Regular milling has serious problems when cutting hard, breakable materials like advanced ceramics and fiber-reinforced composites. The process often creates very high cutting forces, destroys tools quickly, damages the material below the surface, and produces rough finishes. These problems create major obstacles in making high-performance parts. Ultrasonic-Assisted Milling (UAM) offers a game-changing solution by completely changing how material gets removed to solve these challenges.

This technical guide gives you a thorough look at how UAM works and where it's used. We will break down the basic principles that make this technology perfect for breakable materials. Engineers and process experts will get a complete understanding of:

- How UAM reduces forces in a fundamental way.

- Important tool design and energy transfer efficiency.

- How to adjust settings for better surface quality.

- Real-world uses in advanced materials.

- New abilities like creating micro-textures.

Main Advantage: Force Comparison

The biggest benefit of UAM is the measurable reduction in cutting forces compared to regular milling. In regular processes, the constant contact between the tool and a breakable workpiece creates high stresses, causing uncontrolled crack growth and a brittle breaking way of removing material. This causes significant part damage and quick tool failure.

UAM adds high-frequency (20-40 kHz), small-movement (1-20 µm) vibrations to the cutting tool, usually along the tool's center line. This action changes a continuous cutting process into a series of high-speed impacts. This principle of stop-and-go cutting is the key to UAM's success. The tool repeatedly separates from the workpiece for a tiny fraction of a second, interrupting the continuous force application. This action reduces the average cutting forces and can shift how material gets removed from brittle breaking to a more controlled, bendable-like process. Additional benefits come from effects like acoustic softening, where ultrasonic energy appears to lower the material's resistance locally, and reduced friction between tool and chip due to the vibrational separation.

Force Reduction Methods

The "hammering effect" of the ultrasonic vibration is the main force reduction method. Each impact creates a small, controlled break, effectively pre-cracking the material ahead of the cutting edge. This dramatically lowers the energy needed for chip formation. Additionally, the stop-and-go contact significantly reduces the time-averaged friction between the tool rake face and the chip. This reduction in both mechanical and heat load is critical. Studies consistently show a reduction in cutting forces of 30-70% when machining materials like zirconia and silicon carbide compared to regular methods.

Impact on Tool and Material

The direct result of lower cutting forces is a chain reaction of process improvements. Reduced mechanical and heat loads on the cutting edge lead to significantly longer tool life, decreasing tool costs and machine downtime. For the workpiece, the lower forces and controlled material removal minimize the formation of edge chipping, micro-cracks, and other forms of below-surface damage. This is extremely important for parts where structural strength cannot be compromised.

| Feature | Regular Milling | Ultrasonic-Assisted Milling (UAM) |

| Primary Cutting Force | High, continuous | Significantly lower, stop-and-go |

| Material Removal Mode | Brittle Breaking | Bendable-like removal, micro-chipping |

| Tool Wear Rate | High (wearing away, chipping) | Lower (reduced heat & mechanical load) |

| Below-Surface Damage | Extensive (micro-cracks) | Minimal to none |

| Achievable Surface Finish | Poor to moderate | Excellent |

System Heart: Tool and Sonotrode

Understanding the hardware is essential to mastering UAM. The performance of the entire system depends on the efficient creation and transmission of ultrasonic energy from the power source to the cutting tool. This power system consists of several key parts, with the sonotrode being the most critical element for process success.

The UAM Power System

The journey of energy in a UAM system follows a clear path. It begins at the ultrasonic generator, which produces a high-frequency alternating current. This electrical signal is then fed to a transducer, which is typically built from piezoelectric ceramic discs. These discs expand and contract in response to the electrical signal, converting it into high-frequency mechanical vibration. This raw vibration is then transmitted to the sonotrode, also known as an acoustic horn or booster. The sonotrode acts as a mechanical amplifier, increasing the size of the vibration to a level suitable for machining before delivering it to the cutting tool.

Making Sonotrode Efficiency Better

The sonotrode is not just a passive part; its design controls the efficiency and stability of the entire process. Its main job is to amplify vibration and match the acoustic resistance of the transducer to the tool-workpiece interface. Efficient energy transfer is only possible with a well-designed sonotrode.

Material selection is crucial. Titanium alloys, particularly Ti-6Al-4V, are preferred for their excellent acoustic properties (low internal damping), high fatigue strength, and good machinability. For less demanding applications, high-strength steels may be used. The sonotrode's shape—often a stepped, cone-shaped, or exponential profile—is precisely calculated to amplify the vibration size to the desired level.

A key design challenge is managing stress and nodal points. The sonotrode must be clamped at a nodal point, a location of zero vibrational movement, to avoid energy loss to the machine structure. At the same time, the design must ensure that maximum stress concentrations within the horn remain below the material's fatigue limit to prevent early failure. Heat generated from internal material damping must also be managed, as it can change the system's resonant frequency.

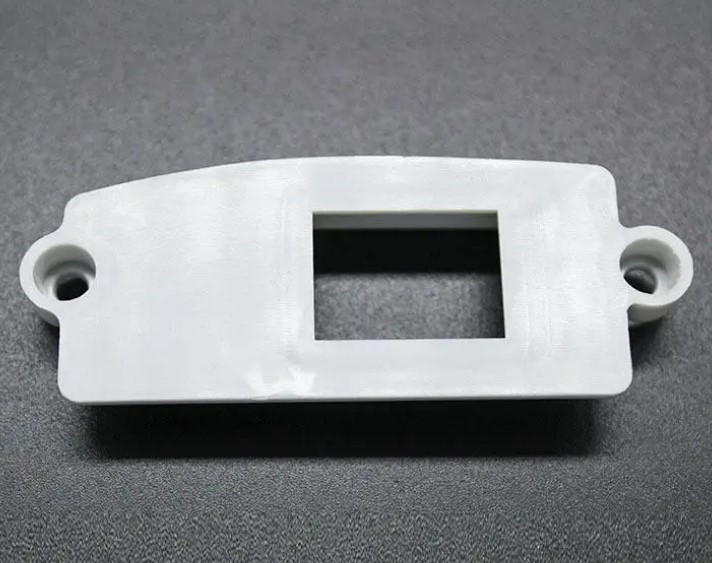

Tool Selection and Attachment

Standard milling tools can often be used with UAM systems, but the method of attachment is critical. The connection between the tool and the sonotrode must be extremely rigid to ensure efficient vibration transmission. Any flexibility or looseness in this joint will reduce the energy and make the system ineffective. Specialized tool holders with threaded or collet-based clamping mechanisms are designed to provide this high-stiffness connection. For micro-machining, the cutting tool and sonotrode are sometimes made as a single, one-piece unit to eliminate joint losses entirely.

Making the UAM Process Better

Achieving the best results with UAM requires a detailed understanding of how process settings interact to influence surface integrity. Surface integrity includes not only surface roughness (Ra) but also the presence of leftover stresses, micro-cracks, and other forms of below-surface damage. By carefully adjusting the settings, an operator can customize the process for either maximum material removal or perfect surface quality.

The Role of Frequency

The ultrasonic frequency, typically in the 20-40 kHz range, is generally a fixed characteristic of the transducer and sonotrode system. However, its effect is fundamental. A higher frequency means more impacts per unit of time for a given cutting speed. This increases the number of stop-and-go cutting events, which promotes a smoother cutting action and can contribute to a finer surface finish. The frequency sets the baseline for the entire movement interaction between the tool and the workpiece.

Frequency and Amplitude Working Together

While frequency is often fixed, vibration amplitude is a key adjustable setting. The interaction between frequency and amplitude is critical. A high frequency combined with a small amplitude (e.g., 1-5 µm) is ideal for finishing operations. The rapid, small impacts gently remove material, producing an excellent surface finish with minimal below-surface damage. On the other hand, a lower frequency system paired with a larger amplitude (e.g., 10-20 µm) can significantly increase the material removal rate (MRR). The more forceful impacts remove larger volumes of material per vibration cycle, making it suitable for roughing, though it might slightly increase surface roughness.

Adjusting Key Settings

Beyond the ultrasonic settings, regular machining settings must be adjusted to work together with the vibration.

- Vibration Amplitude: As a primary adjustable setting, increasing amplitude generally increases MRR. However, an extremely high amplitude can lead to increased tool wear and may make the surface finish worse if not balanced with a lower feed rate. The best amplitude is a balance between productivity and quality.

- Feed Rate: Feed rate has a major impact on surface integrity. A lower feed rate allows for more ultrasonic impacts per unit length of cut. This increased overlap in vibrational impacts is directly responsible for the dramatic improvement in surface finish seen in UAM. For finishing passes, extremely low feed rates are used.

- Spindle Speed (rpm): The relationship between spindle speed and ultrasonic frequency creates a unique movement pattern on the machined surface. The combination of tool rotation and axial vibration results in a spiral tool path. Making the spindle speed work well with the frequency can create specific surface textures or ensure that the cutting edge is constantly engaging new material, which can help in reducing localized heat damage.

- Depth of Cut: For breakable materials, the axial depth of cut should be kept relatively low to avoid starting large-scale brittle breaks. UAM allows for a greater depth of cut compared to regular milling, but moderation is still key to maintaining a bendable-like removal process.

| Setting | Effect on Surface Roughness (Ra) | Effect on Material Removal Rate (MRR) | General Recommendation |

| Vibration Amplitude | Increases (if too high) | Increases | Start low for finishing, increase for roughing |

| Feed Rate | Increases | Increases | Use low feed rates for best surface integrity |

| Spindle Speed | Complex interaction | Minor effect | Optimize based on frequency for desired path |

| Depth of Cut | Increases | Increases | Keep low for breakable materials to avoid breaking |

UAM Applications in Practice

The theoretical benefits of UAM translate into real advantages in high-value manufacturing sectors. The technology has proven essential for machining materials that are otherwise economically or technically impossible to process with regular methods.

Machining Advanced Ceramics

Advanced technical ceramics like Silicon Nitride (Si₃N₄) and Zirconia (ZrO₂) are valued for their hardness, wear resistance, and high-temperature stability. However, these same properties make them extremely difficult to machine.

- Challenge: Regular milling of these ceramics results in severe tool wearing away, unpredictable edge chipping, and the spread of below-surface micro-cracks that compromise the part's structural integrity. The high forces required often lead to catastrophic tool or workpiece failure.

- UAM Solution: The stop-and-go cutting and reduced forces of UAM prevent the formation of large, uncontrolled cracks. The process enables the creation of complex features like small-diameter holes, sharp internal corners, and thin walls with high precision and minimal defects. In machining medical-grade Zirconia for dental implants, UAM has demonstrated the ability to achieve a surface finish of Ra < 0.1 μm directly from the milling process. This often eliminates the need for extensive and costly post-process grinding and polishing.

Overcoming CFRP Delamination

Carbon Fiber Reinforced Polymers (CFRP) are critical in the aerospace and automotive industries for their high strength-to-weight ratio. Machining them, particularly drilling, is a major challenge.

- Challenge: When a regular drill exits a CFRP laminate, the cutting forces can push the bottom layers away before they are cut, causing delamination. On entry, fibers can be pulled out rather than cleanly cut. The wearing nature of the carbon fibers also leads to extremely rapid tool wear.

- UAM Solution: UAM, particularly in its rotary ultrasonic machining (RUM) variant, excels at drilling CFRP. The high-frequency impact of the diamond-abrasive tool cleanly cuts the carbon fibers instead of pushing or pulling them. The significantly lower thrust force dramatically reduces the risk of exit-side delamination. Industry results have shown a 90% reduction in the delamination factor when drilling CFRP composites compared to regular twist drills. The lower process temperatures also prevent heat damage to the polymer matrix, preserving the material's integrity around the machined feature.

Beyond Milling: Micro-Texturing

Ultrasonic-assisted milling offers abilities that extend beyond simple material removal. One of the most exciting advanced applications is the ability to create controlled, functional micro-textures on a material's surface. This is not a random side effect of the process but a deliberate manufacturing technique achieved by controlling the tool's movement path.

The Movement Principle

Surface texturing is achieved through the principle of movement superposition. The final surface shape is a result of the combined motion of the primary tool path (e.g., straight feed), the tool rotation (spindle speed), and the secondary high-frequency vibration. By precisely controlling the ratio of spindle speed to vibration frequency, a predictable, repeating pattern can be printed onto the surface. This process is similar to a microscopic Spirograph, where the tool tip traces a complex but controllable path, leaving behind a structured texture of micro-dimples, grooves, or cross-hatched patterns.

Creating Functional Surfaces

This ability to engineer surface shape opens up a new realm of possibilities for creating functional surfaces directly during the machining stage. This in-process texturing is far more efficient than secondary processes like laser ablation or chemical etching.

- Water-Repelling/Water-Attracting Surfaces: By creating specific patterns and feature densities, the surface's wetting characteristics can be controlled. This can be used to create self-cleaning or anti-icing surfaces.

- Improved Lubrication: Creating an array of micro-dimples on a bearing or piston surface can act as lubricant reservoirs. These textures trap and distribute oil, significantly reducing friction and wear in moving systems.

- Enhanced Bio-compatibility: For medical implants, micro-texturing the surface can promote cell adhesion and bone integration. The specific shape can guide cell growth, leading to faster healing and a stronger bond between the implant and bone.

- Aesthetic/Optical Effects: Controlled micro-textures can be used to manipulate light, creating surfaces with unique decorative finishes, specific reflective properties, or anti-glare characteristics.

Future of Brittle Machining

Ultrasonic-assisted milling has definitively proven its value in the precision machining of hard and breakable materials. By fundamentally changing the tool-workpiece interaction to reduce cutting forces, it delivers superior surface integrity, minimizes below-surface damage, and significantly extends tool life. The ability to machine complex features in advanced ceramics and eliminate delamination in CFRPs addresses critical manufacturing challenges.

As industries continue to push the boundaries of material science, relying more on advanced ceramics, composites, and glasses, the limitations of regular machining will become more pronounced. UAM is no longer a niche, academic technology. It is rapidly transitioning into an essential, enabling process for any organization involved in high-performance manufacturing, unlocking new possibilities in part design and functionality.