Understanding the Significance of the Right Choice

Selecting the right medical plastic manufacturer is far from a trivial decision; it's a choice that wields profound influence over multiple aspects of the medical industry. At its core, this decision is intrinsically linked to the quality of medical products. High - quality medical plastics are the foundation upon which reliable medical devices are built. For instance, in the case of syringes, the plastic material must be of such high quality that it not only precisely measures the dosage but also ensures the sterility and integrity of the liquid it contains during storage and use.

Patient safety is another critical factor hanging in the balance. Substandard medical plastics can lead to a host of problems. They may leach harmful chemicals into the body when in contact with bodily fluids, which can cause allergic reactions or other health complications. In the context of implants, the wrong choice of plastic material could lead to implant failure, necessitating additional surgeries and causing great distress to the patient. According to a study by the Journal of Medical Devices, approximately 3 - 5% of medical device - related adverse events are attributed to material - related issues, many of which can be traced back to the quality of the medical plastics used.

Key Factors to Consider

Quality Assurance

Quality assurance is the bedrock of a reliable medical plastic manufacturer. Material selection is the first and most crucial step. Medical plastics must be biocompatible, meaning they do not cause adverse reactions when in contact with the human body. For example, polypropylene is often used in the production of syringes due to its excellent chemical resistance, sterility, and ability to withstand autoclaving processes. Manufacturers should source materials from reputable suppliers and conduct thorough material testing, including tests for purity, strength, and compatibility with other components in the medical device.

The production process also plays a vital role. A well - designed production flow minimizes the risk of contamination and defects. For instance, cleanroom manufacturing environments are essential for producing medical plastics. These cleanrooms are classified according to the number of particles allowed per cubic meter of air. Class 100 cleanrooms, which allow a maximum of 100 particles of 0.5 micrometers or larger per cubic foot of air, are often used for manufacturing high - risk medical devices such as implantable components.

A comprehensive quality control system should be in place. This includes in - process inspections at various stages of production. For example, during injection molding, the quality control team may check the dimensions of the molded parts, the integrity of the surface finish, and the consistency of the color. Final product inspections should be rigorous, and sampling plans should be based on statistical methods to ensure that a representative number of products are tested. The use of quality control tools such as Statistical Process Control (SPC) can help monitor and control the production process, detecting and correcting any deviations before they result in defective products.

Production Capabilities

Manufacturers need to have a wide range of production capabilities to meet the diverse needs of the medical industry. Production capacity is an important consideration. High - volume manufacturers can produce large quantities of standard medical plastic products such as syringes, catheters, and IV bags efficiently. However, for customized or low - volume products, flexibility in production is key. A manufacturer should be able to ramp up or down production according to market demand. For example, during a pandemic, the demand for certain medical plastics like face shields and respirator components skyrocketed. Manufacturers with the ability to quickly adjust their production lines were better able to meet this sudden increase in demand.

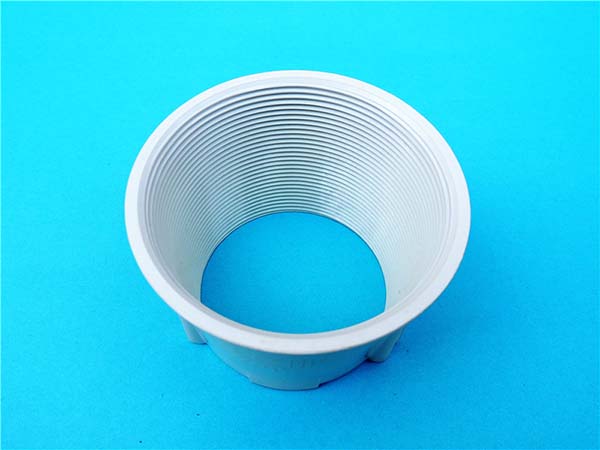

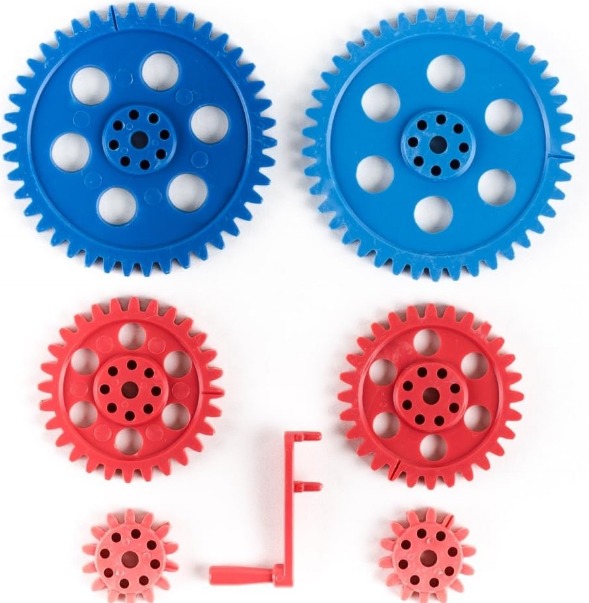

The production process also matters. Different medical plastic products require different manufacturing processes. Injection molding is commonly used for producing small, precise parts such as syringe barrels and needle hubs. Blow molding is suitable for creating hollow products like IV bags. Extrusion is often used for manufacturing long, continuous products such as plastic tubing. A manufacturer that offers multiple production processes can provide a one - stop solution for customers, reducing the need for multiple suppliers and streamlining the supply chain.

Advanced equipment is another aspect of production capabilities. State - of - the - art injection molding machines can offer higher precision, faster cycle times, and better control over the molding process. Automated equipment can also improve the consistency and quality of products while reducing labor costs. For example, automated assembly lines can accurately assemble complex medical devices with a high degree of repeatability, ensuring that each product meets the required quality standards.

Regulatory Compliance

Regulatory compliance is non - negotiable in the medical plastic manufacturing industry. The medical industry is highly regulated to ensure patient safety. Manufacturers must comply with a variety of regulations and standards. In the United States, the Food and Drug Administration (FDA) has strict guidelines for medical device manufacturing, which includes the use of medical plastics. The European Union has its own set of regulations under the Medical Device Directive (MDD) and the new Medical Device Regulation (MDR). These regulations cover aspects such as product design, material safety, manufacturing processes, and labeling.

Compliance with ISO standards is also crucial. ISO 13485, for example, is an international standard specifically for the medical device quality management system. It outlines requirements for design, development, production, installation, and servicing of medical devices, ensuring that manufacturers maintain a high level of quality and safety throughout the product lifecycle. Non - compliance with these regulations can lead to severe consequences, including product recalls, fines, and damage to the manufacturer's reputation. For instance, a manufacturer that fails to meet the FDA's Good Manufacturing Practice (GMP) requirements may face a halt in production and significant financial losses.

Cost - effectiveness

Cost - effectiveness is a factor that cannot be overlooked when choosing a medical plastic manufacturer. While it may be tempting to choose the lowest - priced option, it's essential to consider the overall value. Price is an obvious consideration, but it should not be the sole determinant. A lower - priced product may come with hidden costs, such as lower quality, higher defect rates, or shorter product lifespan. For example, a cheaper plastic for a medical implant may require more frequent replacements, leading to higher costs in the long run.

Cost - effectiveness also involves considering the value - for - money aspect. A manufacturer that offers high - quality products at a reasonable price is more cost - effective in the long term. This may include products with better performance, longer durability, and fewer quality - related issues. Additionally, factors such as the manufacturer's ability to provide cost - saving solutions, like efficient production processes that reduce waste, should be considered.

Long - term costs should also be factored in. This includes costs associated with product maintenance, repairs, and replacements. A reliable medical plastic manufacturer will produce products that minimize these long - term costs. For example, a well - made medical device made from high - quality plastics may require less frequent servicing, reducing the overall cost of ownership for the end - user.

Comparison Table: Top Medical Plastic Manufacturers

To further assist you in your decision - making process, here is a comparison table of some well - known medical plastic manufacturers based on the key factors we've discussed:

| Manufacturer | Quality Assurance | Production Capabilities | Regulatory Compliance | Cost - effectiveness |

| Manufacturer A | Utilizes top - tier biocompatible materials sourced from renowned suppliers. Stringent in - process and final inspections with SPC implementation. | High - volume production capacity. Offers injection molding, blow molding, and extrusion. Equipped with advanced automated equipment. | Complies with FDA, MDR, and ISO 13485 standards. | Higher initial price but long - term cost - savings due to low defect rates and longer product lifespan. |

| Manufacturer B | Good material selection but less comprehensive in - process inspections. | Medium - volume production. Specializes in injection molding but has limited other processes. Equipment is somewhat outdated. | Complies with FDA and basic ISO standards. | Lower price, but higher defect rates may lead to long - term costs. |

| Manufacturer C | Material quality is average. Quality control is mainly focused on final product inspection. | Low - volume production with flexibility for customization. Limited to injection molding. Basic equipment. | Meets minimum regulatory requirements in some regions. | Lowest price, but risks associated with quality may be high. |

This table provides a snapshot of how different manufacturers stack up against each other. However, it's important to note that this is a simplified comparison, and in - depth research and communication with each manufacturer are still necessary to make the best choice for your specific needs.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology understands the nuances of the manufacturing industry. When it comes to choosing a medical plastic manufacturer, we emphasize the importance of customization capabilities. Every medical device has unique requirements, and a manufacturer that can offer tailored solutions is invaluable. Yigu Technology itself prides itself on its ability to work closely with clients to create custom products, and we believe medical plastic manufacturers should follow a similar approach.

Flexibility in cooperation is another key point. The medical industry is dynamic, with changing demands and urgent needs. A medical plastic manufacturer should be able to adapt quickly, whether it's adjusting production schedules or modifying product designs. Yigu Technology values this flexibility in our own partnerships, and we think it's essential for medical plastic manufacturers to be responsive to their customers' evolving needs.

Frequently Asked Questions

Q1: How can I ensure the quality of medical plastic products?

To ensure the quality of medical plastic products, first, check if the manufacturer has relevant quality certifications such as ISO 13485. This certification indicates that the manufacturer follows strict quality management systems. Second, inquire about their testing processes. Reliable manufacturers conduct tests on raw materials for biocompatibility, strength, and purity. They also perform in - process and final product inspections. For example, they may use X - ray inspection to detect internal defects in molded parts. Additionally, know the source of their materials. Reputable suppliers are often a sign of better - quality raw materials.

Q2: What are the common materials used in medical plastics?

Common materials used in medical plastics include Polyvinyl Chloride (PVC), Polypropylene (PP), and Polyethylene (PE). PVC is flexible and has good chemical resistance, often used in blood bags and tubing. However, it may contain plasticizers that need to be carefully monitored for safety. PP is lightweight, has excellent chemical resistance, and can withstand high - temperature sterilization, making it suitable for syringes and some implantable components. PE is also chemically resistant and is used in applications like IV bags due to its flexibility and cost - effectiveness.

Q3: How to negotiate a reasonable price with the manufacturer?

Before negotiation, research the market price range of similar medical plastic products to have a clear understanding of what is reasonable. Consider placing a larger order, as many manufacturers offer quantity discounts. Long - term cooperation can also be a bargaining chip. You can propose signing a long - term supply contract in exchange for more favorable pricing. For example, if you commit to purchasing a certain amount of products over a year, the manufacturer may be more willing to lower the unit price.