Introduction: The Prominence of China's Plastic Industry

In the global manufacturing landscape, China's plastic industry stands as a colossus. With a production volume that has been soaring over the years, China has firmly established itself as one of the leading players in the global plastics market. In 2023, for instance, China's cumulative output of plastic products reached a staggering 74.885 million tons,showing a 3% growth compared to the previous year, according to the data from the relevant report. This growth rate not only reflects the industry's vibrant development momentum but also indicates its increasing influence in the global market.

The plastic products from China are omnipresent across the world. They range from the everyday plastic containers in kitchens, the packaging materials for various consumer goods, to the intricate plastic components in high - tech electronics and automotive parts. Such wide - spread application is a testament to the industry's scale and the diversity of its product offerings. But what exactly has propelled China to achieve this remarkable status in the plastic industry? Is it the vast resources, advanced technology, or a combination of multiple factors? This is precisely what we will explore in this article, delving deep into the key elements that have made China's plastic industry a powerhouse.

Technological Advancements: Precision and Innovation

Precision Molding Technologies

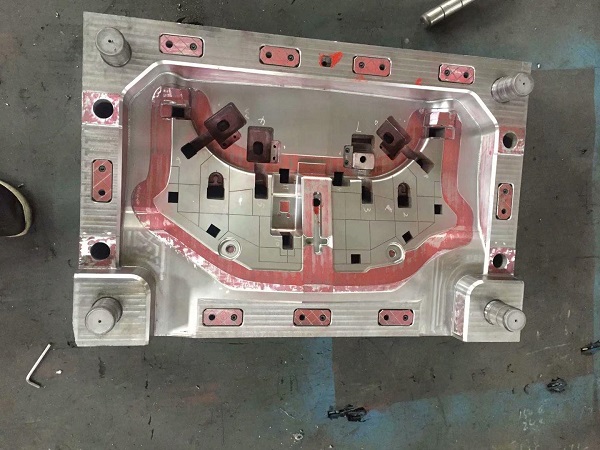

In China's plastic industry, precision molding technologies have reached a high level of sophistication, significantly enhancing the industry's competitiveness. The four main types of precision molding technologies - injection molding, blow molding, extrusion molding, and compression molding - are widely used across various sectors.

Injection molding, the most prevalent method, is crucial in producing a wide range of products. In the automotive industry, for Yigu Technology example, it is used to create intricate parts like dashboard components, which require high precision in shape and dimension. A leading Chinese automotive parts manufacturer reported that after upgrading its injection - molding equipment and processes, the production efficiency of dashboard components increased by 25%, and the defect rate dropped from 5% to 2%. In the electronics industry, injection molding is employed to make components such as mobile phone casings. With the pursuit of thinner and lighter electronic devices, the precision requirements for plastic components are extremely high. Chinese manufacturers have mastered the technology to produce mobile phone casings with wall thickness tolerances as low as ±0.05mm, meeting the strict demands of global electronics brands.

Blow molding is essential for manufacturing hollow plastic products, such as plastic bottles and containers. In the packaging industry, large - scale blow - molding machines in China can produce high - volume, high - quality plastic bottles with precise control over the wall thickness and shape. A well - known packaging company in China can produce 500ml PET plastic bottles at a rate of 2000 bottles per hour using advanced blow - molding technology, and the product qualification rate is over 98%. This high - speed and high - quality production not only meets the domestic market demand but also enables Chinese - made plastic packaging products to be exported globally.

Yigu Technology Extrusion molding is mainly used for manufacturing continuous - shaped products like plastic pipes and profiles. In the construction industry, plastic pipes produced by extrusion molding are popular due to their corrosion - resistance, low cost, and easy installation. China is a major producer of plastic pipes, and the annual output of plastic pipes in 2023 reached 18 million tons. Advanced extrusion - molding technologies allow for the production of pipes with complex cross - sectional shapes and high - performance properties, such as pipes with enhanced heat - resistance for hot - water supply systems.

Compression molding is often used for manufacturing products with simple shapes but high - volume requirements, like some plastic plates and basic plastic parts. In the furniture industry, compression - molded plastic parts are used in the production of plastic chairs and tables. Chinese manufacturers can produce large - scale plastic chair components with consistent quality through compression molding, and the production cycle for a single chair component can be as short as 3 - 5 minutes, contributing to the high - volume and cost - effective production of plastic furniture.

Material Innovation

Material innovation is another key factor driving the success of China's plastic industry. The development and application of new - generation plastic materials, such as high - performance plastics, engineering plastics, and biodegradable plastics, have opened up new possibilities for the industry.

High - performance plastics, with excellent mechanical properties, heat - resistance, and chemical resistance, are increasingly used in high - end manufacturing. For instance, polyetheretherketone (PEEK), a high - performance plastic, is used in aerospace components and high - precision mechanical parts. A Chinese aerospace research institute has successfully used domestically produced PEEK materials to manufacture some non - structural parts of aircraft, reducing the weight of the components by 20% compared to traditional metal materials while maintaining high - strength and heat - resistance performance.

Engineering plastics, like acrylonitrile butadiene styrene (ABS) and polycarbonate (PC), are widely used in the electronics, automotive, and construction industries. In the electronics industry, ABS is commonly used for the production of electronic device housings due to its good processability and impact resistance. A large - scale Chinese electronics manufacturer produces millions of ABS - made laptop housings annually, and through continuous material innovation and process improvement, the company has reduced the material cost per housing by 10% while improving the product's flame - retardant and anti - static properties.

Biodegradable plastics have gained significant attention in recent years due to environmental concerns. China has made remarkable progress in the research and development of biodegradable plastics, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA). Some Chinese companies have successfully developed biodegradable plastic packaging materials for the food industry. A food packaging company in China has replaced traditional non - biodegradable plastic packaging with PLA - based biodegradable packaging. The new packaging not only meets the food - safety standards but also has a degradation rate of over 80% within six months in a simulated natural environment, greatly reducing the environmental impact of plastic waste.

Companies like Kingfa Sci. & Tech. Co., Ltd. have been at the forefront of material innovation. Kingfa has developed a series of high - performance and functional plastic materials, including flame - retardant plastics, high - strength engineering plastics, and biodegradable plastics. Their products are widely used in various industries, and their continuous R & D efforts have not only driven the development of the company but also promoted the overall technological progress of the plastic industry in China.

Comprehensive Industrial Chain: Strength in Integration

Upstream: Stable Raw Material Supply

The upstream of China's plastic industry plays a fundamental role in ensuring the stable supply of raw materials. The production of plastic raw materials is closely related to key resources such as crude oil, coal, and natural gas. As of 2023, China is one of the largest consumers and producers of plastic raw materials globally.

Crude oil is a primary source for many plastic raw materials. In 2023, China's crude oil processing volume reached 705.848 million tonsproviding a stable feedstock base for the production of plastics like polyethylene (PE) and polypropylene (PP). The domestic petrochemical industry has a large number of leading enterprises with significant production capacity. For example, China National Petroleum Corporation (CNPC) and China Petrochemical Corporation (Sinopec) are giants in the field. Sinopec's annual capacity for producing basic plastic raw materials such as PE and PP exceeds 10 million tons. These large - scale enterprises not only have advanced refining and chemical technologies but also a vast network of production bases across the country, which can effectively guarantee the supply of raw materials for the domestic plastic industry.

Midstream: Robust Manufacturing Capabilities

The midstream of the plastic industry, the manufacturing of plastic products, is where China's industrial strength truly shines. This segment encompasses a wide range of products, each with its own market demand and technical requirements.

Plastic pipes are another important product in the mid - stream manufacturing. In 2023, the output of plastic pipes in China reached 1800 万吨. They are extensively used in the construction industry for water supply and drainage systems, in the agricultural industry for irrigation, and in the infrastructure construction for gas pipelines and cable protection. Leading enterprises in the plastic pipe manufacturing industry, such as China Liansu Group, have a comprehensive product range and advanced production technology. China Liansu has a large number of production bases across the country, with an annual plastic pipe production capacity of over 3 million tons, and its products meet high - quality standards both at home and abroad.

Injection - molded products cover a wide variety of items, from small daily - use products like plastic cups and toys to large - scale industrial components. There are more than 10,000 injection - molding enterprises in China, and many of them have advanced injection - molding machines and skilled technicians. For Yigu Technology example, in the toy - making industry, many Chinese injection - molding enterprises can produce high - quality plastic toys in large quantities, meeting the high - volume and high - quality requirements of international toy brands. These enterprises can quickly adjust production according to market demand, and some can produce tens of thousands of injection - molded toy products per day.

Downstream: Diverse Application Fields

The downstream application fields of the plastic industry in China are extremely diverse, which provides strong impetus for the development of the entire industry.

In the packaging industry, plastics are everywhere. Plastic packaging accounts for a significant proportion of the total packaging market. For example, in the food packaging sector, plastic bags, plastic containers, and plastic wrapping films are commonly used. A large - scale food packaging enterprise in China, like Hangzhou Wahaha Group, uses a large amount of plastic packaging materials for its beverages and food products. The company's annual consumption of plastic packaging materials reaches hundreds of thousands of tons, and it has strict requirements for the quality and safety of plastic packaging to ensure food quality and shelf - life.

In the construction industry, plastics are used in many aspects. Plastic pipes, as mentioned before, are an essential part of building water supply and drainage systems. In addition, plastic insulation materials are also widely used. For instance, in high - rise buildings in big cities like Shanghai and Shenzhen, plastic - based insulation materials are used to improve the energy - efficiency of buildings. These materials can effectively reduce heat transfer, save energy for heating and cooling systems, and meet the requirements of modern building energy - conservation standards.

The automotive industry also relies heavily on plastics. Plastic components are used in automotive interiors, such as dashboards, seats, and door panels, as well as in some exterior parts like bumpers. Chinese automotive manufacturers, such as BYD, use a large number of lightweight plastic components in their vehicle production. By using plastic components, the weight of the vehicle can be reduced, which not only improves fuel efficiency but also enhances the vehicle's performance. The use of plastic in automotive manufacturing is also increasing due to its good moldability, which allows for the production of complex - shaped components.

In the electronics industry, plastics are used for the housings of electronic devices, circuit boards, and insulation materials. With the rapid development of the electronics industry in China, the demand for high - performance plastics in this field is also growing. For example, in the production of smartphones, high - strength and heat - resistant plastics are used for the phone casings to protect the internal components and meet the requirements of thin and light product design. A leading Chinese smartphone manufacturer, Xiaomi, uses advanced plastic materials in its phone production, and the company is constantly exploring new plastic materials and processing technologies to improve the quality and competitiveness of its products.

The wide - spread application of plastics in these downstream fields has created a huge market demand, which in turn promotes the continuous development and expansion of the plastic industry in China. The feedback from downstream industries on product performance and quality also drives the technological innovation and improvement of the plastic industry at the upstream and mid - stream levels.

FAQ

Q1: How does China's plastic production volume compare to other major countries?

In 2023, the global plastic 总产量为 4.138 亿吨,and China's plastic production accounted for 33.3% of the total, ranking first globally. In contrast, North America accounted for 17.1%, and the EU 27+3 accounted for 12.3%. China's high production volume is due to its large - scale petrochemical industry, a large number of manufacturing enterprises, and strong domestic and international market demand. For example, Sinopec, a major Chinese petrochemical company, has a huge production capacity for plastic raw materials, which supports the high - volume production of plastic products in the country.

Q2: What are the most promising new plastic materials being developed in China?

China is actively developing several promising new plastic materials. Polylactic acid (PLA) is one of them. It is a biodegradable plastic made from renewable resources such as corn starch and sugarcane. PLA has good mechanical properties and is widely used in packaging, disposable tableware, and 3D printing filaments. Another is polyhydroxyalkanoates (PHA), which is also biodegradable and has excellent biocompatibility, making it suitable for medical applications like tissue engineering scaffolds and drug - delivery systems. Some research teams in China are also developing high - performance plastics with enhanced heat - resistance and strength, aiming to be used in aerospace and high - end manufacturing.

Q3: How are Chinese plastic companies addressing environmental concerns?

Chinese plastic companiesYigu Technology are taking multiple measures to address environmental concerns. Technological innovation is a key aspect. Many companies are investing in research and development to improve recycling technologies. For example, some are using advanced physical and chemical recycling methods to increase the recycling rate of waste plastics. They are also developing biodegradable plastics to reduce the environmental impact of plastic waste. In terms of production processes, companies are adopting cleaner production technologies to reduce emissions of pollutants. Some large - scale plastic manufacturing enterprises have installed advanced waste - gas treatment equipment to minimize the release of harmful gases during production. Additionally, many companies are strengthening cooperation with recycling enterprises to establish more complete waste - plastic recycling systems, promoting the circular utilization of resources.