Introduction

Definition of Plastic Die

A plastic die, also known as a plastic mold, is a specialized tool used in the manufacturing process to shape plastic materials into desired forms. It serves as a cavity or a set of cavities into which molten plastic is injected, extruded, or compressed. Once the plastic cools and solidifies within the die, it takes on the precise shape defined by the die's interior structure.

Plastic dies are crucial components in the plastic manufacturing industry, playing a fundamental role in mass - producing a wide range of plastic products. They are used in various plastic - forming processes, such as injection molding, blow molding, compression molding, and extrusion molding. In injection molding, for example, plastic pellets are melted and then forced into a closed - cavity plastic die under high pressure. In blow molding, a parison (a tube - like piece of molten plastic) is inflated inside a die to form hollow products like bottles.

The importance of plastic dies in industrial production cannot be overstated. They enable the efficient and consistent production of high - quality plastic products with complex geometries and tight tolerances. In fact, a significant portion of the plastic products we use daily, from consumer electronics and automotive parts to medical devices and packaging materials, are made possible by plastic dies. According to industry statistics, over 70% of plastic products in the market are manufactured using plastic dies. This high percentage reflects their indispensable position in modern manufacturing, as they not only ensure product quality but also contribute to cost - effective production by enabling high - volume manufacturing runs.

Guide Die Forming

Process Explanation

Step - by - step Introduction

- Material Preparation: First, select the appropriate plastic material according to the product requirements. For example, if high - strength and heat - resistance are needed, materials like polycarbonate (PC) or acrylonitrile butadiene styrene (ABS) may be chosen. The plastic is usually in the form of pellets. These pellets should be dried properly to remove any moisture. Moisture in the plastic can cause defects such as bubbles in the final product during the forming process. For instance, ABS pellets are typically dried at around 80 - 90°C for 2 - 4 hours.

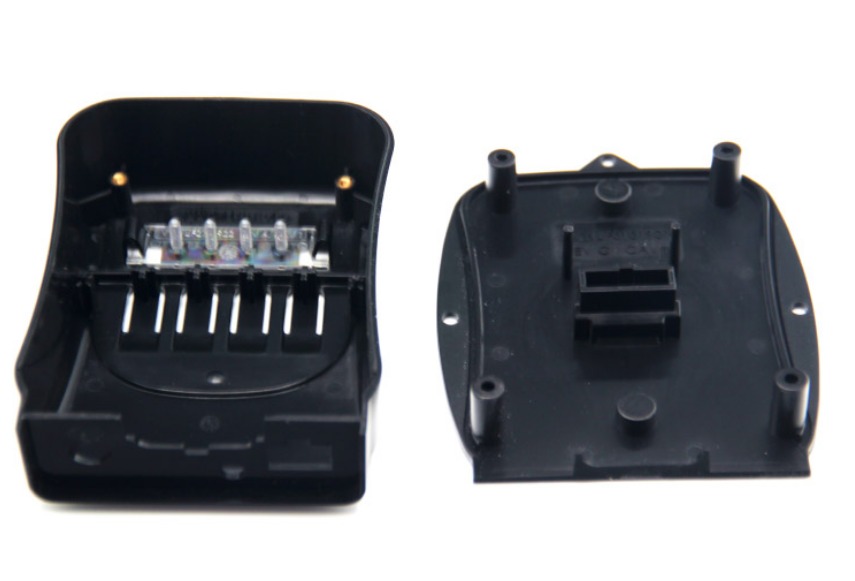

- Mold Installation: The guide die is carefully installed into the molding machine. The die consists of two main parts: the fixed half (usually attached to the stationary platen of the machine) and the moving half (connected to the movable platen). Precise alignment of the two halves is crucial. Any misalignment can lead to uneven wall thickness in the molded product or even prevent the die from closing properly. The installation process may involve using alignment pins and bolts to secure the die firmly in place.

- Heating and Melting: The plastic pellets are fed into the heating barrel of the molding machine. Inside the barrel, there are heating elements that raise the temperature of the plastic to its melting point. For example, the melting point of polyethylene (PE) is around 110 - 130°C. As the temperature rises, the plastic gradually changes from a solid - state to a molten state, becoming viscous and flowable.

- Injection or Compression:

- Injection: In injection molding, the molten plastic is forced into the guide die cavity through a nozzle by a reciprocating screw or a plunger. High pressure is applied during this stage. The injection pressure can range from 50 - 200 MPa depending on the plastic material and the complexity of the product design. For small and simple plastic parts, a lower pressure of around 50 - 80 MPa may be sufficient, while for large and complex parts, pressures up to 200 MPa may be required.

- Compression: In compression molding, the pre - measured amount of molten plastic is placed between the two halves of the open guide die. Then, the moving half of the die moves towards the fixed half, compressing the plastic and forcing it to fill the cavity. The compression force is adjusted according to the size and shape of the product.

- Cooling and Solidification: Once the plastic has filled the die cavity, it needs to cool down to solidify. Cooling channels are built into the die, through which a cooling medium (usually water) circulates. The cooling time varies depending on the thickness and material of the product. For a thin - walled plastic part with a thickness of 1 - 2 mm, the cooling time may be only a few seconds, while for a thick - walled part with a thickness of 5 - 10 mm, the cooling time can be several minutes.

- Ejection: After the plastic has solidified, the die opens, and the molded product is ejected from the die cavity. Ejection pins or a stripper plate are used to push the product out. The ejection force should be carefully controlled to avoid damaging the product.

Key Parameters and Their Influence

- Temperature:

- Melting Temperature: As mentioned above, different plastic materials have different melting points. If the temperature in the heating barrel is too low, the plastic may not melt completely, resulting in a product with uneven texture and poor mechanical properties. On the other hand, if the temperature is too high, the plastic may degrade, changing its chemical properties and causing discoloration or brittleness.

- Mold Temperature: The temperature of the guide die also affects the quality of the product. A higher mold temperature can reduce the stress in the molded part and improve its surface finish. However, it may also increase the cooling time. For example, when molding PC, a mold temperature of 80 - 120°C is often recommended for good surface quality.

- Pressure:

- Injection/Compression Pressure: Higher pressure can ensure better filling of the die cavity, especially for complex - shaped products. But excessive pressure can cause flash (thin layers of excess plastic around the product edges), over - packing (resulting in high internal stress in the product), and even damage to the die. The relationship between pressure and product quality can be seen in the following simple graph:

| Pressure Level | Flash Risk | Internal Stress | Filling Completeness |

| Low | Low | Low | Incomplete for complex shapes |

| Medium | Medium - Low | Medium | Good for most simple - medium complexity parts |

| High | High | High | Complete for complex shapes, but with risks |

- Time:

- Injection Time: A short injection time can lead to incomplete filling of the die cavity, while a long injection time may cause the plastic to cool prematurely in the barrel or nozzle, affecting the flowability.

- Cooling Time: As mentioned, an insufficient cooling time may result in the product deforming when ejected from the die due to incomplete solidification. A proper cooling time ensures that the product has the required strength and dimensional stability.

Types of Guide Die Forming

Different Methods

- Compression Molding: In this method, as described before, the plastic material is placed in a pre - heated open die. The die is then closed, and the material is compressed into the shape of the cavity. It is suitable for thermosetting plastics like phenolic resins and some thermoplastics. The process is relatively simple and does not require high - pressure injection equipment. However, it is less suitable for products with complex internal structures.

- Injection Molding: This is one of the most widely used methods. It is highly efficient for mass - production. Injection molding can produce products with high precision and complex geometries, including products with thin walls and fine details. But it requires more expensive equipment and higher - pressure operation.

- Transfer Molding: Similar to injection molding, but the plastic is first pre - heated and then transferred into the die cavity through a runner system. It is often used for molding thermosetting plastics with inserts. The process can ensure good adhesion between the plastic and the inserts.

The following table summarizes the comparison of these methods:

| Forming Method | Suitable Plastics | Equipment Cost | Product Complexity | Production Efficiency |

| Compression Molding | Thermosetting plastics, some thermoplastics | Low - Medium | Low - Medium, not suitable for complex internal structures | Medium - Low |

| Injection Molding | Most thermoplastics, some thermosetting plastics | High | High, can produce complex geometries | High |

| Transfer Molding | Thermosetting plastics with inserts | Medium - High | Medium - High, good for inserts | Medium |

Die Cutting Plastic Materials

Principles of Die Cutting

Mechanics Behind

Die cutting of plastic materials is a process that involves the use of a sharp - edged die to cut, shape, or crease plastic sheets or films. The basic mechanics behind die cutting are relatively straightforward. A die, which is essentially a custom - made cutting tool, is pressed against the plastic material with sufficient force. This force is typically applied by a die - cutting machine, such as a flat - bed die - cutting press or a rotary die - cutting machine.

As shown in the figure below, in a flat - bed die - cutting setup, the die (1) is fixed on a platen (2). The plastic material (3) is placed on a table (4). When the machine operates, the upper platen with the die descends, and the die cuts through the plastic material along its pre - designed shape. The pressure applied by the machine is evenly distributed across the die, ensuring a clean and precise cut.

The cutting action is based on the principle of shear stress. When the die presses into the plastic, the material is subjected to shear forces that exceed its shear strength, causing it to break along the cutting edge of the die. For example, when cutting a thin plastic film, a relatively low - pressure die - cutting process can be used as the film has a lower shear strength. However, when cutting a thick plastic sheet, a higher - pressure machine may be required to overcome the greater resistance of the material.

Factors Affecting Cutting Precision

- Tool Sharpness: A sharp die is crucial for achieving high - precision cuts. A dull die will not cut cleanly through the plastic material. Instead, it may tear or crush the material, resulting in rough edges and inaccurate cuts. For instance, in the production of small plastic components for electronics, a sharp die can ensure that the edges of the cut - out parts are smooth and the dimensions are within the required tolerances. Over time, dies can become dull due to wear and tear from repeated use. Regular maintenance, such as sharpening or replacing the die, is necessary to maintain cutting precision.

- Material Thickness and Hardness: Thicker plastic materials are generally more difficult to cut precisely. The increased thickness means that more force is required to cut through the material, and it becomes harder to control the cutting depth accurately. For example, when cutting a 1 - mm - thick plastic sheet compared to a 0.1 - mm - thick sheet, the thicker sheet may experience more deviation in the cutting line. Harder plastic materials also pose challenges. Materials like polypropylene (PP) with high - density and high - stiffness require more powerful die - cutting equipment to ensure clean cuts. If the machine's pressure is not sufficient for a hard plastic material, the die may not be able to cut through it completely, leading to incomplete or inaccurate cuts.

- Machine Calibration: The proper calibration of the die - cutting machine is essential. If the machine is not calibrated correctly, the pressure applied during the cutting process may be uneven. This can cause the die to cut deeper in some areas and shallower in others, resulting in inconsistent cut quality. For example, if the pressure on one side of the die - cutting platen is 10% higher than the other side, the cut edges of the plastic material will have different depths, affecting the overall precision of the cut parts. Regular calibration checks and adjustments of the machine are necessary to maintain consistent cutting precision.

Comparison and Selection

Comparing Die Forming and Die Cutting

When it comes to plastic manufacturing, understanding the differences between die forming and die cutting is crucial for making informed decisions. The following table outlines the key differences between the two processes in terms of process, cost, efficiency, and applicable materials:

| Comparison Items | Die Forming | Die Cutting |

| Process | Molten plastic is shaped within a die cavity through injection, compression, or other methods. Involves multiple steps such as material melting, cavity filling, cooling, and solidification. | A sharp - edged die cuts, shapes, or creases plastic sheets or films. The die is pressed against the plastic material with force, and the cutting action is based on shear stress. |

| Cost | Higher initial investment for die - making and equipment, especially for injection molding with high - pressure and complex - shaped dies. But the unit cost per product can be low for high - volume production due to economies of scale. | Lower die - making cost for simple flat - bed dies, while rotary dies can be expensive. Equipment cost can vary depending on the type of die - cutting machine. Overall, the cost is often more suitable for small - to medium - scale production in terms of die - making. |

| Efficiency | High - volume production can be achieved with injection molding, where thousands of parts can be produced per hour. However, the setup time for die - changing and process adjustment can be relatively long. | Rotary die - cutting offers high - speed continuous cutting, suitable for high - volume production of simple - shaped products like labels. Flat - bed die - cutting is slower, more suitable for small - batch production or products with complex shapes. |

| Applicable Materials | Most thermoplastics and some thermosetting plastics can be used. Different plastics have different melting points and flow characteristics, which need to be considered during the forming process. | A wide range of plastic materials can be die - cut, from thin films to thick sheets. However, the thickness and hardness of the material affect the cutting process, and harder or thicker materials may require more powerful equipment. |

How to Choose the Right Method

The choice between die forming and die cutting depends on several factors:

- Product Requirements:

- Complexity of Shape: If the product has a complex three - dimensional shape with internal structures, die forming methods like injection molding are more suitable. For example, a plastic automotive dashboard with multiple curves, holes, and functional components is better made through injection molding. On the other hand, if the product is a simple two - dimensional shape, such as a plastic label or a flat gasket, die cutting may be sufficient.

- Precision and Tolerance: Die forming processes can achieve high precision and tight tolerances, especially in injection molding, which is suitable for products that require high - accuracy manufacturing, like medical device components. Die cutting also can achieve good precision, but for extremely high - precision requirements in three - dimensional aspects, die forming may be a better choice.

- Material Characteristics:

- Thermoplastic vs. Thermosetting Plastics: Thermoplastics can be used in both die forming and die cutting. However, thermosetting plastics are mainly used in die forming processes such as compression molding and transfer molding because they undergo a chemical curing reaction during the molding process and cannot be re - melted like thermoplastics.

- Material Thickness and Hardness: Thick and hard plastic materials may be more difficult to die - cut and may require more powerful die - cutting equipment. In such cases, die forming may be a more practical option as the plastic is in a molten state during the forming process, making it easier to shape.

- Production Scale:

- High - Volume Production: For high - volume production, die forming methods like injection molding are more cost - effective in the long run due to their high - speed production capabilities and the ability to produce a large number of identical parts with consistent quality. Die cutting can also be used for high - volume production if the product shape is simple and can be processed by rotary die - cutting machines.

- Low - Volume and Prototyping: For low - volume production or prototyping, die cutting may be a more flexible and cost - efficient choice. The lower die - making cost and shorter setup time of die cutting make it easier to produce small batches of products or quickly test different design concepts.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology has a profound understanding of the plastic die field. We believe that the continuous development of technology brings new opportunities and challenges to plastic die manufacturing. For example, the application of advanced CAD/CAM technology in plastic die design can significantly improve design efficiency and accuracy. By using these digital technologies, we can simulate the forming process in advance, optimize the die structure, and reduce the number of physical prototypes, thus shortening the development cycle and reducing costs.

Understanding customer needs is at the core of our business. We work closely with customers to deeply understand their product requirements, whether it's the complexity of the product shape, the required material properties, or the production volume. Based on this understanding, we provide customized die solutions. For small - batch production with complex product shapes, we may recommend flat - bed die - cutting methods combined with some innovative die - making techniques to ensure cost - effectiveness and high - quality product output. Our professional team of engineers and technicians is always ready to provide technical support throughout the entire process, from design to production, to ensure that our customers' projects are successfully completed.