Plastic & Metal industry knowledge

Transfer the value information of rapid prototypes, mold and injection molding industry

How Are Plastic Parts Made Used Impacting Our World?

The Manufacturing Landscape of Plastic Parts The production of plastic parts is a cornerstone of modern manufacturing, with a wide array of methods employed to create the diverse plastic products...

Why Injection Molding Inc Beating Heart of Plastic Manufacturing?

1. The Basics of Injection Molding 1.1 The Process Injection molding is a highly efficient and widely used manufacturing process for producing plastic parts. It involves several key steps that...

What Is Mold Masters: Engineering Behind Mold Manufacturing?

Introduction In the vast realm of plastic manufacturing, Mold Masters stands as a towering figure, a global leader that has been shaping the industry for over five decades. Since its...

What Is Plastic Revolution: Unlocking Plastic Manufacturing?

Introduction to the Plastic Revolution The importance of the plastic revolution to the plastic manufacturing industry cannot be overstated. It has not only led to the creation of countless new...

What Makes Gear Factory Operations Key to Success?

Introduction In the vast and complex landscape of industrial manufacturing, gear factories play a pivotal role. Gears are the unsung heroes that power countless machines across various sectors, from automotive...

What Makes China’s Plastic Industry a Powerhouse?

Introduction: The Prominence of China's Plastic Industry In the global manufacturing landscape, China's plastic industry stands as a colossus. With a production volume that has been soaring over the years,...

How Additive Manufacturing Evolving Traditional Craftsmanship?

1. Introduction In the dynamic landscape of modern manufacturing, both additive manufacturing (AM), commonly known as 3D printing, and traditional craftsmanship hold significant positions. Traditional craftsmanship, with its roots deeply...

How High-Quality 3D Printing Revolutionizing Manufacturing’s Future?

1. Introduction In recent years, 3D printing technology has emerged as a revolutionary force across various industries, from healthcare to aerospace, from automotive to consumer goods. What was once a...

How 3D Printing Unleashing Power of Metal for Parts?

The Power Unleashed: Advantages of 3D Printing for Metal Parts Design Freedom Redefined 3D printing has revolutionized the design landscape, especially when it comes to metal parts. Traditional manufacturing methods...

How Stainless Steel 3D Printing Revolutionizing Manufacturing?

1. How Stainless Steel 3D Printing Differs from Traditional Manufacturing 1.1 A Comparative Analysis Stainless steel 3D printing represents a paradigm shift from traditional manufacturing methods. Let's take a closer...

How Is 3D Printing with Steel Driving Progress Evolution?

Understanding 3D Printing with Steel 3D printing, also known as additive manufacturing, has revolutionized the manufacturing industry by enabling the creation of complex three - dimensional objects layer by layer...

What’s Plastic Mold Manufacturers Crafting the Future?

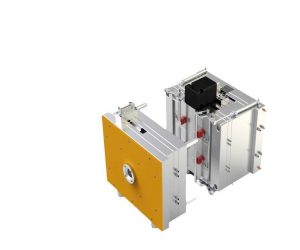

1. Manufacturing Processes: A Deep Dive 1.1 Injection Molding 1.1.1 Process Explanation Injection molding is one of the most widely used manufacturing processes in the plastic industry. The process begins...

What’s Inside Track on Mold Manufacturing in Plastic Revolution?

Introduction to Mold Manufacturing in the Plastic Revolution In the ever - evolving landscape of modern manufacturing, the plastic revolution has been nothing short of transformative. At the heart of...

What’s Revolutionary Impact of Plastic Molding Manufacturing?

Introduction to Plastic Molding Manufacturing Plastic molding manufacturing is a cornerstone of modern manufacturing, playing a pivotal role in a vast array of industries. It is the process of shaping...

How 3D Printing Revolutionizing Future of Mold Manufacturing?

Traditional Mold Manufacturing Methods Overview of Conventional Techniques Traditional mold manufacturing methods have been the backbone of the manufacturing industry for decades. These methods primarily include casting and mechanical processing,...

How Custom Molds Crafting Unique Products with Precision?

Understanding Custom Molds Definition and Basics Custom molds, in the manufacturing realm, are specialized tools meticulously crafted to shape raw materials into specific, often unique, products. Unlike standard molds that...

How Injection Molding Craft High-Quality Products Precision?

Understanding Injection Molding Basics What is Injection Molding? Injection molding is a widely - used manufacturing process that plays a crucial role in various industries. It involves injecting molten material,...

How Injection Molding Mastery Create High-Quality Products Precision?

Understanding Injection Molding Basics Injection molding is a manufacturing process that has revolutionized the production of plastic and some metal parts. It involves injecting molten material into a mold cavity,...

How Insert Molding Mastery Crafting Products with Precision?

Introduction In the dynamic realm of modern manufacturing, achieving precision and efficiency is not just a goal but a necessity for staying competitive. One technique that has emerged as a...

How We Master Properties Applications of Versatile Nylon?

Introduction Nylon, a remarkable synthetic material, has woven its way into the fabric of modern life with an incredibly wide range of applications. Since its invention, nylon has become a...