but machine-specific codes (like G76 for threading) often need adjustment. Test with a dummy part first.

- How do I improve surface finish using G-codes?

Use G01 with constant feed rates (avoid G00 over the part), enable G41/G42 radius compensation, and program G04 dwells to clear chips before finishing passes.